Page 34

American Journal of Computer Science and Information Technology

ISSN: 2349-3917

E u r o s c i c o n C o n f e r e n c e o n

3D Printing and Wireless

Technology

S e p t e m b e r 1 7 - 1 8 , 2 0 1 8

L i s b o n , P o r t u g a l

Wireless and Printing Technology 2018

B

uildings made of additively manufactured (AM) components are likely

to have higher energy efficiency and environmental sustainability than

conventionally manufactured (CM) buildings. AM building components can

be highly customizable and produced with less material. Given the continued

development of AM and CM technologies, many markets and the use scenarios

of buildings that prioritize different performance criteria, building components

will likely be produced with a mix of AM and CM technologies for the foreseeable

future. However, since building professionals are not informed about the value

of AM through transparent metrics like cost and environmental impact they

are unable to make well-informed decisions about the application of AM in

the building sector. Case studies of two AM metallic building components, a

large window frame and a bracket, carried out by the authors in collaboration

with a global building façade contractor demonstrated that AM for building

components is technologically feasible and can lower environmental impact

by up to 87%, but is cost-prohibitive today; in some cases, the manufacturing

cost and schedule were about 90% higher and 91% longer respectively. Based on

the case studies, a 19 step assessment method was developed with the aim to

allow building professionals to rapidly and consistently assess the applicability

(A), schedule (S), environmental impact (E), and cost (C) of producing building

components with AM vs. CM. The formal, partially automated application of the

method showed that it reduces the effort required for the ASEC analyses by

97% and improves the consistency of the A, S, and C analyses. However, it did

not improve the consistency of the environmental impact (E) analysis due to the

inherent flexibility of the life cycle assessment (LCA) method standardized by

ISO14040. Future work includes fuller automation of the method and extension

of this approach to other industry sectors.

Biography

Natasa Mrazovic, M Arch Eng, MCE, completed her PhD at

the Civil and Environmental Engineering Department (CEE),

Stanford University with a focus on Sustainable Design and

Construction, specifically the implementation of additive

manufacturing technologies popularly known as 3D printing,

into the Architecture-Engineering-Construction industry.

The title of her thesis is Assessment Framework for Additive

Manufacturing Technologies in the AEC Industry. During her

PhD studies at Stanford, she was a Research Assistant at

the Center for Integrated Facility Engineering (CIFE) at CEE,

Stanford University, an affiliate in the Simulation Research

Group in the Environmental Energy Technologies Division

(EETD) at Lawrence Berkeley National Laboratory (LBNL),

US and a Visiting Doctoral Researcher at the Additive

Manufacturing and 3D Printing Research Group, University of

Nottingham, UK. In her 10-year long professional career as an

Architect, Chief Designer, and Project Manager, she worked on

large-scale projects in Eastern Europe and managed her own

architectural office.

natasam@stanford.edu natasa.mrazovic@gmail.comAssessment method for additive manufacturing in the

architecture engineering construction industry

Natasa Mrazovic and M Fischer

Stanford University, USA

Natasa Mrazovic et al., Am J Compt Sci Inform Technol 2018 Volume: 6

DOI: 10.21767/2349-3917-C2-005

Figure 1

: Observed problem: building professionals

are unable to make well-informed decisions about the

application of AM in their projects, because they are

not informed about the value of AM through transparent

metrics like cost and environmental impac

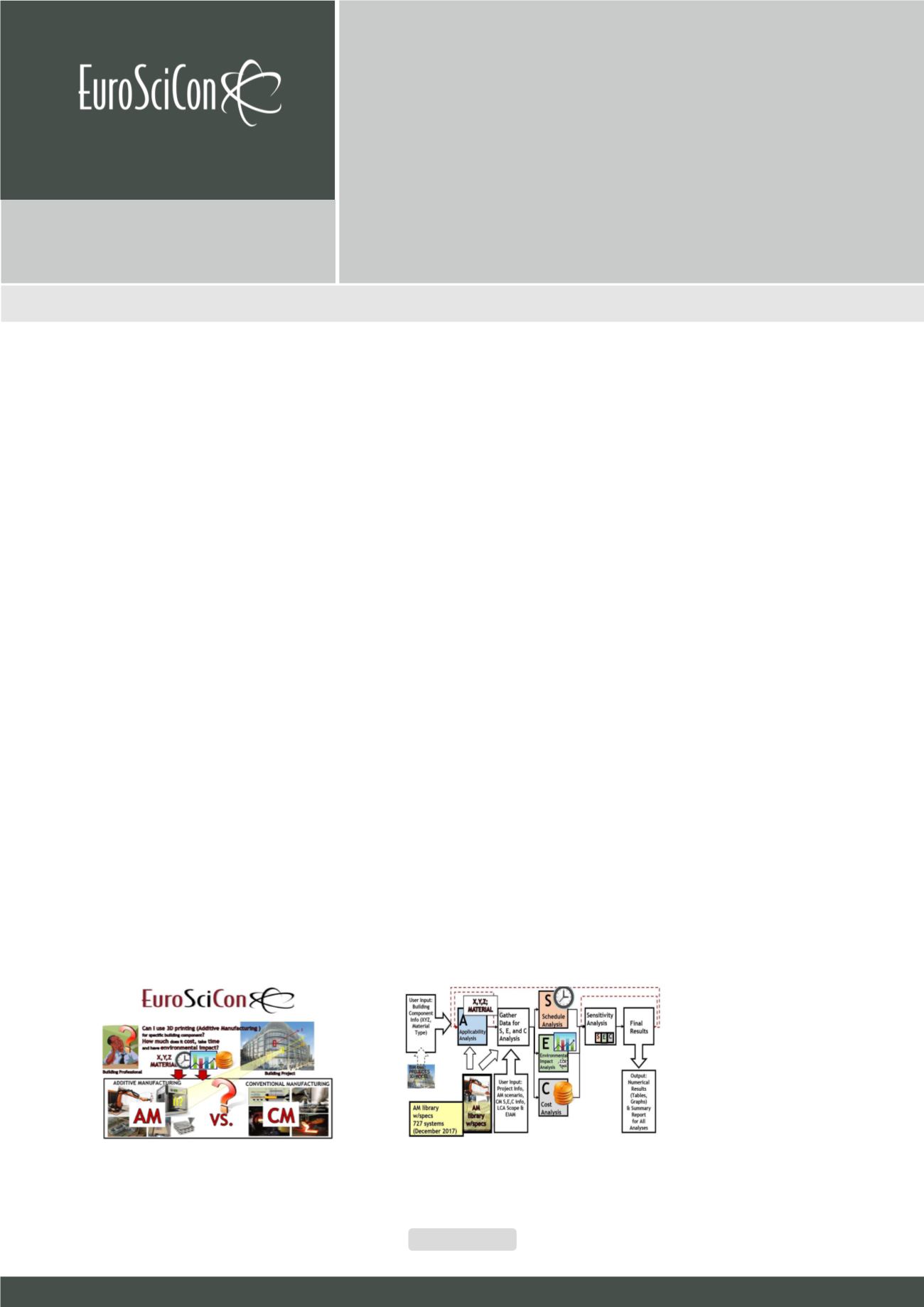

Figure 2

: High-level concept diagram of the workflow of

the assessment method.