Smart Materials Congress 2019

Nano Research and Applications

ISSN: 2471-9838

Page 23

August 01-02, 2019

Dublin, Ireland

Smart Materials and

Structures

8

th

International Conference on

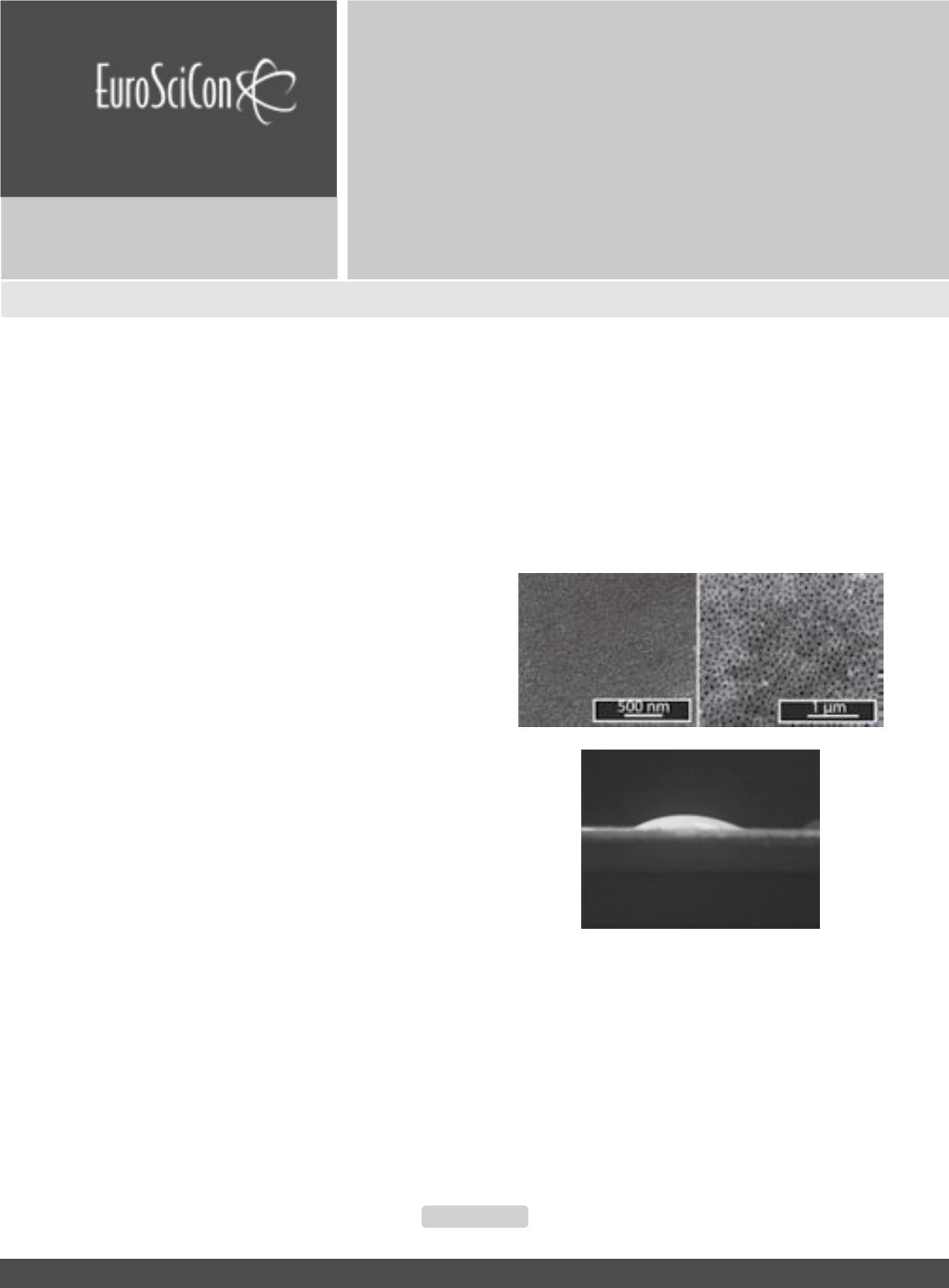

Influence of chemical and electrochemical surface

treatment of ECAP titanium on resulting corrosion

properties and wettability

Katerina Dedkova

1

, Josef Hlinka

1

, Ludek Dluhos

2

and

Kristina Cabanova

1

1

VSB-Technical University of Ostrava, Czech Republic

2

Timplant, s.r.o.,Czech Republic

E

CAP titanium of lower grades with extra fine grains

may be used for manufacturing of highly loaded

implant or their parts and presents excelent replacement

of strandartly used Ti-6Al-4V alloy. This type of material

aslo showes excelent corrosion properties ang high

level of biocompatibility, which can be even impoved

by different surface treatment. This paper deals with

possibility oxidic anodization as a method of creation

highly organised nanostructures on implant surface and

further chemical treatment of anodized layer in acid/

alkaline solutions. It was proved that chemical treatment

increases content of specific ions in anodized structure,

which will leads into more effective osteointegration

process while not affecting its of corrosion properties,

which was tested by potentiodynamic polarization

methods in artificial isotonic physiological solution

according ASTM standards for implants. On the other

hand chemical treatment positively affects wettabilility

resp. surface energy of studied samples. Many previous

studies focused on osteointegration process confirmed

that lower values of contact angle directly corelate with

effectivity of ossteointegration process and a relation

between preferred induced type of organic tissue and

implants surface energy has been previously published.

Presented procedures of surface treatments shows

promising results and might find its use in commertial

implants manufacturing.

Biography

Katerina Dedkova has completed her PhD from VSB-Techni-

cal University of Ostrava. She is the Researcher at Center of

Advanced Innovative Technollogies. She has published more

than 14 papers in reputed journals and has been serving as a

Rewiever of repute journals. Her research interest include bio-

compatible materials and nanocomposite materials.

katerina.dedkova@vsb.czKaterina Dedkova et al., Nano Res Appl 2019, Volume 05