Volume 3, Issue 2 (Suppl)

Trends in Green chem

ISSN: 2471-9889

Environmental & Green Chemistry 2017

July 24-26, 2017

Page 72

5

th

International Conference on

6

th

International Conference on

July 24-26, 2017 Rome, Italy

Environmental Chemistry and Engineering

Green Chemistry and Technology

&

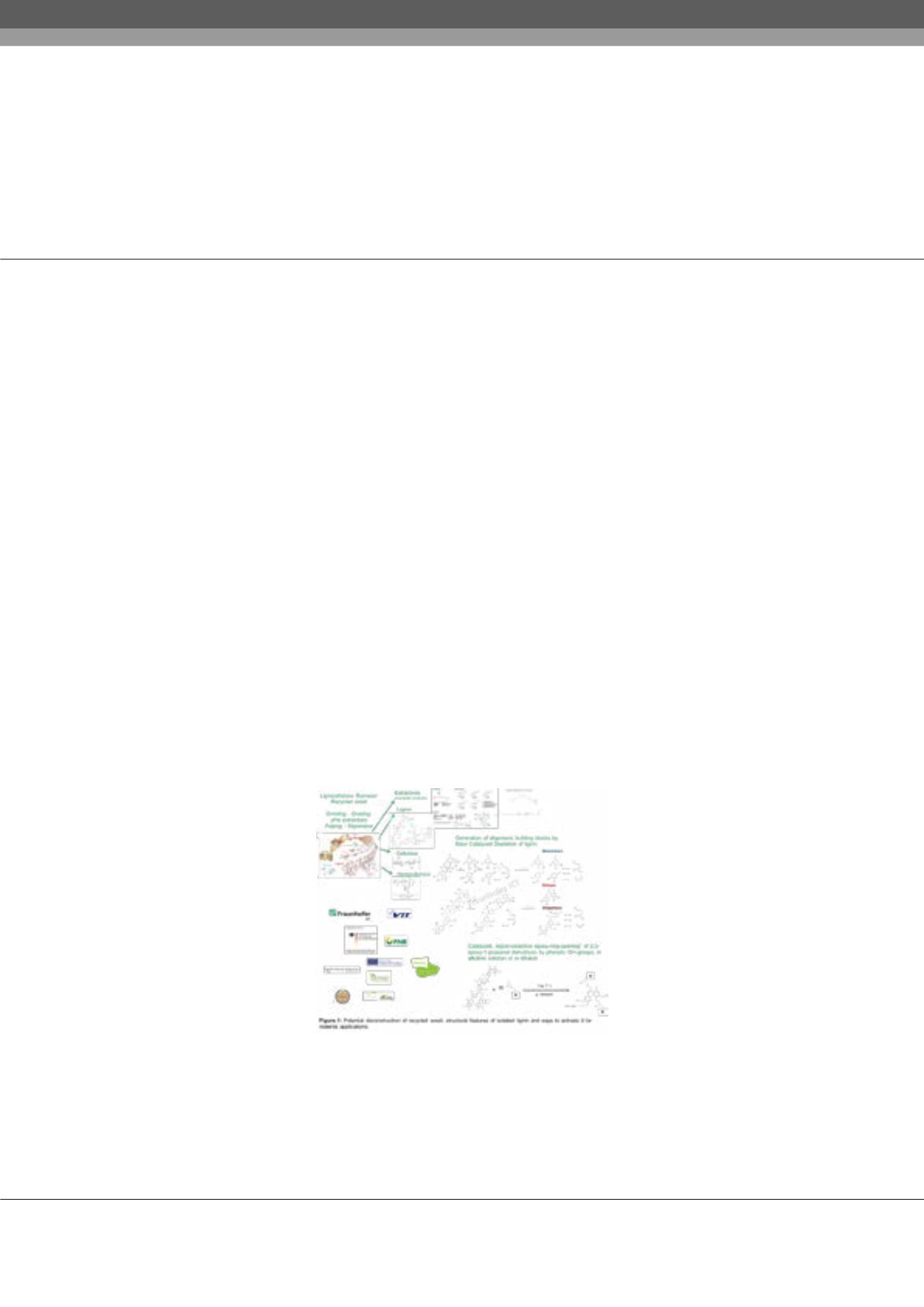

Potential deconstruction of recycled wood, structural features of isolated lignin and ways to activate it for

material applications

Detlef Schmiedl

1

, Jürgen Graf

1

, Beatrice Tübke

1

, Tiina Liitiä

2

, Anna-Stiina Jääskeläinen

2

and

Matti Siika-aho

2

1

Fraunhofer Institute for Chemical Technology, Germany

2

VTT Technical Research Center, Finland

Statement of the Problem:

With global rising use of wood & other lignocelluloses in the future, the importance of efficient

utilization of recycled wood (RW) will increase. Present utilization ways of RW-AI (natural wood, only processed mechanically,

German classification) are composites & combustion. Composition and availability of RW-AI offer a high potential for valorizing in

biorefineries to generate biogenic chemicals & fuels. The efficiency of present & future lignocellulose biorefineries can be increased

by valorizing of lignin.

Methodology:

A potential decomposition process of RW-AI is ethanol based E/W-OrganoSolv cooking to generate well hydrolysable

polysaccharides & Sulfur-free lignin. Depending on parameters, high quality lignin charges, differing in yield & features (MN, MW,

MW/MN, phenolic & aliphatic OH-groups) are available. It is evident, that valorizing of lignin in several material applications

strongly depends on present & on adjustable structural features by chemical modification. Such lignin activation steps are: grafting of

molecules, containing defined functional groups (e.g. 2, 3-epoxy-1-propanol & derivatives), onto the lignin-based molecule, as well

as catalyzed generation of oligomers, with accompanying elimination of steric hindrances & increase in phenolic OH-groups.

Findings:

Optimized auto- & acid-catalyzed E/W-OrganoSolv on RW-AI generate lignin yields of 50 to 70% respectively, in high

quality & charges differing in structural features. Base Catalyzed Depletion (BCD) of lignin in a continuously plug flow reactor, under

gentle to strong conditions, generate BCD-oligomers with yields of 90 to 40% respectively. Structural features of lignin & of oligomers

are adjustable. The addition reaction, “catalyzed, region-selective epoxy-ring-opening” of 2, 3-epoxy-1-propanol by phenolic OH-

groups, in alkaline solution or in ethanol is useful to increase the aliphatic OH number in lignin & BCD-Oligomers. Several catalysts

are available to use also green solvents, as reaction medium.

Conclusion:

Such lignin modification processes enlarge the scope of application as a result of changes involved in chemical & physical

characteristics.

Biography

Detlef Schmiedl, PhD, has his expertise in bioeconomy, lignocellulose biorefinery and chemical modification processes of macro molecules, like lignin, with the

target to develop and to illustrate process parameter effects on structural features, structure-function-relationships and catalyzed chemical modification path ways.

His passion is to develop environmental friendly, chemical processes according to the principles of green chemistry.

detlef.schmiedl@ict.fraunhofer.deDetlef Schmiedl et al., Trends in Green chem, 3:2

DOI: 10.21767/2471-9889-C1-002