Volume 3, Issue 2 (Suppl)

Trends in Green chem

ISSN: 2471-9889

Environmental & Green Chemistry 2017

July 24-26, 2017

Page 78

5

th

International Conference on

6

th

International Conference on

July 24-26, 2017 Rome, Italy

Environmental Chemistry and Engineering

Green Chemistry and Technology

&

Green design of lock-and-key affinity devices to address API purification challenges

Raquel Viveiros

1,2

, William Heggie

2

and

Teresa Casimiro

1

1

Universidade NOVA de Lisboa, Portugal

2

Hovione FarmaCiencia, Portugal

Statement of the Problem:

Pharmaceutical industry spends a very significant amount of its financial resources in API (Active

Pharmaceutic Ingredients) purification processes to comply with impurity limits imposed by regulatory agencies (FDA and EMEA).

To address this worldwide demand, several purification materials have been proposed, such as molecular imprinted polymers (MIPs).

These lock-and-key affinity materials can be produced by different conventional approaches. In the last years, the use of the Green

Chemistry principles has changed the way polymers can be produced. Green technologies applied to MIP development are appearing

not only due the environment issues but also by the features of the final product and cost-effective production from the point of view

of industry. MIPs have been developed in our lab using supercritical carbon dioxide (scCO

2

) technology. These affinity materials have

been obtained for wide range of applications, namely pharmaceutical impurity removal, enrichment of natural products, removal of

contaminants from diesel and fromwater ressources. Lock-and-key affinity materials are obtained as ready-to-use and easy-to-handle

dry-powders of homogenous particle sizes, without organic solvent residues.

Methodology &Theoretical Orientation:

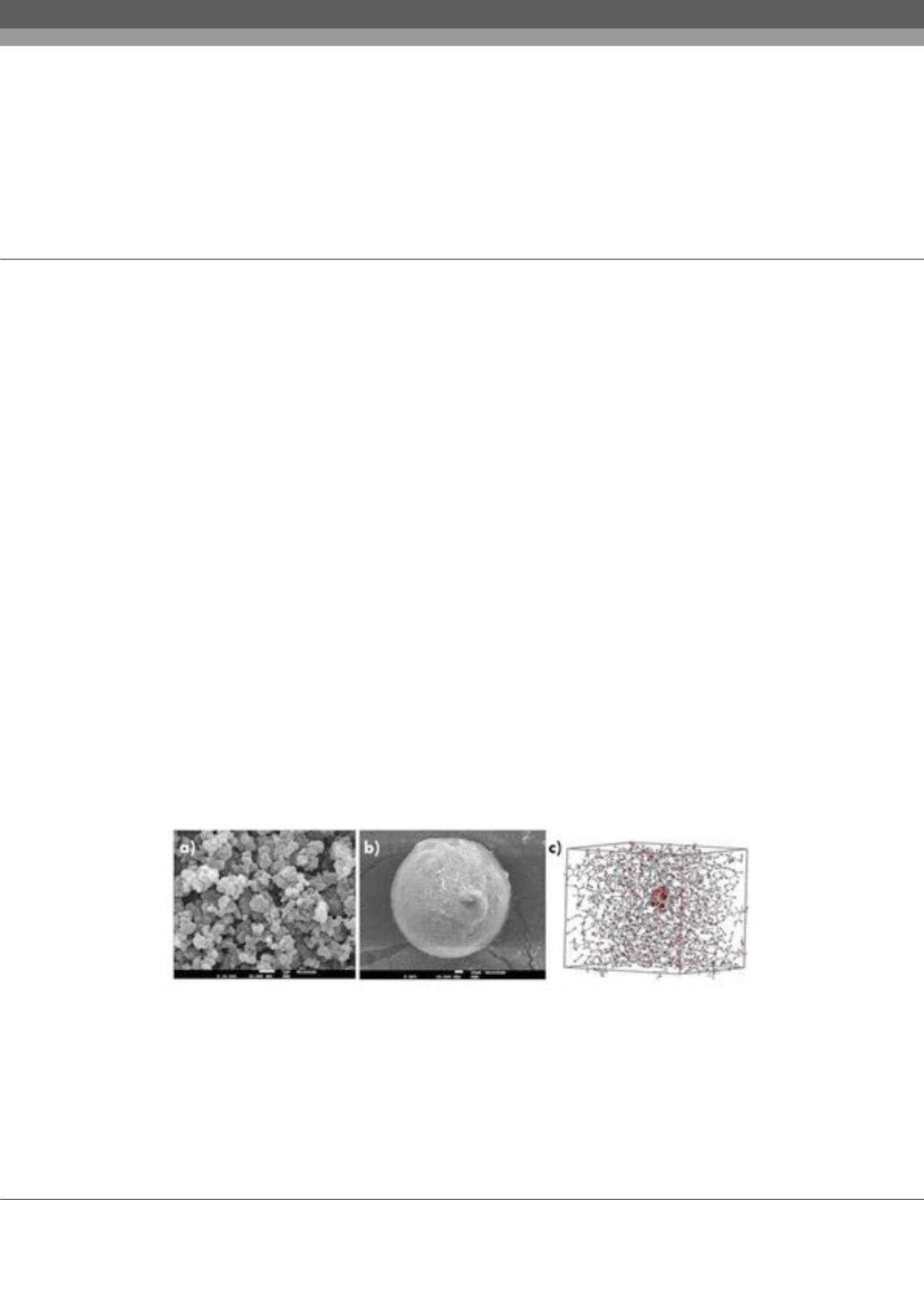

With the aim of achieving lock-and-key affinity materials to address efficiently API pharma

demand, several strategies were explored using scCO

2

(Figure 1). Herein we show three case studies, including (i) the synthesis of

high affinity polymers for API impurity; (ii) the production of large core-shell affinity beads for gravity-driven purification processes

and (iii) the use of computational tools to perform the rational design and optimization of the affinity materials, in which the CO

2

was

introduced for the first time as the solvent in the molecular modelling simulations, for a cheaper and less time-consuming processes.

Conclusion & Significance:

The affinity materials produced in scCO

2

are obtained in a green way, bringing advantages to the process

itself such as by reducing the use of organic solvents, and mechanical crushing and sieving compared to conventional processes, as

well as to advantages over other affinity molecules such as antibodies and enzymes: they are stable over harsh pH, pH and temperature

conditions, they are reusable and robust, whilst obtained in high purity and ready-to-use. In addition, results obtained in the 3

examples mentioned above revealed a good performance in API impurity removal. We also show that computational approaches are

an added-value tool and key advantage in the rational design of the best affinity systems when using a green technology, avoiding hard

and time-consuming screening methodologies and consequently reducing time and organic solvents consumption.

Figure 1:

Different approaches on lock-and-key affinity devices for API purification.

Biography

Raquel Viveiros is finishing her PhD project in Sustainable Chemistry in collaboration between NOVA University of Lisbon and a pharmaceutical company Hovione.

She performed a short training ship at the Prof. Sergey Pilestky´s Biotechnology group at University of Leicester on solid-phase synthesis and molecular modeling

systems. She also worked as Research Fellow in the several projects related to the development of affinity devices for different applications. Her multidisciplinary

professional background covers green chemistry, organic and analytical chemistry, molecular recognition, molecular imprinting, process development, and

pharmaceutical purification processes. In addition, last year she was team member of COHiTEC 2016, a training program in technology commercialization.

rfv17327@campus.fct.unl.ptRaquel Viveiros et al., Trends in Green chem, 3:2

DOI: 10.21767/2471-9889-C1-002