Page 32

Notes:

conferenceseries

.com

Polymer Sciences | ISSN: 2471-9935

October 02-03, 2017 Chicago, USA

3

rd

International Conference on

Polymer Science and Engineering

Optimization of thermal and mechanical properties of unsaturated polyester resin as a binder in polymer

concrete for manufacturing precision tool machine base

Header Haddad

1

and

Igor Sbarski

2

1

Swinburne University of Technology, Australia

2

RMIT University, Australia

T

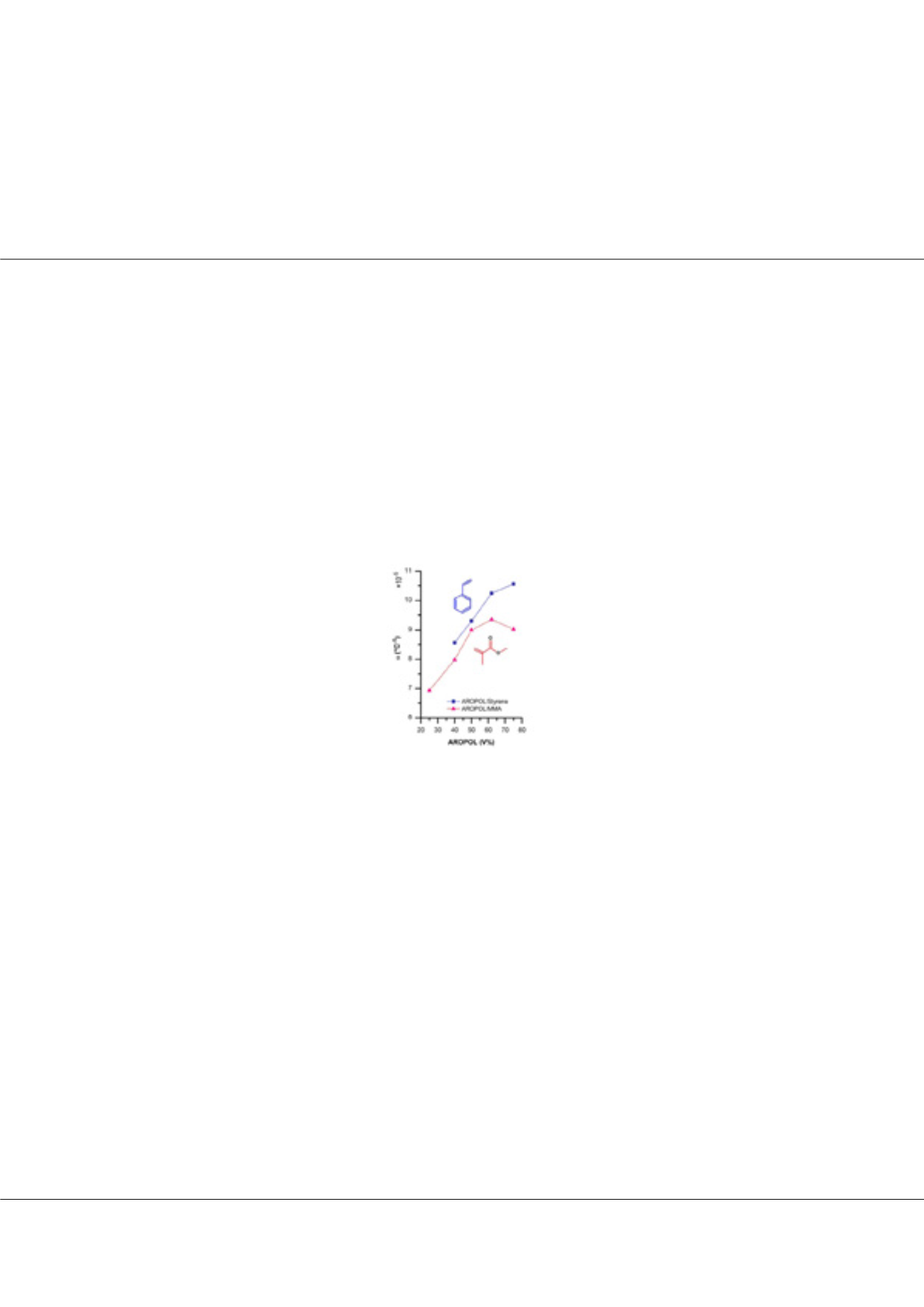

his study investigates the effect of unsaturated polyester resin chemical composition on the coefficient of thermal expansion,

damping properties, flexural strength, tensile strength and hardness. The resin was used as binder in polymer concrete for

manufacturing the base of precision tool machine. Resins of various ratios of styrene-ARAPOL and methyl methacrylate (MMA)-

ARAPOL were made and curing kinetics were followed using viscosity measurements and exothermic reaction temperature profile.

The resins were studied using dynamic mechanical analysis and in house thermal expansion measuring devices. It was found

that ARAPOL–MMA (60:40) has the highest damping factor 5.46%, and the thermal expansion coefficient of 7.98×10

-5

/°C. This

composition also has the optimum flexural strength and tensile strength at 128 MPa and 5.86 MPa.

Biography

Header Haddad has expertise in evaluation and passion in improving the thermosetting polymer for composite materials in manufacturing the base of precision tool ma-

chine. His approach is based on application requirements and how to develop new methods to optimize the composite material through polymer and the aggregates of the

composite materials. Another applications that Header researched are injection moulding and blow moulding. Headers research is all industrial based in connection with

well-known companies such as ANCA.

headerhaddad@swin.edu.auHeader Haddad et al., Polym Sci, 3:3

DOI: 10.4172/2471-9935-C1-002

Figure: Coefficient of thermal expansion of MMA and styrene – AROPOL resins.