ISSN : 2575-7725

Journal of Stem Cell Biology and Transplantation

Taste Masking: A Unique Approach for Bitter Drugs

Chauhan R*

Zernike Institute for Advanced Materials, University of Groningen Nijenborgh 4 NL - 9747 AG Groningen, The Netherlands

- *Corresponding Author:

- Chauhan R

Molecular Dynamics & Theoretical Chemistry

The Netherlands.

Tel: +31 6+8249703

E-mail: rohit03.chauhan@gmail.com

Received date: June 29, 2017; Accepted date: July 03, 2017; Published date: July 08, 2017

Citation: Chauhan R (2017) Taste Masking: A Unique Approach for Bitter Drugs. J. stem cell Bio. transplant. Vol. 1 No. 2:12

DOI: 10.21767/2575-7725.100012

Abstract

Taste is the maximum valuable factor within the ca Taste is the maximum valuable factor within the case of orally drugs administering. Flavor covering is a prerequisite for bitter tablets to better the patient compliance, particularly in the paediatrics and geriatric population. The hassle of the sour taste of drug in pediatric formulations is a completely huge task to the formulators on this gift time. Overlaying is an effective device for the development of the sour taste of medication of patient compliance which sooner or later comes to a decision the commercial achievement of the product. In recent times, two maximum usually software are utilized to conquer the horrific flavor of the drug. The primary software consists of reduction of drug solubility within the saliva and second to modify the potential of the drug to interact with taste receptor. At present various methods are available in the market to masks the unwanted taste of the drugs. Some of them are the mass extrusion strategies and ion trade resins, molecular complexes of drugs with other chemical substances, coating of drug debris, melting method, micro encapsulation by using a formation of inclusion complexes, stable dispersions, prodrugs. USe of orally drugs administering: Flavor covering is a prerequisite for bitter tablets to better the patient compliance, particularly in the paediatrics and geriatric population. The hassle of the sour taste of drug in pediatric formulations is a completely huge task to the formulators on this gift time. Overlaying is an effective device for the development of the sour taste of medication of patient compliance which sooner or later comes to a decision the commercial achievement of the product. In recent times, two maximum usually software are utilized to conquer the horrific flavour of the drug. The primary software consists of reduction of drug solubility within the saliva and second to modify the potential of the drug to interact with taste receptor. At present various methods are available in the market to masks the unwanted taste of the drugs. Some of them are the mass extrusion strategies and ion trade resins, molecular complexes of drugs with other chemical substances, coating of drug debris, melting method, micro-encapsulation by using a formation of inclusion complexes, stable dispersions, prodrugs

Keywords

Drugs; Receptor; Coating; Administration

Introduction

It’s right, flavor is the most crucial component which note affected person compliance. However, flavor is maximum severe system issues which might be encountered with sure pills. In particular for folks that are pediatric patients. Oral administration of sour capsules with an appropriate diploma of palatability is trouble for health care carriers. Numerous oral pharmaceuticals have now not good sour-tasting components. Any pharmaceutical formula with a great taste would actually be a competitor’s product and might be into higher compliance and healing price for the patient and can be greater commercial enterprise and income for the enterprise.

The Experience of Flavor

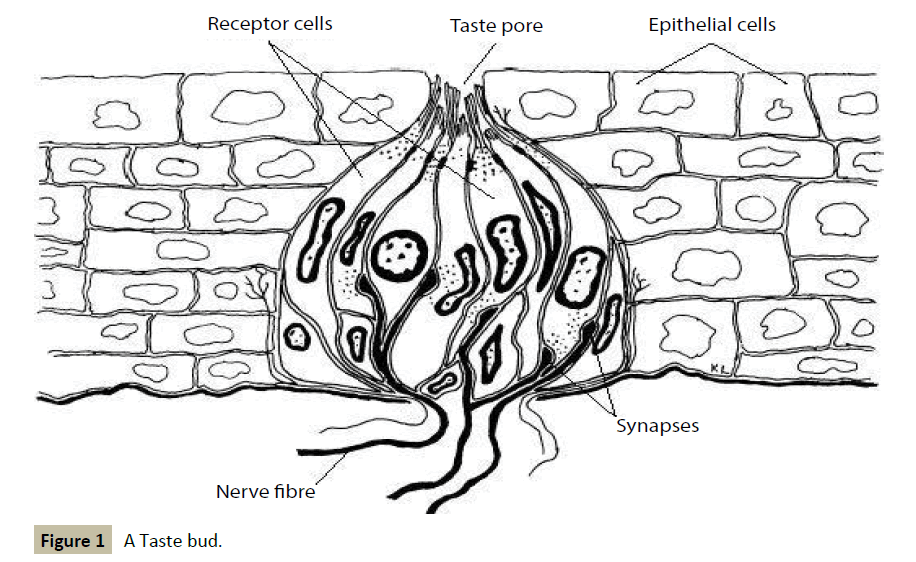

Meaning of the flavor is the potential to dissolved molecules and ions to the body. Human detects taste with flavor receptor cells which are onionâ€ÂÂformed organs known as flavor buds. Every flavor bud has a pore that opens out to surface of the tongue allowing molecules and ions taken into the mouth to attain the receptor cells interior (Figure 1).

Human has almost 10,000 flavor buds which seem inside the fetus at about three months earlier than the birth [1-5]. A single taste bud must be containing 50â€ÂÂ100 taste cells. Each taste cells have receptors on its apical floor. These are transmembrane proteins which bind to the molecules and ions and provide rise to the four exclusive number of flavor sensations specifically †sour, sweet, bitter and salty (Table 1).

Table 1: Specific area of tongue and threshold concentration for primary taste sensations.

| Taste Concentration | Area of tongue | Threshold |

|---|---|---|

| Sweet (sucrose) | Tip of tongue | 0.5% |

| Salt (NaCl) | Tip of sides of tongue | 0.25% |

| Sour(HCl) | Sides of tongue | 0.007% |

| Bitter(avinine) | Back of tongue | 0.00005% |

A fifth simple flavor umami has been discovered lately. Umami flavor is a positive type of amino acids (e.g., monosodium glutamate). There is additionally integration among the chemical shape of a compound and its flavor. High molecular weight salts as bitterness and low molecular weight as a salty. Nitrogen compounds containing, together with alkaloids, become sour in taste and also organic compounds containing including hydroxyl organizations turn out to be exceedingly candy as numbers of OH group increase.

Maximum usually techniques are worried for achieving taste masking include distinct chemical and physical strategies that save you the interplay of drug substance with flavor buds. The very best method involves use of flavor enhancers specialdifferent techniques diagnosed for flavor covering which encompass inclusion complicated formation with cyclodextrin, use of ion alternate resins, and use of anesthetic sellers, solubility limiting strategies, liposome, multiple emulsions, and polymer coating and so on. First-class and properly taste covering method and method ought to have the subsequent residences [6].

1) Involvement of least range of equipments and processing steps.

2) Minimal quantity of excipients for most excellent components.

3) No unfavourable harm on drug bioavailability.

4) Economical and without difficulty available excipients require.

5) Low production value.

6) Completed at room temperature.

7) Excipients which have excessive margin of safety.

8) Rapid and easy to prepare.

Elements which are required into consideration throughout the tastecovering formulation procedure include:

1) Extent o f the sour taste of the active pharmaceutical component [7]

2) Dose shape

3) Distribution form and length of drug particulate

4) Solubility and ionic traits of drug

5) Disintegration and dissolution fee of the finished product

6) Correct launch profile

7) Accurate bioavailability

8) Dosage load

Taste Masking Strategies

Flavor masking with sweeteners and flavors

Artificial flavors: Alcoholic solutions, aqueous solutions and powders

Natural vs. Synthetic

• Cheaper

• More readily available

• Less variable in chemical composition more stable

Basis of Choosing a Flavor: Complementary to present flavor of the drug regarded popularity of particular flavors. Age of sufferers hypersensitive reaction (Table 2) [8].

Table 2: Flavours herbal flavours.

| Juice | Raspberry |

|---|---|

| Extracts | Liquorices |

| Spirits | Lemon and Orange |

| Syrups | Blackcurrant |

| Tinctures | Ginger |

| Aromatic waters | Anise and cinnamon |

| Aromatic oils | Peppermint and Lemon |

Flavoring agents for taste masking

Sweetners

• Supplement flavors associated with sweetness.

• Soothing effect on the membranes of the throat.

Natural Sweetener: Sucrose, glucose, fructose Sorbitol, mannitol, glycerol, Honey, liquorice (Table 3).

Table 3: Flavouring agents for taste masking.

| Basic Taste | Masking Agents |

|---|---|

| Salt | Butterscotch, maple, apricot, peach, vanilla, winter green mint. |

| Bitter | Wild cherry, walnut, chocolate, mint, anise |

| Sweet | Vanilla, fruit and berry |

| Sour | Citrus flavor, licorice, root beer, raspberry |

Artificial sweetener: Saccharin, Saccharin sodium, Aspartame.

Nutritive: Sucrose, Fructose and Glucose.

Polyols: Mannitol, Sorbitol, Xylitol, Erythritol, Maltitol.

Non-Nutritive: Aspartame, sucralose, neotame and saccharine.

Novel sweeteners: Trehalose, Tagatose.

List of FDA (The food and drug administration) approved Non- Nutritive Sweeteners (Sweetness factor, Sucrose=1) (Table 4).

Table 4: List of FDA (The Food and Drug Administration) approved Non-Nutritive Sweeteners.

| Sr. No | Sweetener | Sweetness factor |

|---|---|---|

| 1 | Aspartem | 180-200 |

| 2 | Sucralose | 600 |

| 3 | Acesulfame K | 200 |

| 4 | Neotame | 7000-13000 |

| 5 | Saccharin | 300 |

Taste protecting by way of granulation

Granulation is most reasonably-priced, fast operation and a without difficulty taste masking technology. This step can be doing for taste masking of slightly bitter tasting drug. Granulation lowers the floor area of the bitter substance that comes in touch with the tongue upon oral intake. Low melting factor waxes and liquids are hydrogenated castor oil, glycerol palmitostearate and glyceryl behenate are typically used substances at some stage in the granulation to acquire flavor masking [9].

Flavour masking via microencapsulation

Microencapsulation is a process wherein very tiny droplets, particles of liquid and stable fabric are coated with a film or polymeric fabric. Coating is a commonly time useful method for a number of packages in pharmaceutical enterprise utility. But it is used as generally for manufacturing of sustained release, Gastrointestinal dosage bureaucracy; it also has essential applications in covering the unsightly taste. It’s miles maximum critical to understand the truth that simplest soluble part of the drug can generate the sensation of flavour. Coating the active drug with a selected polymer movie can reduce its solubility in saliva and taste might be masked. Coating of drug debris which creates a bodily barrier among the drug and the flavour buds and flavour of lively will be masked [10].

The goal of Microencapsulation can be based on any of the subsequent strategies.

1) Air suspension coating

2) Coacervatio: section separation

3) Spray drying and spray congealing

4) Solvent evaporation

5) Multiorifice - centrifugal mann

6) Pan coating

7) Interfacial polymerization

Polymers used for coating in microencapsulation

Coating is normally useful method inside the pharmaceutical enterprise. It’s far based totally at the kind of coating cloth, coating solvent machine, and the variety of coating layers by way of deciding on the proper type of coating cloth it's miles possible to masks the taste of a bitter drug, at the same time as on the identical time, not adversely affecting the drug release profile [11]. Polymers were completely used as coating substances, both single or in combination, as a single or multi-layer coating, within the taste masking of bitter capsules. combinations of pH impartial water insoluble polymers inclusive of cellulose ethers, cellulose ester, polyvinyl acetate and H2O soluble polymers together with cellulose acetate butyrate, polyvinylpyrollidone, hydroxyethyl cellulose were used to gain a balance between the flavor covering and in vitro launch [12].

Hydrophobic polymers have been exclusively used for coating bitter tablets to obtain taste overlaying. This coating work as physical barriers over the drug debris as a consequence, hydrophilic polymers can also provide taste covering of Ibuprofen, through coating with hydrophilic polymers together with hydroxyethyl cellulose or a combination of hydroxyethyl cellulose and hydroxypropyl methylcellulose. Sweeteners can be protected inside the coating solution for a higher flavor overlaying overall performance. One of the only techniques of drug particle coating is the fluidized mattress processor. On this method powder as first-rate as 50m, are fluidized in growth chamber with the aid of heated, high speed air and the drug particles are covered with a coating answer brought commonly from the pinnacle as spray through nozzle. The lined granules are dried with warm air [13].

Ion exchange resins

Ion exchange resins (IER) have received vast interest from pharmaceutical scientists because of their versatile residences as drug transport vehicles. In beyond few years, IER had been substantially studied within the development of Novel drug shipping machine and different biomedical packages. Several ion trade resin merchandise for oral management had been developed for fast launch and sustained release functions [14]. Sour tasting capsules can be absorbed onto ion exchange resins, consequently effectively disposing of them from solution at some point of the transit through the mouth, at salivary pH 6.8, remains in intact shape making the drug unavailable for the taste sensation. Various researchers have found out that ion exchange resins are similarly suitable for drug delivery technology. Some ion exchange resins used extensively for flavor protecting motive in industries are Amberlite IRP64, Amberlite IRP69, Indion 204, Indion 214, Kyron T-114 and Kyron T-104.

Taste Protecting Via Components of Inclusion Complexes

Inclusion complexation is a system in which the guest molecule is included in the hollow space of a bunch or complexing agent. The complexing agent is capable of covering sour taste of drug by using both reducing its oral solubility on ingestion or decreasing the amount of drug particles uncovered to taste buds. Cyclodextrin is most broadly used complexing agent for inclusion type complexes. It is candy, nontoxic, cyclic oligosaccharide acquired from starch the following are the examples of drugs that the bitter taste may be suppressed by making inclusion complexes [15].

Taste Masking by Means of Prodrug Technique

Chemical modification, which includes prodrug design, is a powerful method for reducing solubility, and thereby improving taste. A prodrug is chemically changed inert drug precursor which upon biotransformation liberates the pharmaceutically energetic determine compound. Bitterness of a molecule can be due to the efficiency of the flavor receptor substrate adsorption response, that's associated with the molecular geometry of the substrate [16]. If alteration of the discern molecule occurs through spinoff formation, the geometry is altered, affecting the adsorption regular. Consequently the magnitude of a sour flavor reaction or taste receptor-substrate adsorption steady can be changed via changing the molecular configuration of the parent molecule. The extremely sour antibiotics had been the focal point of lots work in reversible drug amendment. Flavor overlaying of drug via Prodrug method is given in Table 5.

Table 5: Taste masking of drug by Prodrug approach.

| Parent Drug | Pro-Drug with improved taste |

|---|---|

| Clindamycin | Alkyl ester |

| Chloramphenicol | Palmitate or phosphate ester |

| Erythromycin | Alkyl ester |

| Lincomycin | Phosphate or alkyl ester 3,4,5- Trimethoxy benzoate |

| Tetracyclin | Salts |

Strong Dispersion Device

Solid dispersion has been defined as dispersion of one or extra lively ingredients in an inert provider or matrix at solid kingdom prepared with the aid of melting (fusion) solvent or melting solvent method. Lately strong dispersions had been brought as a flavor masking technology. Tsau and Damani (1994) disclosed a drug-polymer matrix composition to achieve the flavor covering of dimenhydrinate [16]. Amine or amido group of dimenhydrinate may have a physical and chemical interaction with the carboxylic acid and esters agencies of copolymers including shellac, zein and cellulose acetate phthalate hydrophobic polymers and lengthy chain fatty acids have been used to attain the taste overlaying with the aid of solid dispersion. This approach generally requires a better awareness of excipients as compared to other flavor protecting strategies. Natural polymers which include shellac and zein, and enteric polymers like derivatives of acrylic acid polymers and phthalate are appropriate choices to broaden the taste masked stable dispersions [17].

pH Modifiers

Many natural and synthetic polymers, resins and waxes alone or in aggregate were hired for taste overlaying. The enteric polymers like eudragit L are used for taste masking but the pH of saliva is near 5.8 and those polymers solubilize at pH beyond 5.5 so there's an opportunity of drug being in part leached therefore there may be a need for the development of flavor overlaying polymer such that the sour taste is absolutely masked by way of the polymer on the pH of saliva in mouth and inside the reconstitution medium as in case of the liquid orals and further which is able to defend the drug in a biologically lively shape, from the moisture in the dosage shape and liberating the drug swiftly in the stomach without affecting its absorption and bioavailability [18,19].

Taste covering by way of adsorption

Adsorbates are generally used in flavor covering technologies. Adsorbate of bitter tasting drug can be taken into consideration because the less saliva soluble versions of those pills [20]. Adsorption involves getting ready a solution of the drug and mixing it with an insoluble powder so as to adsorb the drug, removing the solvent, drying the consequent powder, and then the use of these dried adsorbates in the instruction of the very last dosage shape. Many substrates like veegum, bentonite, silica gel and silicates may be used for the reparation of adsorbate of bitter capsules. The sour taste of ranitidine is masked through forming an adsorbate with an artificial cation trade resin [21].

Taste Protecting by Means of Gelation

Water insoluble gelation on the surface of tablet containing bitter drug can be used for flavor masking. Sodium alginate has the potential to cause water insoluble gelation in presence of bivalent steel ions. Tablet of amiprolose hydrochloride had been taste masked by means of applying an undercoat of sodium alginate and overcoat of calcium gluconate. In presence of saliva, sodium alginate reacts with bivalent calcium and shape water insoluble gel and for that reason flavor overlaying performed [22].

Multiple Emulsions

A unique method for flavor overlaying of medicine employing a couple of emulsions has been prepared through dissolving drug within the inner aqueous section of w/o/w emulsion below conditions of proper shelf balance. The formula is designed to release the drug thru the oil segment inside the presence of gastrointestinal fluid [23,24].

Development of Liposome

Every other way of protecting the unpleasant flavor of therapeutic agent is to entrap them into liposome [25]. For example, incorporating right into a liposomal method organized with egg phosphatidyl choline masked the sour flavor of chloroquine phosphate in HEPES (N-2-hydroxyetylpiperzine-N- 2- ethane sulfonic acid) buffer at pH 7.2.

Evaluation Techniques

Sensory evaluation

Flavor, to consider, is a completely subjective perception. Relying on individuals, the perceived taste may also vary to extraordinary stages. If we've got properly controlled experimental installation, its miles viable to as it should be and reproducibly degree flavor thresholds. To quantitatively evaluate flavor sensation, following methods are:

a. Panel trying out (human topics)

b. Measurement of frog flavor nerve responses.

c. Multichannel taste sensor/ magic tongue

d. Spectrophotometric assessment/ D30’s value.

The panel testing

In this technique, a collection of about 5â€ÂÂ10 human volunteers is skilled for flavor evaluation by means of the usage of reference solutions ranging in flavor from tasteless to very bitter. Numerical values are then assigned to these tiers of bitterness (e.g., zeroâ€ÂÂfive). Subsequently, test answer is tasted and rated at the identical scale to evaluate its bitterness. Literature reports panel testing in invariably all the tasteâ€ÂÂmasked capsules being evaluated [26].

Dimension of frog taste nerve responses

Located and dissected from the encompassing tissue and reduce proximally. An acâ€ÂÂamplifier and a digital integrator are used to respectively extend and combine the nerve impulses. The height of the incorporated reaction is then taken as the significance of response [27].

Multichannel flavor senzsor/magic tongue

This is an automated taste sensing tool to hit upon the magnitude of bitterness of a drug substance. The device has a transducer which consists of numerous forms of lipid/polymer membranes with specific traits that could come across taste in a manner similar to human gustatory sensation. Flavor reaction is transferred into a sample composed of electric indicators of membrane potentials of the receptor element. Specific reaction electric ability pattern are acquired for substance producing distinct flavor characteristics [28].

Currently, the technique has been carried out, for the quantitative assessment of the bitterness of some commercially to be had drugs. Quinine hydrochloride became taken as the standard for bitterness.

Spectrophotometric method

A known quantity of the tasteâ€ÂÂmasked components is blended with 10 mL of distilled water in 10 mL syringe by means of resolving the syringe, end to stop; 5 times in 30 seconds. The check medium is then filtered via a membrane clear out, observed through spectrophotometric willpower of the attention of the drug inside the filtrate. If this awareness is below the brink concentration, it is able to be concluded that the sour taste would be masked in vivo. This method has been carried out to evaluate the taste masked granules of sparfloxacin, with threshold attention being 100 μg/mL (Table 6).

Table 6: List of drug, excipients and techniques used for the preparation of taste masked product.

| Drug | Technique | Excipients |

|---|---|---|

| Eucalyptus oil | Flavors and sweeteners | Fenchone, borneol |

| Acetaminophen | Microencapsulation wurster fluid bed coating | Crosscarmellose |

| Ampicillin trihydrate | Spray drying | Sodium CMC |

| Ibuprofen | Flavors and sweeteners | Saccharin sodium, sucrose, sorbitol solution |

| Nizatidine | Spray drying | Eudragit E-100 |

| Polylactic acid | Multiple emusion | Brilliant blue dye |

| Erythromycin | Ion exchange resins | Carbomer 934 |

| Paroxetin HCL | Ion exchange resins | Amberlite IRP88 |

| Benexate hydrochloride | Complexation | Cyclodextrin |

Conclusion

Diverse techniques mentioned herein can assist conquer sour flavor of API (Active pharmaceutical Ingredients) as well as in large part improve the product choice among patients. It'll also beautify the great of the treatment furnished to sufferers, in particular youngsters and older sufferers. Also, numerous techniques will be combined to increase palatable and pricepowerful system.

References

- Sohi H, Sultana Y, Khar RK (2004) Taste masking technologies in oral pharmaceuticals: recent developments and approaches. Drug Dev Ind Pharm 30: 429-448.

- www.umds.ac.vk/physiology/jim taste olf.htm.

- www.cf.ac.vk.biosi/staft/jacob/teaching/sensory/taste.htm.

- www.foodiesite.com/articles/2000-11/cheese.jsp

- Gyton C (1986) The chemical sensesâ€ÂÂTaste and smell. In: Textbook of Medical Physiology, (7th edn.), Saunders Company, Hong Kong, WB, p: 745.

- Chatap V K. A Review on Taste Masking Methods of Bitter Drugs.

- Kuchekar BS, Badhan AC, Mahajan HS (2003) Mouth Dissolving Tablets A Novel Drug Delivery System. Pharma Times 35: 7-9.

- Mauger JW, Robinson JR, Dennis H (1998) US Patent. 5: 728, 403.

- Zelalem A, Puri V, Kumar L, Bansal A (2009) Trends in Pharmaceutical Taste Masking Technologies: A Patent Review. Recent Patents on Drug Delivery & Formulation 3: 26-39.

- Lachman L, Lieberman HA, Kanig JL (1987) Liquids The Theory and Practice of Industrial Pharmacy, (3rd edn.), pp. 419-427.

- Zelalem A, Puri V, Kumar L, Bansal A (2009) Trends in Pharmaceutical Taste Masking Technologies A Patent Review. Recent Patents on Drug Delivery & Formulation 3: 26-39.

- Roche JE, Reo PJ (1994) Rotogranulations and taste masking coating for preparation of chewable pharmaceutical tablets. US Patent No.5320855.

- Davis JD (2000) Drug Cosmet India Encyclopedia of Pharmaceutical Technology.

- Jain N K (2001) Advances in controlled and Novel Drug delivery, (1st edn.), pp: 290-306.

- Roy GM (1994) Taste masking in oral pharmaceuticals. Pharm Tech 18: 84-99.

- Tsau J, Damani N (1993) Taste masking compositions. US Patent No. 5286489.

- Brahamnkar DM, Jaiswal SB (1998) Prodrugs in Biopharmaceutics and Pharmacokinetics A Treatise. Vallabh Prakashan, Delhi, p: 163.

- Kulkarni G, Menjoge R (2005) pH sensitive polymer and process for preparation thereof. US Patent No.20050137372.

- Popli S, Zenaida O (1997) Go Taste masking liquids. United States Patent No. 5,616,621.

- Sharma S, lewis S (2010) Taste masking technologies a review. International Journal of Pharmacy and Pharmaceutical Sciences 2: 6-13.

- Douglas S, Bird F (1993) Drug adsorbates.US Patent No. 5219563.

- Kaning K, Kanada K (1997) Application of gel formation for taste masking. Chem Pharm Bull 45: 1063-1068.

- Rosoff M (1988) Pharmaceutical dosage form disperse system 1: 245-283.

- Rao YM, Bader F, Maura L (1993) Masking the taste of chloroquine by multiple emulsion. The East Pharm 11: 123.

- Kasturagi Y, Sugiura YC, Otsugi K (1995) Selective inhibition of bitter taste of various drugs by lipoprotein. Phram Res 15: 658-662.

- Swarbrik J, Boylan SC (1990) Flavors and flavors modifier. In Encyclopedia of Pharmaceutical Technology 6: 117â€ÂÂ137.

- Katsurgi Y, Kashiwayanagi M (1997) Specific inhibitor for bitter taste inhibition of taste nerve responses and human taste sensation to bitter stimuli. Brain Res Protocols 1: 292â€ÂÂ298.

- Takagi S, Toka K (1987) Detection of suppression of bitterness by sweet substance using a multichannel taste sensor. J Pharm Sci 87: 552â€ÂÂ555.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences