Notes:

Volume 3, Issue 2 (Suppl)

Trends in Green chem

ISSN: 2471-9889

Environmental & Green Chemistry 2017

July 24-26, 2017

Page 53

5

th

International Conference on

6

th

International Conference on

July 24-26, 2017 Rome, Italy

Environmental Chemistry and Engineering

Green Chemistry and Technology

&

Graphene-based material for oil spill removal

Annalisa Pola

and

Alessandra de Folly d’Auris

Eni S.p.A, Italy

O

il spill events required efficient and rapid response by authorities and operating staff. The emergency management is not simple

and usually is affected by a large consumption of materials and high operative costs. The optimization of the adsorbents is a

starting point to reduce these costs. In this study, a graphene-based material (called Grafysorber®, produced by Directa Plus S.p.A)

was used inside adsorbent devices (barriers and pillows) to treat waters containing an oily separated phase. Grafysorber® is a super-

expanded graphite with a production apparent density of about 2.5 g/L. Three different kind of oils were tested: kerosene, diesel fuel

and crude oil, to understand if there is a relationship between viscosity and sorption capacity. In addition, reusability of each device

was evaluated. Little pillows of about 10*10 cm were used for adsorption tests. Results showed that the greater is the viscosity, the

greater is the amount of oil sorbed; 50.8 g/g for kerosene, 76.5 g/g for diesel fuel, 81.78 g/g for crude oil. Grafysorber® pillows can be

reused, after simple squeezing, for about 4-5 times. A progressive decrease of adsorption capacity was detected. Polypropylene, the

standard adsorbent material used worldwide in case of water oil spill clean-up activities, showed a sorption capacity at least six times

lower than Grafysorber®. The effect of the waves was considered, using diesel fuel, in a 1*5 meters tank, and small adsorbent barriers

(7.5 cm diameter and 50 cm length). Water motion caused an increase in the saturation’s speed but also an increase of retained water

both for Grafysorber® and for Polypropylene barriers. A dropping phase of 5 min is necessary for Grafysorber® and polypropylene

devices to favor the water expulsion from the adsorbent device. Anyway, it has been demonstrated that Grafysorber® retains on

average the 50% less of water than polypropylene.

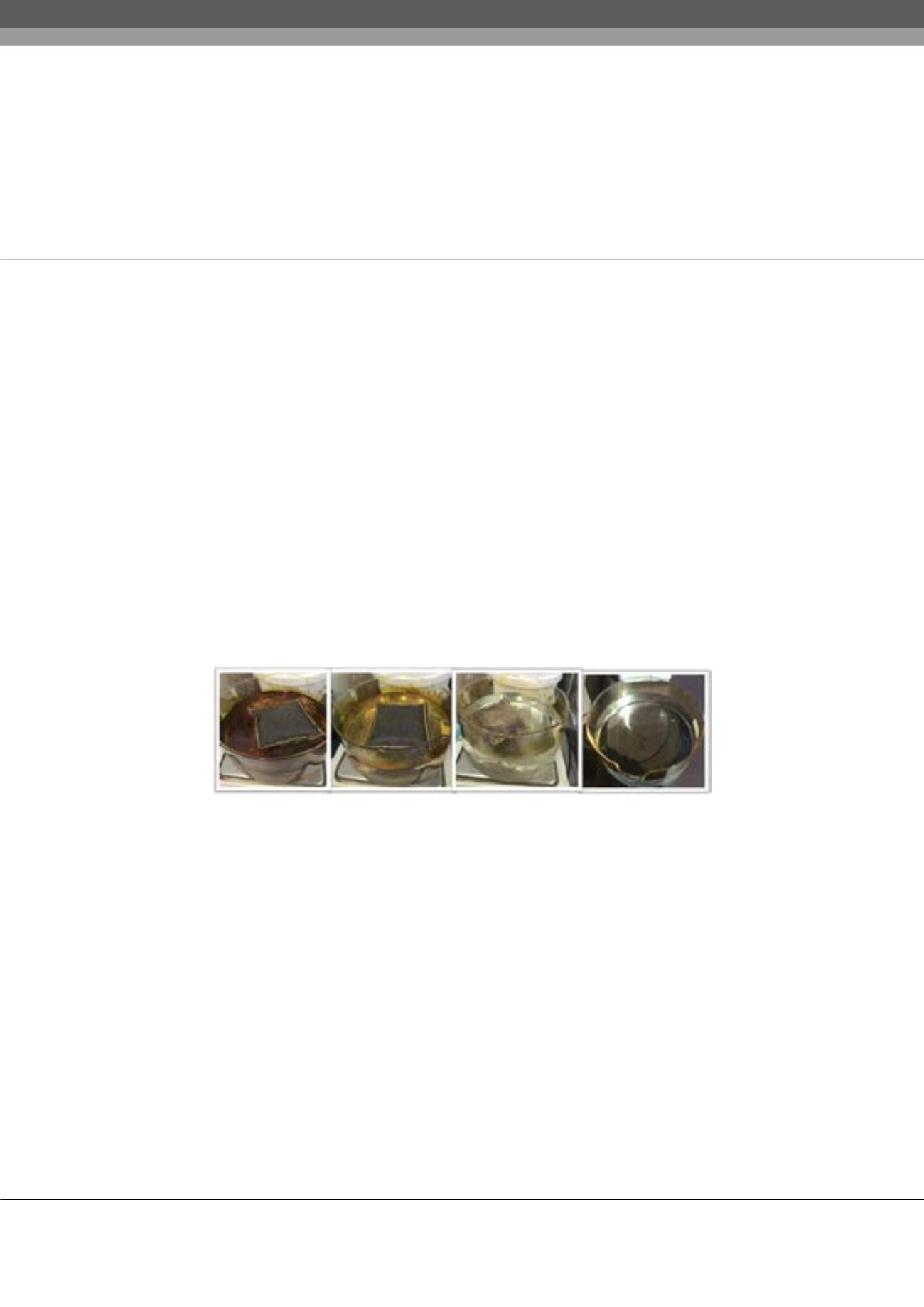

Figure 1:

Example of crude oil adsorption by Grafysorber G+

Biography

Annalisa Pola graduated in Environmental Science (University of Insubria – Como – Italy) and is an Environmental Application Manager at Directa Plus S.p.A.

Directa Plus is one of the largest producers and suppliers of graphene-based products for use in consumer and industrial markets worldwide.

annalisa.pola@directa-plus.comAnnalisa Pola et al., Trends in Green chem, 3:2

DOI: 10.21767/2471-9889-C1-002