Volume 3, Issue 2

Insights in Analytical Electrochemistry

ISSN: 2470-9867

Analytical Chemistry-Formulation 2017

August 28-30, 2017

Page 24

8

th

Annual Congress on

&

14

th

International Conference and Exhibition on

August 28-30, 2017 Brussels, Belgium

Analytical and Bioanalytical Techniques

Pharmaceutical Formulations

Optimizing early phase development of amorphous solid dispersion formulation thorough application

of modeling tools

Samuel Kyeremateng

AbbVie Deutschland GmbH & Co. KG, Germany

Statement of the Problem:

Amorphous Solid Dispersion (ASD) is an established formulation technique for improving the

bioavailability of poorly water-soluble Active Pharmaceutical Ingredients (APIs) by increasing solubility, wettability and

dissolution rate. Successful manufacturing of ASD formulation by Hot Melt Extrusion (HME) requires selection of e.g. the

right API load, excipients, and processing temperature. API load is also crucial in determining important quality attributes of

the drug product such as long term physical stability to ensure consistent product performance during its self-life. Identifying

the possible maximum drug load limit and excipients for HME feasibility and risk assessment, and long-term physical stability

of the manufactured ASD can be quite challenging whereby several extrusion trials are required in addition to prolonged

stability studies. Exploring the optimal design space during early phase of formulation development by this approach requires

significant amount of resources including API which may be limitedly available during this phase.

Methodology&TheoreticalOrientation:

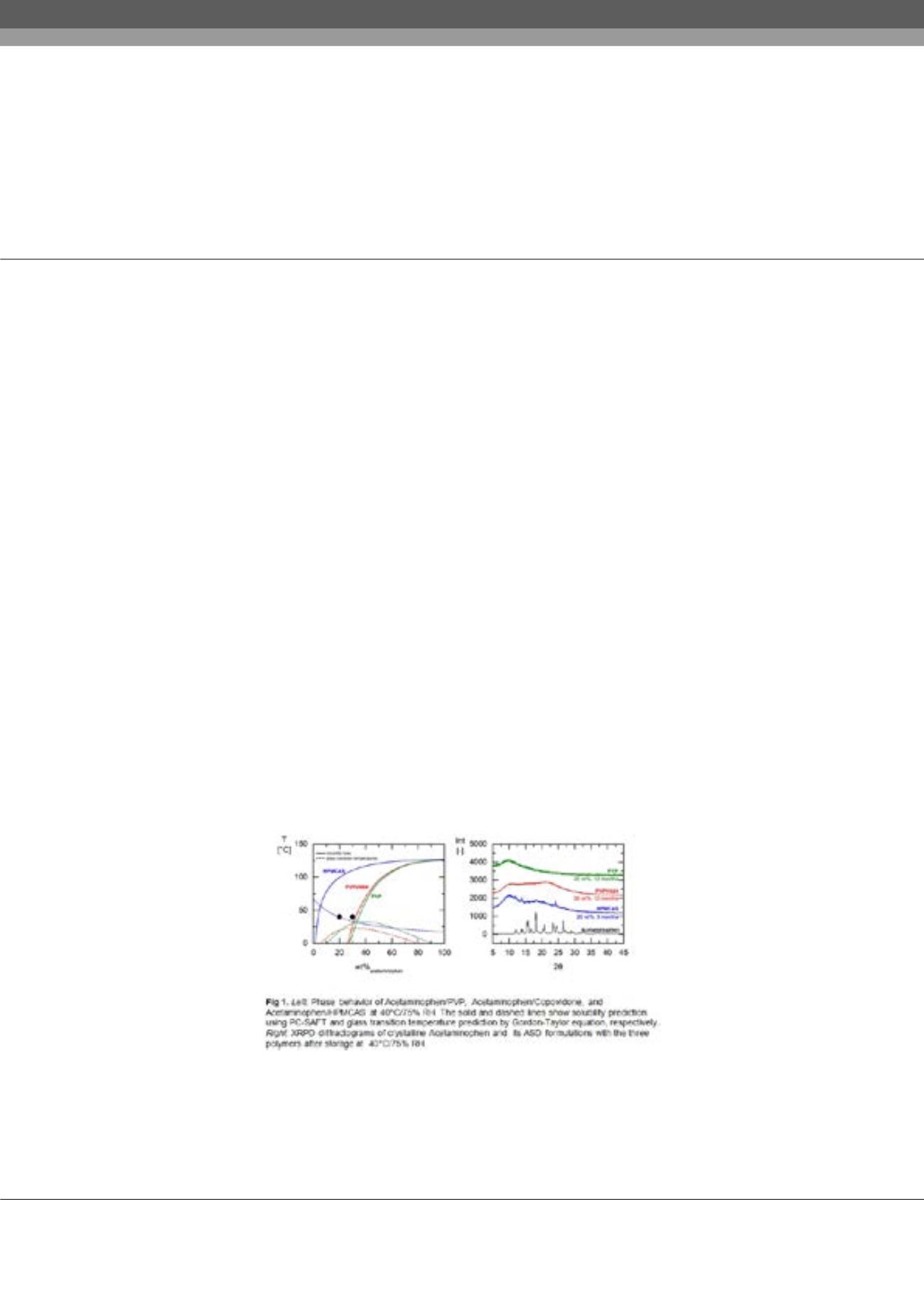

As anAPI-sparing approach, novel empiricalmodel and the rigorous thermodynamic

Perturbed Chain Statistically Associating Fluid Theory (PC-SAFT) were applied to model ASD phase diagram of several

formulations to effectively and quickly explore the design space to optimize formulation development. These were followed up

with HME manufacturing and long-term stability studies (up to 18 months) of the formulations under ICH conditions to verify

the model-predicted results. Several APIs and polymeric excipients including Soluplus, Copovidone, PVP, and HPMCAS were

used in the studies.

Findings:

The modeling tools were found to be very suitable in estimating extrusion temperature required for generating

crystal-free ASD formulations as well as predicting their physical stability under different storage conditions, i.e., temperature

and relative humidity.

Conclusion & Significance:

Recent advances in predictive ASD phase diagram modeling proved to be reliable tools for

excipient selection, HME temperature prediction, and designing ASD formulations for maximum drug load and physical

stability. Applying these tools enables successful ASD formulation optimization using less resources and materials.

Biography

Samuel Kyeremateng is a Senior Scientist in the Global Pharmaceutical Sciences Division at AbbVie Deutschland in Ludwigshafen. His research activities focus

on scientific advances in the understanding of amorphous molecular solids, and development and application of models in predicting with confidence the preferred

composition, manufacturing process, and stability of amorphous solid dispersion formulations. His current responsibilities at AbbVie Deutschland include leading

the Material Science Group that supports formulation development, and mentoring Doctorate research students and other scientists within the company. He

received his Doctorate in Polymer Science from Martin-Luther-Universität in Germany.

samuel.kyeremateng@abbvie.comSamuel Kyeremateng, Insights in Analytical Electrochemistry, 3:2

DOI: 10.21767/2470-9867-C1-002