Structural Chemistry & Crystallography Communication

ISSN: 2470-9905

June 04-05, 2018

London, UK

Crystallography 2018

Page 14

3

rd

Edition of International Conference on

Advanced Spectroscopy,

Crystallography and Applications

in Modern Chemistry

P

roperties of materials are governed by their microstructures,

which in turn are controlled by the phase transformations

at a given composition. To obtain the desired microstructure,

it is essential to understand the phase transformations that

occur in the material. Crystallography of phase transformations

defines the morphology of microstructures, explains the actual

phase transformation process at an atomic level and describes

the relationship between the new phase and the parent phase.

Hence, the crystallography controls the final properties of

materials. In the past decades, although a number of theories/

models have been developed to understand the crystallography

of phase transformations, none of them can be used to design

new materials and processes until the edge-to-edge matching

(E2EM) model became available [1]. Development of the E2EM

model was based on the principles that the nature of a coherent

or semi-coherent interface and the associated crystallographic

relationships are governed by minimisation of interfacial energy

between two crystals; and that the necessary and sufficient

condition forminimisationof the interfacial energy is tomaximize

the atom matching. The best and most effective approach to

achieve the maximum atom matching is the matching of atom

rows that are close packed or nearly close packed and are

contained in the matching planes that are arranged to meet in

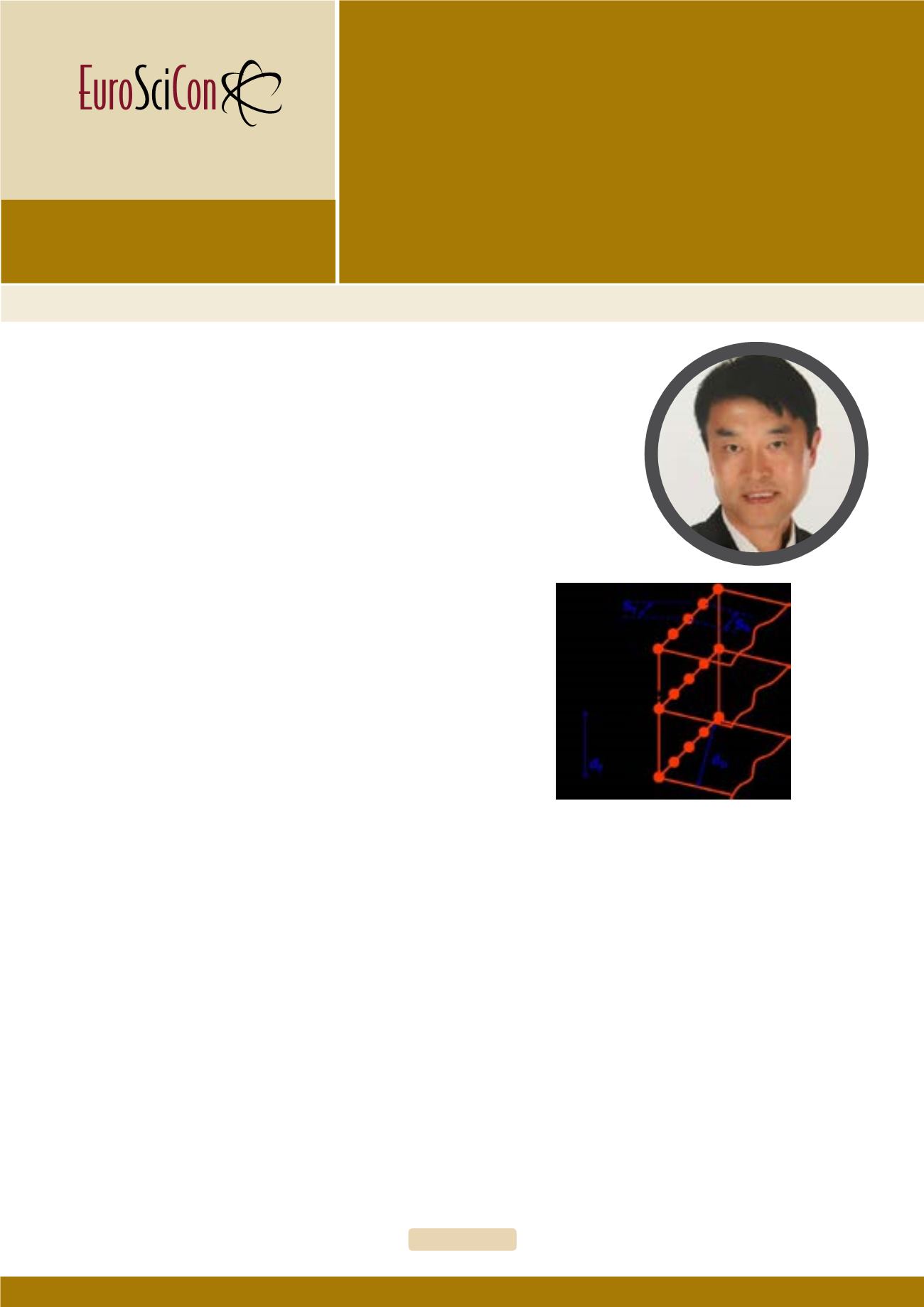

the “edge to edge” manner as shown in following figure.Major

advantage of the E2EM model over all other previous models

is its predictive capacity from the first principle. Thus, it can be

used to design new alloys and processes. In this presentation,

after briefly reviewing the success of this model in predictions

of the crystallographic features of diffusion controlled phase

transformations in solids [1], its applications in development

of new and more effective grain refiners for cast metals,

including magnesium alloys [2], zinc alloys [3] and steels [4], are

introduced. Predictions of the textures and growth features of

epitaxial growth and crystalline nanowires [5] are also presented.

Figure:

Schematic illustration of the edge-to-edge matching model

Recent Publications

1. Zhang M-X, Kelly P (2014) Crystallographic features of

phase transformations in solids Progress in Materials

Science, 54:1101-1170.

2. Ali Y, Qiu D, Jiang B, Pan F-S, Zhang M-X (2016) The

influence of CaO addition on grain refinement of cast

magnesium alloys Scripta Materialia, 114:103-107.

3. Liu Z-L, Qiu D, Wang F, Taylor J, Zhang M-X (2015)

Crystallography of grain refinement in cast zinc-copper

alloys. Journal of Applied Crystallography 48:890-900.

4. Li M, Li J, Qiu D, Zheng Q, Wang G, Zhang M-X (2016)

Crystallographic study of grain refinement in low

and medium carbon steels. Philosophical Magazine

96:1556-1578.

5. Liu Z, Zhang Z, Jiang R, Li X, Zhang M-X, Qiu D (2016)

Crystallography of phase transformation in the self-

inclined InAs nanowires grown on GaAs{111} Scripta

Materialia, 121:79-83.

CRYSTALLOGRAPHY OF PHASE TRANSFORMATIONS IN

SOLIDS AND ITS APPLICATIONS

Mingxing Zhang

The University of Queensland, Australia

Mingxing Zhang, Struct Chem Crystallogr Commun 2018, Volume 4

DOI: 10.21767/2470-9905-C1-004