NanoMat 2018

Nano Research & Applications

ISSN: 2471-9838

Page 74

April 26-27, 2018

Rome, Italy

17

th

Edition of International Conference on

Emerging Trends in

Materials Science and

Nanotechnology

T

he surface condition of a component is usually the most

important engineering factor affecting its performance.

Almost inevitably the outer surface of a workpiece is subjected to

wear,fatigueandcorrosionwhileitisinservice.Averageroughness

(Ra) is important feature of the surface. It contributes slide wear,

friction, corrosion, oxidation, fatigue, physical properties (optical,

electrical, and thermal properties) and esthetic. Laser as a source

of high concentrated heating energy was used successfully in

surface treating of ferrous material products. Laser heating or

meltinginducesphasetransformationandstructuralchanges,also

low distortion with minimal disruption. These changes affect the

surface roughness either negatively or positively that is depending

on the processing set of parameters. Laser processing variables

comprise that related to laser source (power intensity, operation

mode and wavelength) and to the material (physical properties,

surface absorptivity and geometry) in addition to laser scanning

speed and shrouding gas flow rate. [8]. To avoid post processing

and get preferred surface roughness the relation between laser

parameters and surface roughness is to be investigated for a

given material. Many researchers study the effect of laser cutting

and heat treating parameters on surface roughness. In this work

investigation of the effect of processing variables on the average

surface roughness (Ra) of gray cast ironmelted by CWdiode-fiber

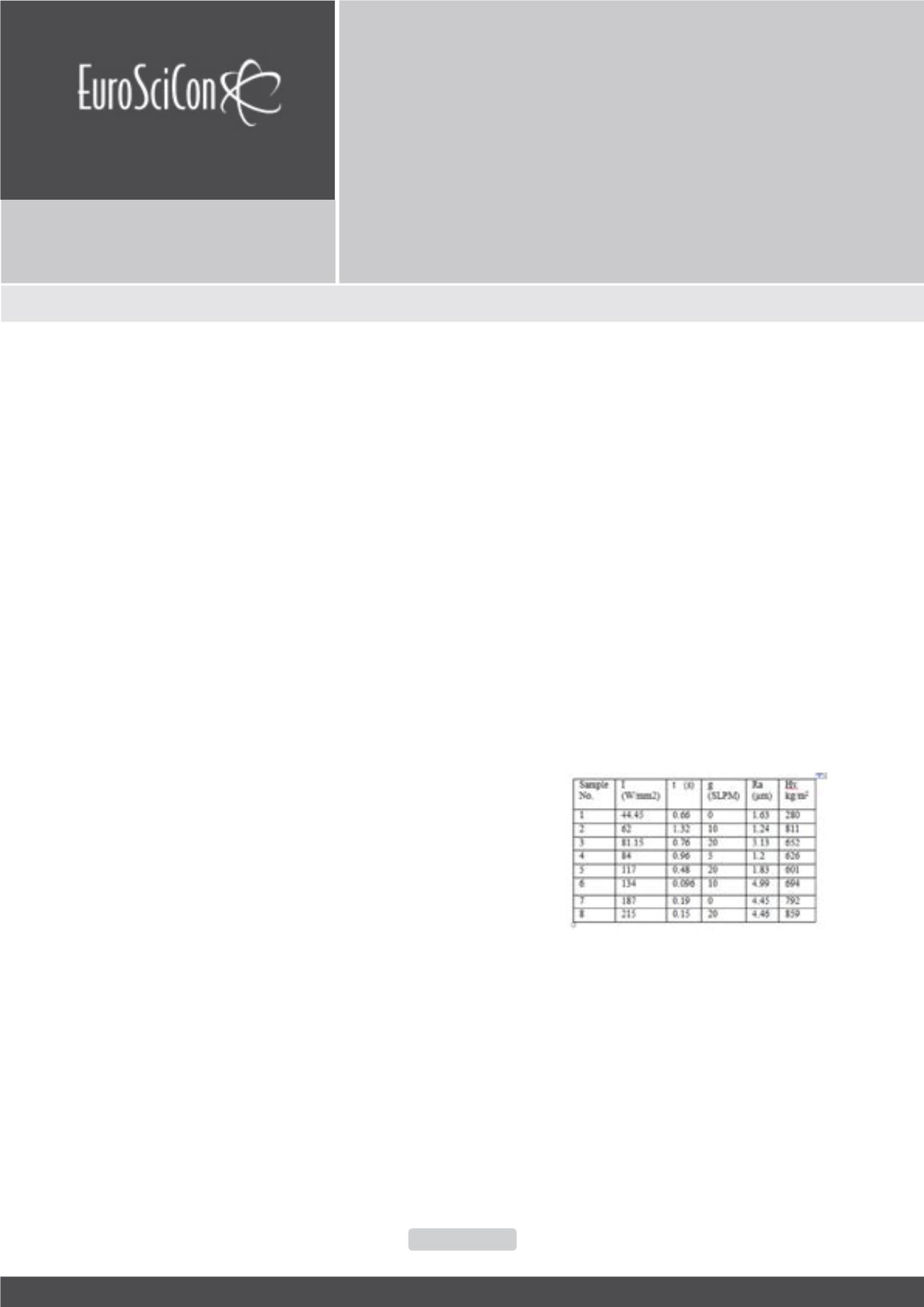

Yb:YAG laser. Power intensity (I), time of interaction (t), and gas

flow rate (g) were used as variables. It is found that for power

intensities that maintain melting, decreasing time of interaction,

increasing shrouding gas flow rate or increasing both of them led

to increased average surface roughness. Table 1 represents the

processing parameters via the resulted microhardness and the

average surface roughness.

Recent Publications

1. Rehab H. Khanjar, Mohammed J. Khadhim and Adil

Abbas Alwan, 2017. Experimental investigation of

melting gray cast iron by laser. Journal of Material

Science Engineering Volume 6 Issue 5(Suppl) pp 77.

2. Rehab H. Khanjar, “ Analysis of gray cast iron

microstructure and hardening by using Yb:YAG Laser”,

PhD Thesis series, University of technology/Baghdad.

3. Mohammed J. Kadhim Rehab H. Khanjar and Adil Abass

Alwan. 2016. Performance evaluation of laser melting

gray cast iron. , The First International Conference for

Engineering Researches ICER(1-2/3/2017) Middle

Technical University, Baghdad, Iraq.

4. Khayria Salman, Rehab H. Khanjar and Shada M. Rajaa,

2011. The Effect of Liquid Nitriding and Carborizing

on Adhesive Wear resistance of carbon steel 1020.

Engineering & Technology Journal V 29, essue 5, pp

231-240.

Figure 1:

Nano particles and their effect on yield and economics of B.

juncea

Biography

Fifteen years of working research experience at National dairy Development

Board, CAR C-NEH Region, Directorate of Rapeseed-Mustard Research

and ICAR-Indian Agricultural Research Institute, New Delhi. Specialized in

farming system research under hill and shifting cultivation for higher in-

come, micro-irrigation and resource conservation technologies in mustard

based cropping system. Handled externally funded and institute projects.

Published >65 international and national research papers, ten bulletin, four

extension folders, 15 book chapters and one book. Also handled 10 exter-

nally funded project including World Bank sponsored and 12 institutional

projects.

rehab@leetani.comThe Effect of laser melting on the gray cast iron surface

roughness

Rehab Hussein Khanjar

Dr., Middle Technical University, Institute of Technology/Baghdad, Iraq

Rehab Hussein Khanjar, Nano Res Appl, Volume:4

DOI: 10.21767/2471-9838-C1-009