NanoMat 2018

Nano Research & Applications

ISSN: 2471-9838

Page 63

April 26-27, 2018

Rome, Italy

17

th

Edition of International Conference on

Emerging Trends in

Materials Science and

Nanotechnology

F

ibre reinforced polymeric (FRP) are used in different

components of aerospace, space, marine, automobile and

civil infrastructure. These materials are becoming prime choice

of materials in the field of structural components. During their

in-service period different structural components experience a

wide range of loadings. The current investigation was focused

on the assessment of mechanical and thermal behavior of

glass FRP composite on the addition of nano-TiO

2

particles. The

control glass/epoxy(GE) composites and nano-TiO

2

modified

GE composites were tested at different crosshead speeds viz.

1, 10, 100, 500 and 1000 mm/min. nano-TiO

2

was used as filler

material and the epoxy matrix was processed with different nano-

TiO

2

contents (0.1, 0.3 and 0.5 wt. %). Addition of 0.1 wt. % nano-

TiO

2

particles exhibited an improvement in strength of nano-

TiO

2

/GE composites at all crosshead speeds. Different failure

patterns of nano-TiO

2

enhanced GE composite tested at 1, 10,

100, 500 and 1000 mm/min crosshead speeds were identified.

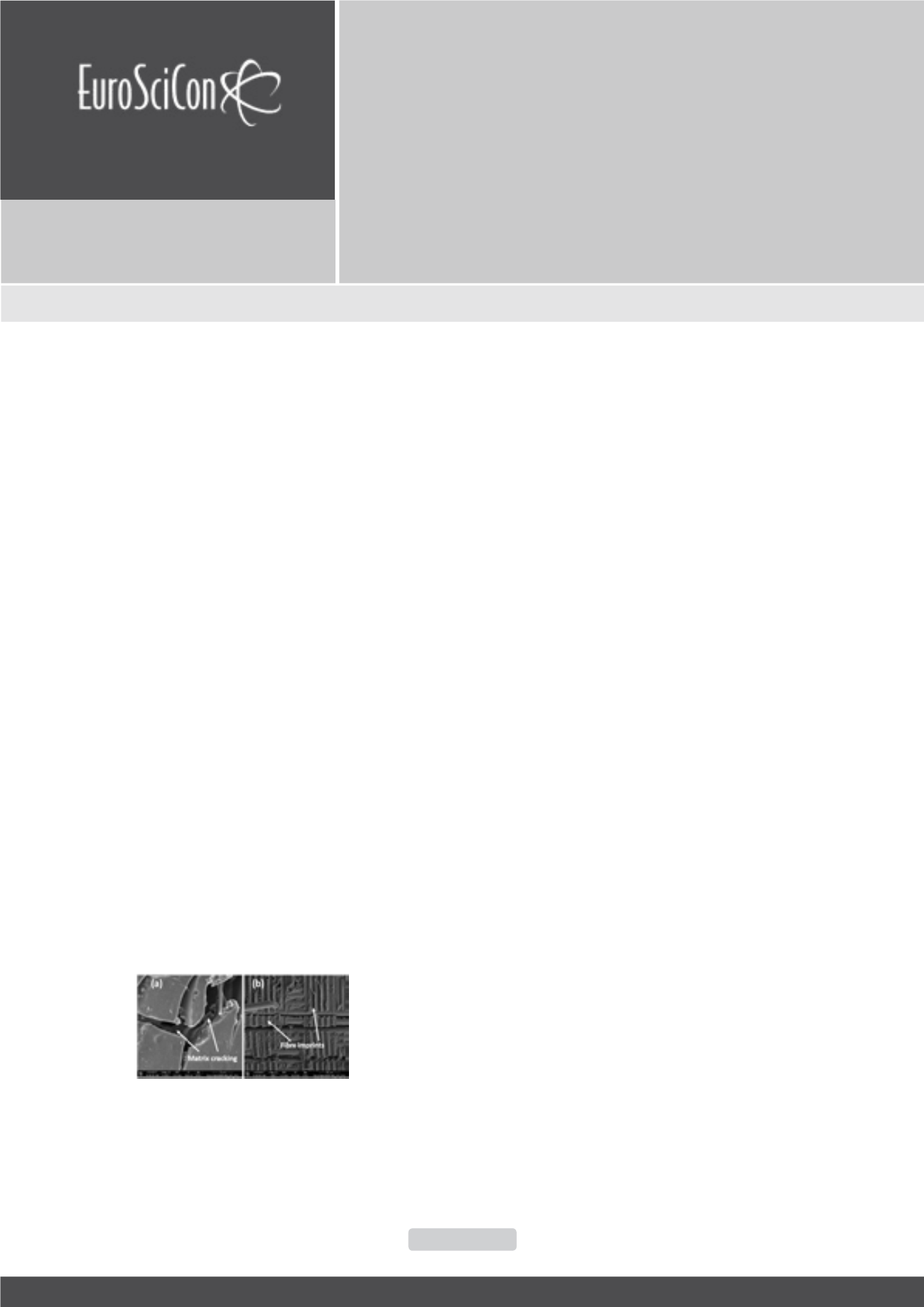

Scanning electron microscopy (SEM) was carried out to know

the main cause of failure that induced different morphologies.

Furthermore, the viscoelastic behavior of the material was carried

out using dynamic mechanical thermal analyzer which correlated

the mechanical and thermo-mechanical behavior of the FRP

composites.

Recent Publications

1. Mahato K K, Dutta K, Ray B C (2018) Loading rate

sensitivity of liquid nitrogen conditioned glass fiber

reinforced polymeric composites: An emphasis on

tensile and thermal responses, Journal of Applied

Polymer Science, 135:9.

2. Mahato K K, Dutta K, Ray B C (2017) High-temperature

tensile behavior at different crosshead speeds during

loading of glass fiber-reinforced polymer composites,

Journal of Applied Polymer Science, 134: 16.

3. Mahato K K, Rathore D K, Dutta K, Ray B C (2017)

Effect of loading rates of severely thermal-shocked

glass

fiber/epoxy

composites,

Composites

Communications, 3: 7-10.

4. Mahato K K, Dutta K, Ray B C (2017) Static and Dynamic

Behavior of Fibrous Polymeric Composite Materials

at Different Environmental Conditions Journal of

Polymers and the Environment, 1-27.

5. NayakRK,MahatoKK, RayBC, (2016)Water absorption

behavior, mechanical and thermal properties of

nano TiO

2

enhanced glass fiber reinforced polymer

composites, Composites Part A: Applied Science and

Manufacturing 90:736-747.

Biography

Kishore Kumar Mahato is pursuing PhD at National Institute of Technology,

Rourkela, India. He has published around 15 research articles in different SCI

and Scopus indexed journals. The research work is focused on failure and

fracture behavior of fibre reinforced polymeric Composite in different harsh

environments. Investigations are focused on the assessment of mechanical

behavior of environmentally conditioned FRP composites through experi-

mental and numerical analysis. Primarily, the polymer matrix and the exist-

ing fibre/polymer interface are susceptible to harsh and hostile in-service

environments which can alter the durability and integrity of fibrous polymer-

ic composites. The mechanical response of polymeric materials is loading

rate sensitive and the precise mode of failure depends on the in-service en-

vironment. The environmental parameters which may influence the perfor-

mance of the composites includes but not limited to temperature, moisture,

UV and other high energy radiations.

kishorepce@gmail.comMechanical and thermal behavior of nano-TiO

2

enhanced glass

fibre reinforced polymeric composites at various crosshead speeds

Kishore Kumar Mahato

1

, Krishna Dutta

2

and

Bankim Chandra Ray

3

1

Ph D Scholar, Department of Metallurgical and Materials Engineering, NIT Rourkela, India

2

Ph D, Department of Metallurgical and Materials Engineering, NIT Rourkela, India

3

Ph D, Department of Metallurgical and Materials Engineering, NIT Rourkela, India

Kishore Kumar Mahato et al., Nano Res Appl, Volume:4

DOI: 10.21767/2471-9838-C1-008

Figure 1:

Scanning electron micrographs showing (a) matrix

cracking (b) fibre imprints.