Nano Research & Applications

ISSN: 2471-9838

April 26-27, 2018

Rome, Italy

NanoMat 2018

Page 16

17

th

Edition of International Conference on

Emerging Trends in

Materials Science and

Nanotechnology

A

mong

multifunctional

materials

magnetoelectric

multiferroics are a special class with coupled ferromagnetic

and ferroelectric orders. They are particularly appealing because

they not only show the characteristic of the single ferroic

orders where the electric field

E

, magnetic field

H

, and stress σ

control the electric polarization

P

, magnetization

M

, and strain

ε, respectively, but also because interactions between them

lead to additional functionalities. Therefore in a magnetoelectric

multiferroic,

H

may control

P

or

E

may control

M

. In composite

materials the electric and magnetic degrees of freedom are

located in different components and are interfacially coupled

to each other. Several applications, including magnetic sensors,

high-frequency inductors, memory devices, and high-frequency

signal processing devices, (very high-density memory storage

media) have been proposed and demonstrated. Nanopowders

are mainly synthesized by solid state synthesis, coprecipitation,

hydrothermal and sol-gel methods and the magnetic properties

vary by changing the processing parameters and/or the

stoichiometry. The magnetostrictive and piezoelectric materials

used as constituents of magnetoelectric (ME) composites are

ferromagnetic oxides, including ferrites like cobalt ferrite (CFO),

manganites, 3d-transition metals/alloys for the magnetic phase

and lead zirconate titanate (PZT), barium titanate (BTO), or lead

magnesium niobate-lead titanate (PMN-PT) for the ferroelectric

phase. Bulk and thin or thick film structure are produced where

the connectivity of the phases plays a critical role; and the 3-0

type particulate structure, 2-2 type laminate structure and the

1-3 type cylinder matrix are the most frequently investigated.

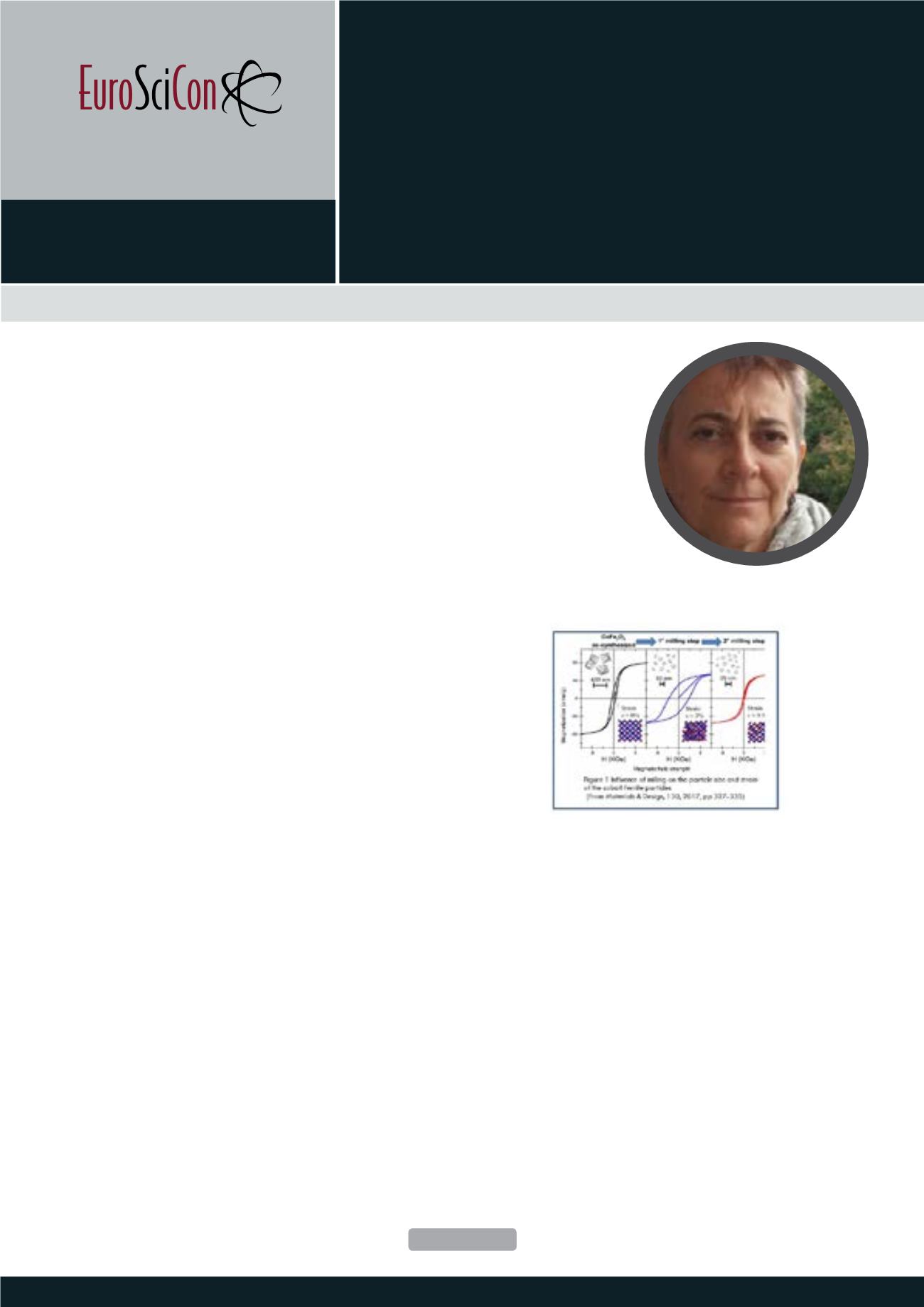

The influence of the processing on the microstructure and

final properties is shown for PZT-CFO particulate and laminate

composites with focus on the role played by the milling and

densification treatments that allow producing high- and low-

coercivity nanosized cobalt ferrite nanoparticles and fully dense

composites.

Recent Publications

1. Srinivasan G, Priya S and Sun N X (ed) (2015)

Composite magnetoelectrics: materials, structures,

and applications, Cambridge: Woodhead, ISBN: 978-1-

78242-254-9.

2. Galizia P, Ciuchi I V, Gardini D, Baldisserri C and Galassi

C (2016) Bilayer film based on composite CoFe

2

O

4

/TiO

2

and niobium-doped PZT by electrophoretic Deposition

Journal of the European Ceramic Society 36(2):373–

380.

3. Galizia P, Baldisserri C, Capiani C and Galassi C (2016)

Multiple parallel twinning overgrowth in nanostructured

dense cobalt ferrite. Materials and Design 109:19–26.

4. Galizia P, Ciomaga C E, Mitoseriu L and Galassi C (2017)

PZT-cobalt ferrite particulate composites: densification

and lead losses control by quite-fast sintering Journal

of the European Ceramic Society 37:161–168.

5. Galizia P, Cernea M, Mihalache V, Diamandescu L,

Maizza G and Galassi C (2017) Easy batch-scale

production of cobalt ferrite nanopowders by two-

Multiferroic ceramic composites: processing

and microstructure

Carmen Galassi

Institute of Science and Technology for Ceramics - National Research Council of Italy, Italy

Carmen Galassi, Nano Res Appl, Volume:4

DOI: 10.21767/2471-9838-C1-007