Simple and Time Saving Combination Technique for Fabricating an Ocular Prosthesis

Pankaj Kharade1*, Kanchan Dholam2 and Gorakh Ahire2

1Department of Prosthodontics, Dr.Z.A Dental College and Hospital, Aligarh Muslim University, Aligarh, India

2Department of Dental & Prosthetic Surgery, Tata Memorial Hospital, Mumbai, India

- Corresponding Author:

- Kharade P

Department of Prosthodontics

Dr.Z.A Dental College and Hospital

Aligarh Muslim University, Aligarh, India

Tel: +918859990440

E-mail: drpankaj_07@yahoo.co.in

Received Date: May 30, 2017; Accepted Date: August 24, 2017; Published Date: August 28, 2017

Citation: Kharade P (2017) Simple and Time Saving Combination Technique for Fabricating an Ocular Prosthesis. Pros Orth Open J. Vol. 1 No. 2: 13.

Copyright: © 2017 Kharade P. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

In the traditional method of fabricating custom ocular prosthesis, investment of impression is a taxing step due to it’s influence on retrieval of the wax pattern and it’s trial. Mould preparation to invest the ocular impression is a tedious and time consuming procedure.

The following article describes a simple and time saving laboratory method of fabricating an ocular prosthesis by using conventional materials for precise fit and esthetic treatment outcome. This technique bypasses tedious step of mould fabrication. It also describes convenience of a special device fabricated from conventional materials for making ocular impression.

Keywords

Ocular prosthesis; Orbital prosthesis; Prosthodontic rehabilitation; Enucleation; Evisceration; Excenteration

Introduction

Mutilation resulting from loss of an eye can considerably affect communication and psychosocial behavior [1,2]. Due to development in ophthalmic surgical procedures and maxillofacial prosthodontics science an ocular patient can be rehabilitated very successfully.

The surgical procedures in the removal of an eye are classified into three categories viz. enucleation, evisceration, and excenteration. After enucleation, when surgical site is well healed and dimensionally stable, fabrication of an ocular prosthesis may be undertaken. Prosthetic rehabilitation can be done either with stock eye prosthesis (prefabricated) or custom made ocular prosthesis. Custom prosthesis offers precise fit and esthetics [3,4].

The need for an artificial eye can sometimes be satisfied by stock prostheses that are available in standard sizes, shapes, and colours [5-7].

But both the techniques are having certain advantages and disadvantages. This article describes a simple and time saving laboratory method of fabricating an ocular prosthesis by combination of custom and stock ocular prosthesis technique for precise fit and improved treatment outcome of ocular prosthesis.

The technique presented has following advantages:

• This technique is simple and less time consuming as compared to other methods of fabrication of orbital prosthesis.

• Investment of ocular impression is easy as mould fabrication step is bypassed.

• Reduces the time interval between impression and try in, thus it makes possible the impression and try in of the wax pattern of the prosthesis on the same appointment.

• This technique leads to esthetic treatment outcome.

• This technique utilizes conventional prosthetic material for fabrication of the device and custom ocular prosthesis.

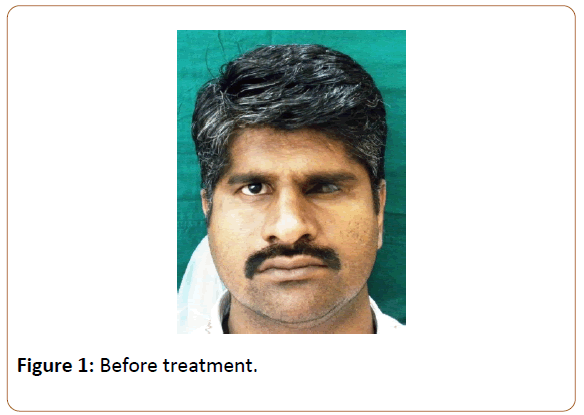

A 45-year-old male patient was referred for opinion regarding prosthodontic rehabilitation of ocular defect (Figure 1). On clinical examination ocular defect as an end result of left eye enucleation was found. The patient revealed history of rhabdomyosarcoma of the left eye leading to surgical enucleation as a part of treatment.

On examination the ocular defect was healed properly with minimal mobility of the posterior wall of the ocular defect during full excursive movement. Assessment of the muscular control of the palpebrae and the internal anatomy of the socket in resting position was also done.

The palpebral fissure was examined in both open and closed position to rule out any anatomical as well as physiological abnormality. Conjunctiva, depth of fornices, and presence of cul de sac was also examined. It was planned to rehabilitate the patient with ocular prosthesis fabricated by combination of custom and stock ocular prosthesis technique.

Procedure

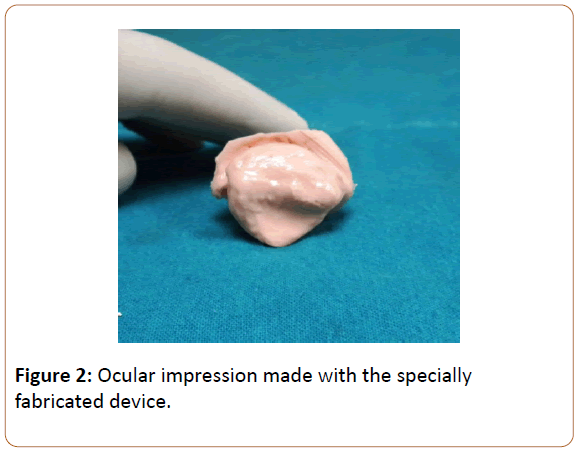

A special device was fabricated with autopolymerizing resin and 20 gauge stainless steel wire. This device is having multiple loops. It is possible to adjust the device by compressing, opening or bending the loops in various planes as per dimension of the ocular defect. Impression of the ocular defect was made with irreversible hydrocolloid impression material (Jeltrate Type II, DENTSPLY Caulk) with the specially fabricated device (Figure 2).

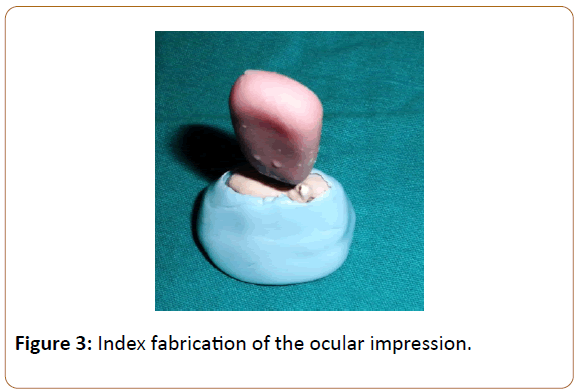

The impression was disinfected. Addition silicone soft putty material was adapted properly around the hydrocolloid impression to form a mould (Figure 3).

After setting of the rubber base mould was cut in a crisscross manner so as to make two separate parts as shown in the (Figure 4).

This crisscross pattern will act as an index and will help for precise re-adaptation of the mould parts. It will also restrict the movement of the mould surface after adaptation. Inner hydrocolloid material is removed by separating two halves. Two halves were adapted against each other and melt modeling wax was poured in the empty space.

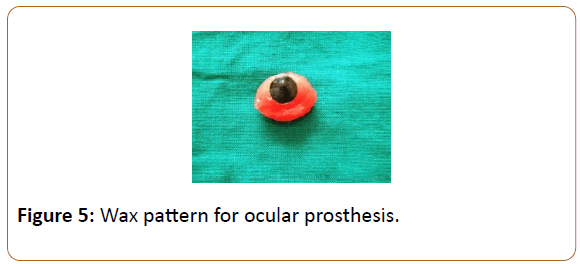

After cooling of the wax it was removed by separating two halves of the silicone index and try in was done. After try in necessary changes were done in the wax pattern. Position of the iris was marked with accurate gaze of the patient. Shade of the iris of patient’s eye was matched with a prefabricated stock eye. Iris portion of the stock eye was cut and incorporated in the wax pattern in the desirable location (Figure 5).

Again the wax pattern was inserted in the ocular defect and patients gaze was checked. Necessary changes were made in the wax pattern as per requirement. After try in procedure wax pattern was invested in crown flask (The Hanau recon Flask, Buffalo, New York, U.S.A.) with dental stone (Kalstone, Kalabhai, Mumbai, India). Before pouring the upper portion a small acrylic tag was placed in the iris portion so that after dewaxing the iris portion will be retained in the upper part of the crown flask (Figure 6).

Dewaxing was done. After dewaxing separating medium (Cold mould seal, DPI, Mumbai, India) was applied on inner mould surface. Tooth colored heat polymerizing resin with similar shade of sclera of patient was packed in the mould space. Curing was done with certain modification to follow a protocol referred to as ‘reverse curing’ which was reported by Jorge and coworkers [8].

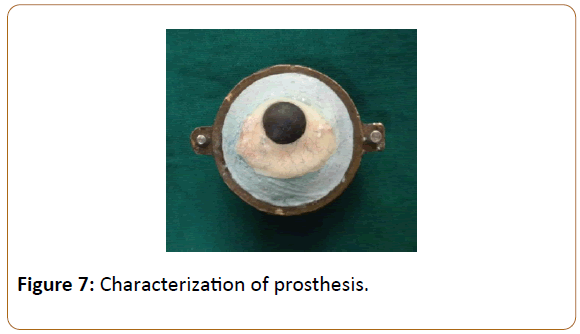

In this technique, the flask was placed in water at 95°C for 20 minutes and thereafter in boiling water for an additional 20 minutes. The flask was cooled by holding it under running water. This modification in the curing cycle minimizes residual monomer content from the cured ocular prosthesis. After curing flask was opened and approximately 1 mm thickness of acrylic was removed from entire surface of the cured prosthesis (Figure 7).

Characterization was done with acrylic paints and flocking of different shades in the presence of patient to avoid any disparity with the contra lateral eye. Flocking was retained with the help of bonding agent application followed by curing.

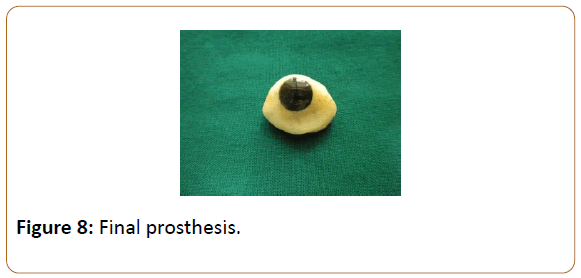

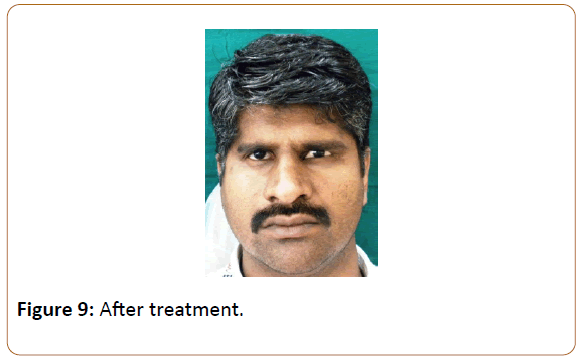

After application of acrylic paints and flocking a layer of clear heat polymerizing resin was applied and the crown flask was closed and again curing procedure was carried out. After curing prosthesis was finished with burs (Patterson Dental, U.S.A.) and polished (Figure 8). Prosthesis was inserted in the ocular defect region (Figure 9). Hygiene instructions were given and patient was called for regular follow-up.

Discussion

In the present technique special device was fabricated to make ocular impression. It is simple to fabricate and requires less armamentarium. This device can be modified as per size and extent of the ocular defect in various planes. Apart from that silicone index fabricated from ocular impression bypasses tedious step of mould fabrication. It also reduces the time internal between ocular impression and try in. The use of a prefabricated ocular prosthesis of a suitable size and color, adapted by selective grinding or additions of acrylic resin may produce outstanding results for most patients depending on satisfactory selection of prefabricated eyes. However there may be tremendous disparity and miscellaneous types of ocular injuries present. Certain patients would benefit more from custom made ocular prostheses which are fabricated as per their needs and characteristics of contra lateral eye ball. This procedure is a combination of both techniques leading to additional benefits for the patients.

Summary

This technique bypasses tedious laboratory procedure making it simpler for use. The technique provides an ocular prosthesis with precise fit and esthetics in a short period of time. As the prosthesis is fabricated in heat polymerizing resin, it shows fewer chances of allergic reactions as compared to chemically polymerizing resin. The special device used for ocular impression making is easy to fabricate with less expensive armamentarium and can be modified as per requirement in various clinical situations. This technique is very easy to learn. This technique is very simple as indexing is done from anterior aspect. As it is a combination technique, it helps to improve the cosmetic appearance of the patient.

References

- Lubkin V, Sloan S (1990) Enucleation and psychic trauma. Adv Ophthalmic PlastReconstrSurg 8: 259–262.

- Schneider RL (1986) Modified ocular prosthesis impression technique. J Prosthet Dent 55: 482–485.

- Artopoulou I, Montgomery CP, Wesley IP, Lemon CJ (2006) Digital imaging in the fabrication of ocular prostheses. J Prosthet Dent 95: 327–330.

- Bartlett SO, Moore DJ. (1973) Ocular prosthesis: A physiologic system. J Prosthet Dent 29: 450–459.

- Rahn AO, Boucher LJ (1970) Maxillofacial Prosthetics: Principles and Concepts. Philadelphia, PA, Saunders.

- Chalian VA (1979) Treating the patient with facial defects: Maxillofacial Prosthetics.

- Sykes LM (1996) Custom made ocular prostheses: A clinical report. J Prosthet Dent 75: 1-3.

- Jorge JH, Giampaolo ET, Vergani CE, Machado AL, Pavarina AC, et al. (2007) Biocompatibility of denture base acrylic resins evaluated in culture of L929 cells. Effect of polymerisation cycle and post-polymerisation treatments. Gerodontology 24: 52–57.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences