Smart Materials Congress 2019

Nano Research and Applications

ISSN: 2471-9838

Page 30

August 01-02, 2019

Dublin, Ireland

Smart Materials and

Structures

8

th

International Conference on

Konatsu Kamimoto, Nano Res Appl 2019, Volume 05

Rapid sintering of unique material of LNT (Li

2

O-Nb

2

O

5

-TiO

2

)

with periodical structure by air pressure control

Konatsu Kamimoto

Toyohashi University of Technology, Japan

I

n the Li

2

O-Nb

2

O

5

-TiO

2

system, Li

1+x−y

Nb

1−x−3y

Ti

x+4y

O

3

(0.05

≤ x≤0.3, 0≤y≤ 0.182) (LNT) forms with a superstructure

known as the M-phase, which is formed by the periodical

insertion of an intergrowth layer in a matrix with a

trigonal structure. To apply this unique structure as a

host material of phosphor, new phosphors have been

investigated based on LNT or related structures made by

a conventional electric furnace. However, the synthesis

of a homogeneous M-phase required treatment at 1373

K for over 24 h. The sintering time depended on the Ti

content, and annealing was repeated in an electric

furnace for 24–264 h until a homogeneous structure was

formed by the insertion of periodical intergrowth layers.

Accordingly, a fast sintering technique that uses lower

energy is required for the practical application of this

material as phosphors and electro ceramics. This time,

we pioneered a new rapid sintering technique, which

uses a simpler furnace that only requires the control of

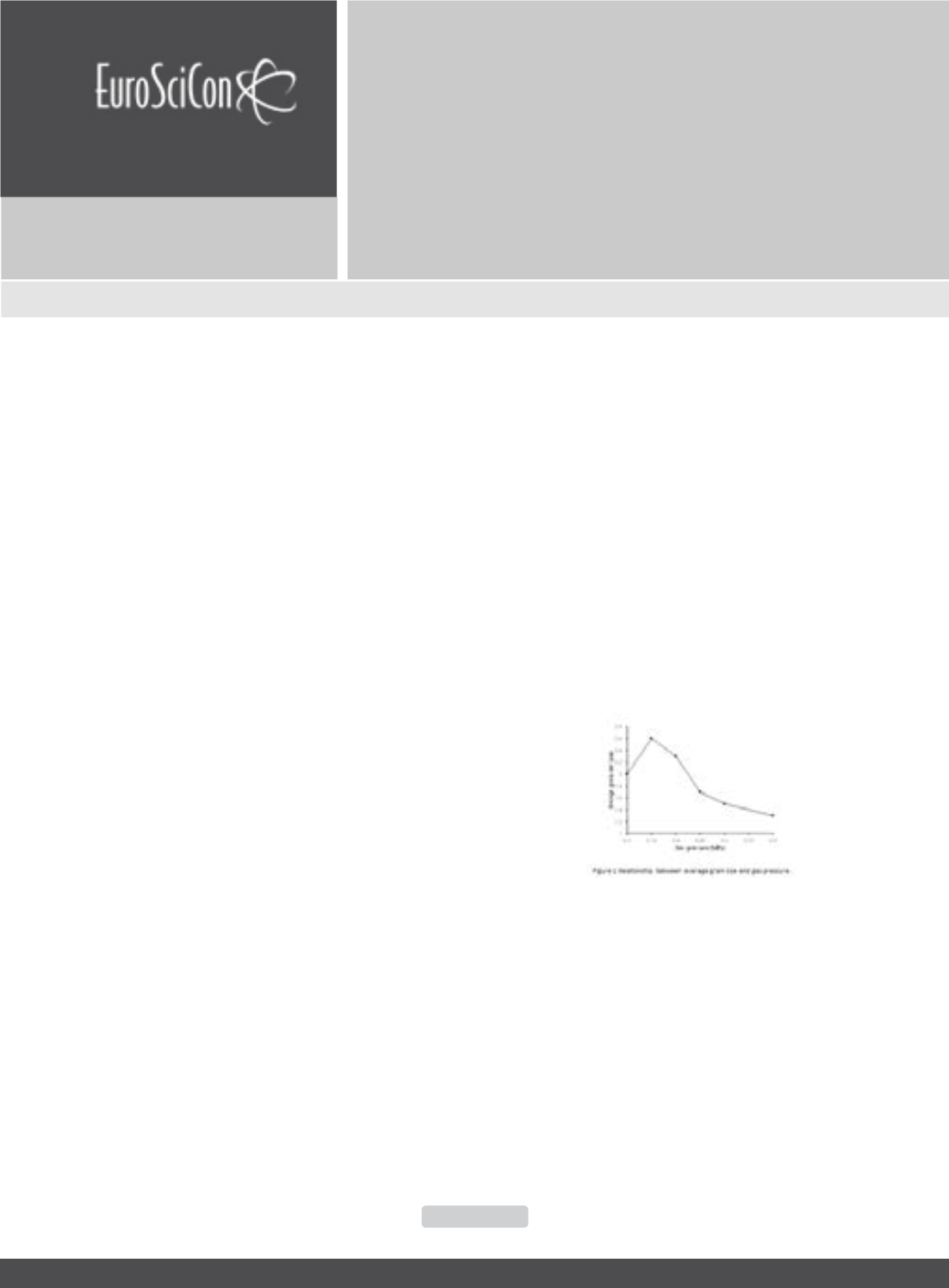

air pressure. The LNT solid solutionmaterial, with various

Ti content of 15-30 mol%, was sintered at 1273 K-1373

K for 30 min-1 h under various air pressures (0.35 MPa–

0.60 MPa) using the newly developed an air-pressure

control atmosphere furnace (FULL-TECH FURNACE

CO., Ltd., Osaka, Japan). To clarify the mechanism of

the rapid sintering, various microscales to nanoscale

characterization techniques were used: X-ray diffraction,

a scanning electron microscope, a transmission

electron microscope (TEM), a Cs-corrected scanning

TEM equipped with electron energy-loss spectroscopy

and X-ray absorption ne structure spectroscopy. As a

result, the biggest grain of LNT with Ti 20 mol% could be

synthesized at 1373 K for 30 min under 0.35 MPa. It was

confirmed that a homogeneous phasewas obtained from

the TEM image and selected area electron diffraction

(SAED) patterns from the [010] axis. We concluded that

through the control of air pressure, the interstitial oxygen

enabled rapid sintering with a combination of vacancies,

and that accordingly, grain growth and the distribution of

Ti ions improved somewhat surprisingly.

Recent Publications

1. H Nakano, K Kamimoto, T Yamamoto and Y

Furuta (2018) Rapid sintering of Li

2

O-Nb

2

O

5

-

TiO

2

solid solution by air pressure control

and clarification of its mechanism. Materials

11(6):987.

2. H Nakano, K Kamimoto, N Yokoyama and K

Fukuda (2017) The effect of heat treatment

on the emission color of P-doped Ca

2

SiO

4

phosphor. Materials 10(9):1000.