Smart Materials Congress 2019

Nano Research and Applications

ISSN: 2471-9838

Page 36

August 01-02, 2019

Dublin, Ireland

Smart Materials and

Structures

8

th

International Conference on

Sonia Norouzi Esfahany et al., Nano Res Appl 2019, Volume 05

Tunning switch temperature of shape memory

polyacrylamide hydrogel

Sonia Norouzi Esfahany, Mehrdad Kokabi

and

Ghazaleh Alamdarnejad

Tarbiat Modares University, Iran

I

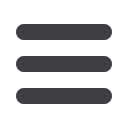

n this work, chemically cross-linked polyacrylamide

(PAAm) hydrogel prepared by free radical polymeriztion.

Theeffectofwatercontentonglasstarnsitiontemperature

(Tg) of hydrogel, as switch temperature of shapememory

system, was investigated using dynamic mechanical

analysis (DMA). The transition temperature, i.e. the

desired switch temperature for our work, was chosen

around ~ 30

o

C by tunning thewater content of hydrogel at

25%, Fig. 1. Shapememory behaviour of chosen hydrogel

was investigated for a full cycle, i.e. four steps, by DMA.

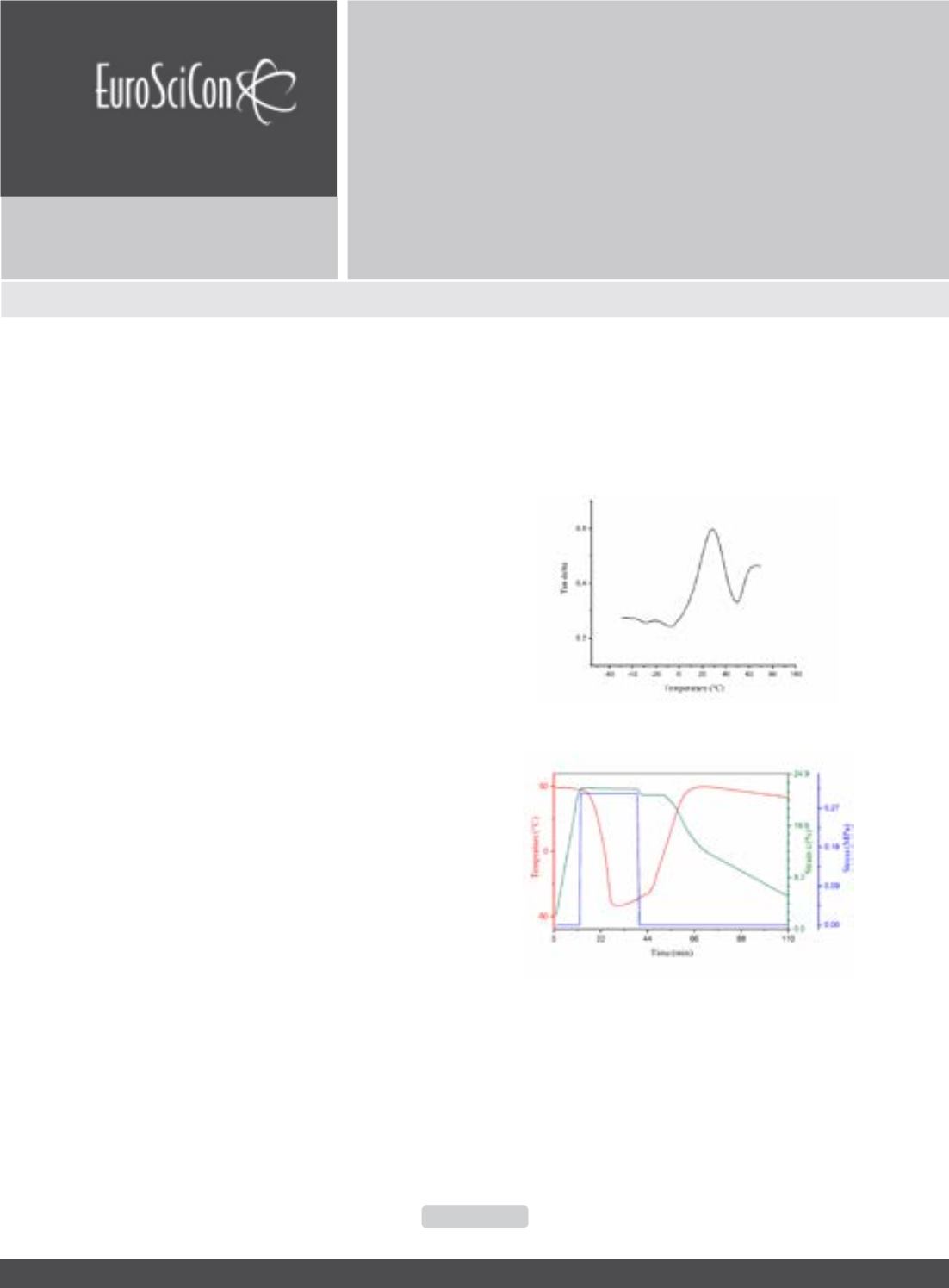

The four steps procedure performed at a constant

heating/cooling rate of 5

o

C.min-1. First, the sample

was heated to 50

o

C (above the switch temperature) and

stretched to a certain strain (ε) under a constant force

(Step 1). Then, the deformed sample was cooled to -50

o

C

under the fixed force (Step 2). The force then removed

and the temporary strain was measured (Step 3). Finally,

the sample was reheated to 50

o

C and kept for 50 min in

this temperature, then the recovery strain recorded (Step

4). The shape fixing ratio and shape recovery ratio as the

main characteristics of shape memory polymeric system

calculated from Fig. 2. The results indicated that the

shape fixing ratio and shape recovery ratio of the system

were 96% and 78%, respectively. Recovering to orginal

shape was started around 10

o

C. The sample showed

good shape fixity because of existence the hydrogen

bonds between PAAm and water. Hydrogen bonds as

physical cross linkers could improve structural strength

of the sample.

Biography

Miss S. Norouzi Esfahany has just completed her MSc from

Tarbiat Modares University. This article is a portion of her MSc

thesis.

Snes.69@gmail.comFig 1. DMA curve PAAmwith 25% water.

Fig 2. Shape memory behavior of PAAm

with 25% water.