Volume 4

Nano Research & Applications

ISSN: 2471-9838

JOINT EVENT

October 04-05, 2018 Moscow, Russia

&

2

nd

Edition of International Conference on

26

th

International Conference on

Advanced Nanotechnology

Materials Technology and Manufacturing Innovations

Advanced Nanotechnology 2018

& Materials-Manufacturing 2018

October 04-05, 2018

Page 66

Octavio Manuel Pereira

University of the Basque Country, Spain

Octavio Manuel Pereira, Nano Res Appl 2018, Volume 4

DOI: 10.21767/2471-9838-C5-020

Cryogenic lubri-coolant machining on difficult-to-cut alloys

N

owadays, environmental consciousness is taking relevance in the society. This situation involves some consequences

in the manufacturing processes with the aim of improving this philosophy. In the particular case of machining

operations, the target is reducing the use of cutting fluids to assist the process. It has to be taken into account that

these cutting fluids are based on mineral oils and consequently, its use is environmentally inefficient. Besides, according

to several authors, its use represents between 17% and 30% of the total manufacturing costs. Therefore, looking for

other lubricooling alternatives is a big challenge to be faced. Among these alternatives, CryoMQL, which combines CO

2

cryogenic cooling and MQL, is presented as a full solution reaching a balance between environmental and economic

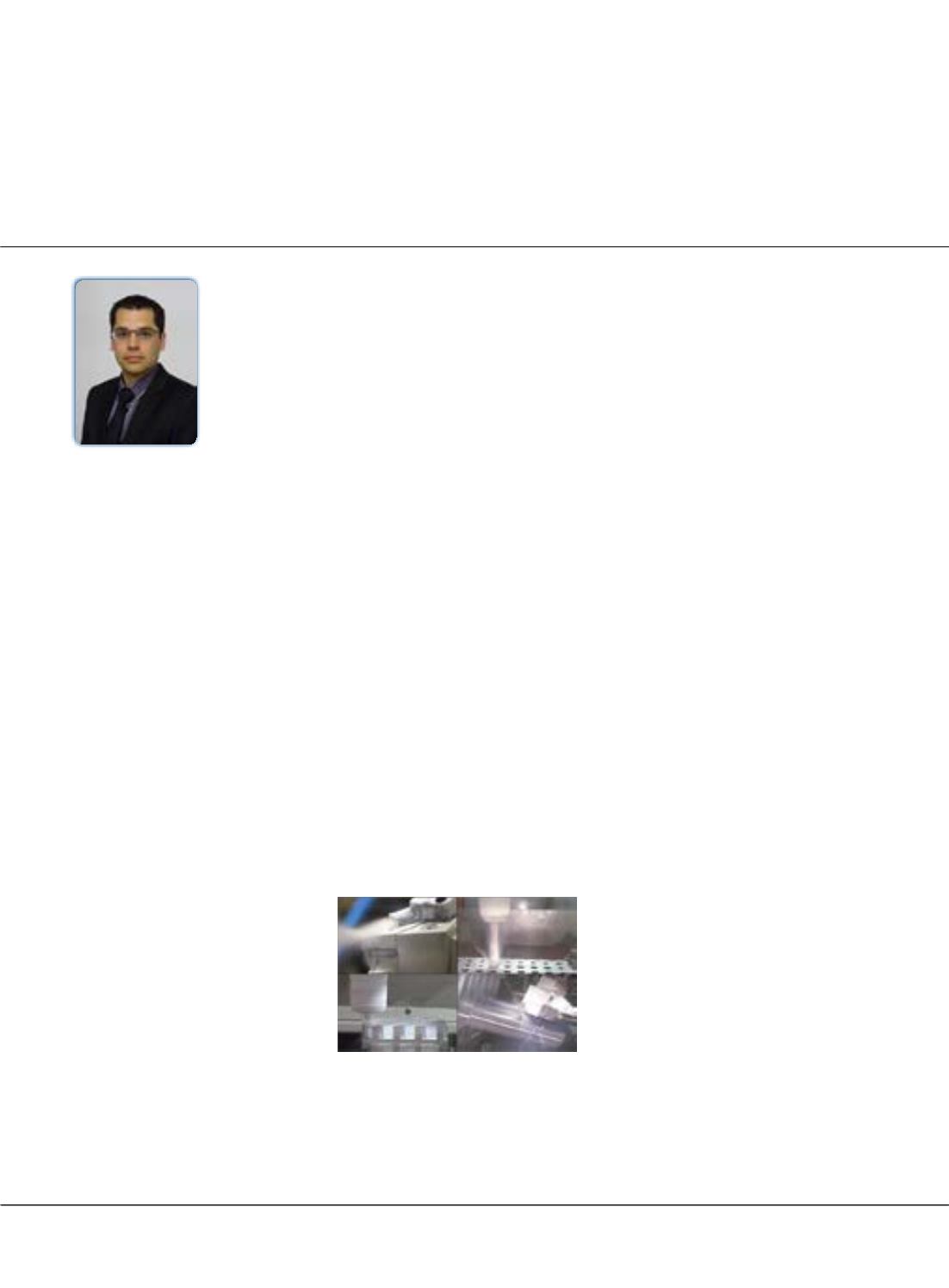

issues. In the figure several performances of its use are shown. Furthermore, this lubricooling technique takes relevance

during the machining processes of heat-resistant super alloys. The use of these alloys, known also as difficult-to-cut

materials, is growing worldwide in aeronautical industry related to turbomachinery components. In particular, Inconel

718 super alloy is one of the most used materials in this sector to manufacture turbofan critical components due to

its high hardness combined with a good tensile strength at high temperatures. However, this material presents some

challenges during machining processes leading to high cutting forces, low material removal rates, and other problems

that may cause premature tool breakage which needs to be avoided. Therefore, in order to improve milling processes

in Inconel 718, in this paper is presented a new lubricooling technique of applying CryoMQL in which CO

2

is used as

internal tool coolant with the aim of reducing its consumption. The results show that its use improves the current process,

not only from an environmental point of view, but also from economic and technical point of view, reaching a technology

known as ECO2 milling performance (economy+ecology).

Recent Publications

1. González H, Calleja A, Pereira O, Ortega N, López de Lacalle LN and Barton M (2018) Super abrasive machining

of integral rotary components using grinding flank tools. Metals 8:24.

2. Pereira O, Martín-Alfonso J.E., Rodríguez A, Calleja A, Fernández-Valdivielso A and López de Lacalle LN

(2017) Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological