Evaluating the Impacts of Regional Transport and Monsoons on the Air Quality in Nanjing Based on VAR Model

Zhongwen Huang1,2,3, Huiling Zhang1,3, Lei Tong1,3, Jingjing Zhang1,3,4, Jinsheng Chen1, Wenpo Shan1,3 and Hang Xiao1,3*

1Center for Excellence in Regional Atmospheric Environment, Institute of Urban Environment, Chinese Academy of Sciences, Xiamen 361021, China

2School of Chemistry and Environmental Engineering, Hanshan Normal University, Chaozhou 521041, China

3Ningbo Urban Environment Observation and Research Station-NUEORS, Chinese Academy of Sciences, Ningbo 315800, China

4University of Chinese Academy of Sciences, Beijing 100049, China

- *Corresponding Author:

- Hang Xiao

Institute of Urban Environment

Chinese Academy of Sciences

1799 Jimei Avenue, Xiamen, 361021

China

Tel: +0574-86784813

E-mail: hxiao@iue.ac.cn

Received date: December 05, 2017; Accepted date: December 25, 2017; Published date: January 05, 2018

Citation: Huang Z, Zhang H, Tong L, Zhang J, Chen J, et al. (2018) Evaluating the Impacts of Regional Transport and Monsoons on the Air Quality in Nanjing Based on VAR Model. Glob Environ Health Saf Vol.2 No.1:1.

Abstract

Heavy air pollution occurred frequently in Nanjing in recent years. To estimate local and regional source contributions of air pollutants (PM2.5, SO2, NO2, CO) in Nanjing during different seasons, the air monitoring data between January 2015 and April 2016 was collected from China National Environmental Monitoring Center and analyzed with time series approach of Granger causality test and vector autoregressive (VAR) model. It is found that the correlations of pollutions among cities during Southeast prevailing wind (SP) period were weaker than North prevailing wind (NP) period, partly due to low pollution level in SP period. The Granger causality tests indicate that there were more causal relationships of air pollutants between Nanjing and 9 surrounding cities in NP period partly due to heavier regional pollution and the causalities were not always consistent with prevailing wind direction. Variance decomposition in VAR model suggests that local source played a more important role than regional source during SP period, as it donated 68.6%, 65.3%, 69.7% and 76.9% for PM2.5, SO2, NO2 and CO, respectively. However, Nanjing was strongly affected by regional transport during NP period, as North direction contributed 64.4%, 58.1%, 60.2% and 56.8% of PM2.5, SO2, NO2 and CO in Nanjing, respectively. Furthermore, the observed air pollutant concentrations in Nanjing were well consistent with the model-simulated results, except highly active pollutant of NO2. These results indicated that the time series approach could be a simple tool for understanding the impacts of regional transport and monsoons the air quality in a particular city.

Keywords

Aerial pesticide applicators; Aviation crashes; Pesticides; Aircraft; Occupational injury

Introduction

On-the-job deaths related to aviation are the seventh leading cause of fatal occupational injury in the United States [ 1]. The prominence of general aviation in work related fatalities indicates a need for greater attention to the safety of aerial pesticide applicators whose job entails flying many hours on a daily basis and multiple times a day. According to data reported by the Bureau of Labor Statistics, there were 38,170 individuals employed as commercial pilots, which aerial pesticide applicators are listed under [2].

Aerial pesticide application is often the most effective and economical way to apply pesticides to crops and permits large and remote areas to be treated rapidly, three times faster than conventional pesticide application; aerial application is by far superior to any other crop pesticide application method as it does not result in crop damage or soil runoff and it eliminates cross contamination of pesticide from one field to the next [3]. According to the National Agricultural Aviation Association [4] (NAAA) aerial application is also conductive to higher crop yields due to the fact this application method is not disruptive to the crop as crops are treated from above. Aerial pesticide application is beneficial to the environment/ecosystem as it results in less land being destroyed for agricultural production, which in turns protects important ecosystems such as wetlands and forests in regards to water filtration and carbon sequestration and threatened and endangered species from destruction [5].

According to the National Agricultural Aviation Association [ 3], aerial applicators are located in 46 states; states where applicators are not located are Alaska, New Hampshire, Rhode Island and Vermont [5]. Aerial pesticide application generally involves low flying maneuvers in different terrains, at all times of the day/night and in different weather conditions. Aerial pesticide applicators are usually highly trained individuals with an average of over twenty years of experience. In the United States, there are approximately 1,350 aerial applicator businesses and 1,430 non-operator pilots. Within the 1,350 applicator businesses in the United States, 94% of the owners are also pilots [5].

The summer months (Memorial Day through Labor Day) are when the majority of agricultural crops are grown, which accounts for the increase in risk of injury or death for pesticide applicators. During the last decade, aerial pesticide applicator crashes during the months of May-September accounted for 76% of all accidents [6]. Since 1976 aerial pesticide applicators have been increasingly conducting night pesticide applications, especially in the Southwestern United States. The reasoning for the increase is primarily to avoid heat; however, nighttime application also increases the risk of accidents in the population [7].

Types of aircraft

The United States Department of Agriculture (USDA) Economic Research Service Report 2007 states that within the United States there are 408 million acres of cropland and approximately 70% or 286 million acres are commercially treated with crop protection products (pesticides) [8]. Specifically, aerial pesticide applicators treat 71 million acres of croplands per year. Aerial pesticide application accounts for approximately 20% of all applied crop protection products on commercial farms and close to 100% of all forest protection applications [5]. Aerial application is applicable for many types of crops. A 2012 survey conducted by the NAAA [2] determined that the five most common crops that aerial pesticides are applied to are corn, wheat/barley, soybeans, pastures/rangelands and alfalfa [5].

The majority of the pesticide application fleet are fixed wing aircraft (87%), while the remaining aircraft are rotorcraft/ helicopter (13%). These aircraft are ruggedly built and generally handle approximately thirty-to-one hundred take offs and landings every day from rugged landing strips (the majority of aerial applicators do not use public airports). Modern pesticide aircraft have sophisticated technology like GPS, GIS, which gives real time and up to date topographical information. Typically, the majority of pesticide aircrafts have “real time” meteorological systems on board to keep up to date weather information. These pieces of technology help pilots improve safety conditions during application runs. In addition, aerial applicators are considered restricted category aircraft and are less likely to show up on FAA radar technologies (air traffic control systems) due to these aircraft flying at low altitude in uncongested airspace [5].

Training and safety

Training and safety data on aerial pesticide applicators reveals that the average aerial pesticide applicator has approximately 21 years of experience in the industry and the aerial applicator operator has approximately 27 years of experience in the industry [5].

Pilot certification

The requirements for obtaining a commercial pilot license is often a lengthy and strenuous process. For example, aerial pesticide applicators must have their commercial pilot’s license to fly these aircraft, be registered as commercial pilots in their respective states and obtain the respective pilot license in their state of operation [9].

Pilot certification is governed under the Federal Aviation Administration (FAA) under the Code of Federal Regulations Part 61 of the Federal Aviation Regulations [10]. In order to receive a commercial pilot license, one must first hold a private pilot license, be at least 18 years old, have an understanding of the English language and also be able to speak and write in English. Pilots should meet the aeronautical experience requirements of the FAA section that they are applying for and also in the aircraft category they would be operating (i.e., agricultural section and agricultural aircraft), pass a written knowledge test, and pass a practical examination administered by the FAA or someone designated by the FAA to give this exam [11].

Rationale

There is limited amount of data/studies that look at aerial pesticide applicator crashes that result in injury and death with the last major update in the medical literature on aerial pesticide applicator crashes published in 2001. The primary purposes of this study are to quantify aerial applicator crashes and examine factors associated with these crashes; and to determine where in the United States most of the crashes are occurring; during what months or time of the year these crashes are occurring; the types of aircraft involved in crashes (fixed wing vs. rotatory); quantify the average flight experience of pilots involved in these crashes and determine if this influences crash statistics; to quantify when and why these crashes are occurring (i.e., during landing, takeoff, during application); and finally to understand what factors (i.e., weather, pilot error or striking a stationary object) influence these crashes. The implications for conducting public health surveillance of aerial pesticide applicators may lead to a heightened awareness of deaths and injuries among health and safety professionals and to provide information that better equips pilots and pesticide applicators to better respond to crashes by designing more effective control measures and training that leads to the eventual reduction of aerial pesticide applicator crashes in the United States.

Methods

Sample selection

The sample population included all licensed aerial pesticide applicators in the United States from 1995-2013, involved in a crash investigated by the National Transportation Safety Board (NTSB) or the Federal Aviation Administration (FAA). The specific inclusion criteria dates are crashes occurring between 01/01/1995 and 12/31/2013. The FAA maintains a database on aircraft crashes that occurred in the United States [12]. The FAA Accident/Incident Data System (AIDS) database contains data records for general aviation and commercial air carrier incidents since 1978. The operation type (search query on the AIDS database) for these type aircraft involved in pesticide application is FAA Part Flight Conduct: Agricultural. The Aviation Safety Information Analysis and Sharing (ASIAS) database for AIDS contains only a limited number of incidents The AIDS database contains incidents or events that do not meet the aircraft damage or personal injury thresholds set by the NTSB accident definitions. This means even if the incident/ crash did not cause damage to the aircraft to reach the NTSB threshold, the FAA maintains that the incident still provides valuable safety information that may be used in future interventions.

Criteria by Bensyl [13], defines a work-related crash as “a crash in which an individual on the aircraft was carrying out a work-related function.” An operational definition of an aerial applicator is all licensed applicators, licensed by an accrediting body in the time period 1995-2013, who have identified themselves as an “aerial applicator” and are listed in the FAA AIDS crash database. For consistency, the terms “accidents” and “crashes” are used interchangeably (as noted by the FAA and NTSB) in this study. A pesticide application run is when the aircraft conducts a normal pesticide application “run”; take off, application and landing.

The FAA AIDS database contains variables on probable, factual or preliminary cause of the accident (i.e., what happened, the outcome, and the investigation narrative), if the accident was fatal or nonfatal, the make and model of the aircraft that was involved, location (city and state) of the accident, company involved and the date of the accident, total pilot experience, total pilot experience in specific aircraft, aircraft damage, flight phase (i.e., landing, takeoff, normal operations). From the FAA AIDS database, general information about the group was determined (i.e., basic demographic information), and circumstances of the fatal injury or non-fatal injury were evaluated) Factors causing the crashes in this group were examined (i.e., weather, human error, running into natural or man-made objects, mechanical failure). Patterns and trends of crashes were analyzed over time.

Data analysis

The data were downloaded and analyzed in SPSS v20 (IBM SPSS Statistics for Windows, Version 20.0). Descriptive and statistical analysis of basic demographics, type of aircraft and year’s experience were calculated using mean, medians and modes. Because of the rarity of fatalities and injuries in this group, Poisson regression was used to evaluate pilot experience and flight phase (i.e., take off, landing, basic operations) and relationship in regards to crashes, injuries and fatalities. Calculating the mean, median and standard deviation of pilot experience applying pesticides dichotomized pilot experience (total flight hours) and the individual experience either falls above or below the mean. Basic descriptive statistics (frequencies) were calculated for the variables in the group (i.e., severity of aircraft damage, flight phase of crash, aircraft type and pilot certification type). Chi square or Fischer exact tests were conducted as appropriate between types of certification the pilot involved in the crash held (i.e., flight instructor vs. commercial pilot vs. student pilot verses foreign pilot/other), types of aircraft (fixed wing or helicopter), damage done to the aircraft (i.e., destroyed) to determine the relationship between these variables and injuries/fatalities (Values were considered statistically significant at the p<0.05 level).

Measures to determine factors associated with aerial pesticide applicators were identified (i.e., age of plane being operated, experience of pilot (total flying time), total flying time on specific aircraft that was involved in the crash, low flying maneuvers, running into objects, type of license held by pilot involved in crash These factors were analyzed for their association in aerial crashes. ArcGIS 10.2.2 was used to create a map of the United States in relation to the number of crashes in each state over the study period, 1995-2013.

This study did not contain any personal identifiers and received an exemption from East Carolina University, IRB (UMCIRB 14-001116).

Results

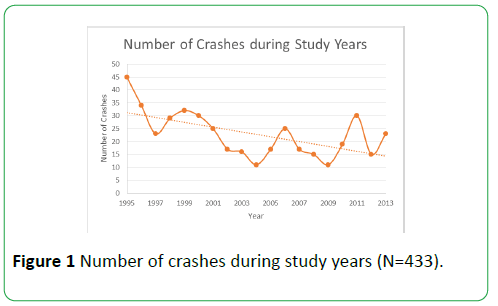

The total sample size was 433 subjects. Figure 1 shows the number of crashes during the study time period (1995-2013), the year with the highest crashes was 1995 (45 crashes). There were a reduction in crashes from 1995 to 1997 with a slight increase from 1998 to 2000, followed by a decrease in crashes except for 2006 (25 crashes), again a reduction in crashes except in 2011 (30 crashes). The overall trend for crashes over the study period is that crashes have generally gone down since 1995.

The total number of aerial pesticide applicator crashes by state over the study period was found to be 433. Arkansas saw (46 crashes) or 10.62 percent, which was the most crashes during the study period, followed by Texas (39 crashes) or 9.01 percent, Louisiana (36 crashes) or 8.31 percent, California (33 crashes) or 7.62 percent and Nebraska with 16 crashes or 3.70 percent. North Carolina reported 10 crashes or 2.31 percent during the study period. West Virginia, Utah and New Mexico all tied for the least number of crashes, 1 crash in each state or 0.23 percent of crashes.

Table 1 shows the average flying (flight) experience of this group is 9104.51 hours (standard deviation 7948.25 hours). The upper range of flying experience in this group was 40,500 hours.

| Mean | 9104.51 hours |

| Median | 7000 hours |

| Standard Deviation | 7948.25 hours |

| Maximum | 40500 hours |

Table 1. Total flight experience of the group (N=387).

As shown in Table 2, the flight experience in flight hours of the group in respect to the average (mean) flight time experience; 58% of the group had below the average flight time experience with 41% who had above the average flight time experience.

| Percentage | Count | Mean | |

|---|---|---|---|

| >9104.51 | 41.86% | 162 | 9149.97 hours |

| <9104.51 | 58.14% | 225 | 9097.01 hours |

Table 2. Percentage of group over and under the mean pilot experience time (N=387).

Overall, there were three (3) fatalities and 13 different types of (non-severe) injuries out of the 433 total cases.

The majority of pilots in the group (301, 69.5%) held a commercial pilot’s license. A flight instructor license, private pilot license and unknown type of license were held by 78 (18%) of pilots in the group. An airline transport pilot flight instructor license was held by 16 (3.7%) of pilots in this group. There were no significant differences between the type of certification held by the pilot involved in the crash and whether they experienced an injury/fatality (p=0.604). As shown in Table 3, all pilots had a total flight time/experience of 3,523,447 hours (mean 9104.51 hours, standard deviation 7948.25 hours). All pilots had a total flight time/experience in the specific make-model of aircraft they were involved in a crash in of 957,996 hours (mean 2527.69 hours, standard deviation 3633.72 hours). All pilots had a total flight time/ experience within the last 90 days on all aircraft for 54,600 hours (mean 146.38 hours, standard deviation 117.62 hours). All pilots had a total flight time/experience within the last 90 days on that specific make-model of aircraft that was involved in a crash of 12,004 hours (mean 146.39 hours, standard deviation 121.41 hours) as shown in Table 3.

| Pilot in Control Flight Time Total Hrs | Pilot in Control Flight Time Total Make-Model | Pilot in Control Flight Time 90D Total Time | Pilot in Control Flight Time 90D Total Make-Model | ||

|---|---|---|---|---|---|

| N | Valid | 387 | 379 | 373 | 82 |

| Missing | 46 | 54 | 60 | 351 | |

| Median | 7000 | 1080 | 116 | 100 | |

| Std. Deviation | 7948.25 | 3633.72 | 117.615 | 121.413 | |

| Minimum | 0 | 0 | 0 | 2 | |

| Maximum | 40500 | 28500 | 800 | 600 | |

Table 3. Total flight time experience, total flight time in the make-model of aircraft involved in crash, total flight time in the last 90 days of the group and the total flight time in the last 90 days of the group in an aircraft involved in the crash.

The majority of aircraft used in this group were fixed wing aircraft 390 (90.1%). The use of helicopters to apply pesticides aerially was 40 (9.2%). Table 4 demonstrates that in only 1 (0.2%) of the 433 crashes was the aircraft completely destroyed. In 390 (96%) of the 406 aircrafts that were involved in crashes, some form of damage was reported. In 363 (84%) of crashes the aircraft suffered minor damage, 16 aircraft suffered no damage at all during their crash and 26 (6%) aircraft suffered substantial damage (the aircraft would require major repair or replacement of the affected area/ component) during the crash [14].

| State of aircraft involved in crash | Frequency | Percent |

|---|---|---|

| Destroyed | 1 | 0.2 |

| Minor damage | 363 | 83.8 |

| Substantial damage | 26 | 6 |

| None | 16 | 3.7 |

Table 4. Frequency of aircraft state after crash (N=406).

There was no significance between the type of aircraft the operator used and whether they experienced an injury/fatality (p=0.38). There was also no significance between the damage sustained by the aircraft in the crash and whether they experienced an injury/fatality (p=0.625).

Looking at the description of injuries of the applicators showed a pilot that was fatally injured when they exited the aircraft, while it was still running, to assess damage (the aircraft sustained minimal damage) to the alternator after an incident and was struck and fatally injured by the propeller. Another minor incident occurred when an aircraft struck a bird, broke through the cockpit windshield. The pilot sustained minor facial injuries and landed the aircraft safely. Due to an internal power loss to the aircraft, the pilot made an emergency landing and sustained minor injuries. These injuries were not specified in the database. An incident in a rotary aircraft (Bell make) occurred when the aircraft struck power lines and a small fire was ignited in the area. The pilot landed the craft safely and sustained minor injuries.

The majority (136, 31.4%). of crashes in this group happened during low-level operations. Aerial pesticide applicators usually fly at low levels to appropriately and effectively apply pesticides; low level operations would be a very common tactic used by this group. 40 (9.2%) happened due to roll out; this is for fixed wing aircraft only. Surprisingly, only 12 (2.8%) of crashes happened from take off, 16 (3.7%) of crashes happened due to a forced landing or precautionary touchdown.

Pesticide applicators with less experience were 1.3 times more likely to be injured and/or die, but this data are not significant (p=(0.639). If the pesticide applicator was performing normal operations/flying maneuvers they are 1.8 times more likely to crash and experience injury/fatality, but this was not significant (p=0.254).

The number of crashes for the complete study was broken up into 2 parts (6 month intervals) of the year (Jan-June and July-December). The July-December time period had the most cases (235, 54% cases), while Jan-June period had only 198 (46%) cases.

The number of crashes (N=433) were then broken up between Spring/Summer months (May-September) and the rest of the year (October-April). The summer months overwhelmingly had more crashes (334, 77%) than the rest of the year (99, 23% of crashes).

Discussion

Aerial pesticide application is an important tool to control pests on agricultural and forestry lands. However, aerial application of pesticides can be dangerous for the applicator.

Seventy-seven percent of aerial applicator crashes in this study happened during May-September. A study of agriculturally related aircraft crashes from the years 1992-2001 also determined that the majority of crashes occurred during the summer months (May-September). The majority of crashes occur during the summer months as this is considered the “busy season” for agriculture workers as the majority of planting/growing would occur during this time [15].

There were only 16 injuries (including 2 fatalities) reported among this group. One of the original fatalities was miscategorized by the FAA Database and was removed from the sample. It was determined that this case was not a fatality. Because there were few injuries fatalities among this group, this could account for the non-significance of the statistical findings. The majority of aircraft that crashed were determined to suffer minor or no damage of 379 aircraft out of 406 total aircraft (93%). It is possible that the aircraft build and structural integrity protected the applicator from serious harm and why few deaths were reported.

The majority of aircraft used by the group were fixed wing aircraft. Other studies have also shown that fixed wing aircraft were most commonly used over rotary blade. The majority of crashes were related to low level operations, this is not surprising as aerial pesticide aircraft generally fly low to release the pesticide and pull up quickly and return to reapply again or land the aircraft. Since these aircraft fly low, it makes them more prone to running into objects such as trees, mountains, manmade objects and/or power lines as examples. The NAAA looking at data from aerial pesticide applicator crashes over the past 10 years found that 7.2% of aerial applicator fatalities were due to the aircraft colliding with towers, collision with power lines accounted for 12.3% of accidents and 13% of fatalities (National Agricultural Aviation Association) [3].

Fewer hours of flight time experience in the previous 90 days in the aircraft that crashed may have been a factor in the crash due to more unfamiliarity of the planes operation and maneuverability. The vast majority of this group had a commercial pilot’s license, as aerial pesticide applicators are required by law to hold a commercial pilot’s license. Only 33 (8.1%) of the group did not have a commercial pilot’s license (they identified themselves as a private pilot, unknown license or a foreign pilot license or were considered airline transport with specification on a commercial license). It is not known why these pilots answered the question that way.

Arkansas, California, Texas and Louisiana were the states where the majority of cases of aerial pesticide applicator crashes (62%) occurred. This is similar to a 1992-2001 group study where these same states comprised 70% of crashes during the study. These states have extensive rural areas and are important agricultural centers in the United States. The top ten states for agriculture output are as follows: California 13.2, Texas (6.84%), Iowa (6.07), Nebraska (4.88%), Minnesota (4.06%), Illinois (4.02%), Kansas, (3.94%) North Carolina (3.40%), Wisconsin (2.85%), and Florida (2.84%). Texas (248,800 farms and ranches accounting for 130.2 million acres of land) and California (1/3 of the U.S. vegetables and 2/3 of the U.S. fruits and nuts are grown in California) are major agricultural centers in the United States so their need and use of pesticide applicators is greater than other states. Due to their vast land size, aerial pesticide application is the most feasible and economically sound way to apply pesticides [15].

A limitation of our study is that basic demographic information (age, race, gender, etc.) was missing from the dataset. Another limitation in the study may be due to the dataset used in this study. The AIDS database only contains incidents or events that do not meet the aircraft damage or personal injury thresholds set by the NTSB accident definitions. Crashes might not be reported to the NTSB or the FAA due to the operator not wanting to bring attention to the crash or the pilot decides not to report the incident for whatever reason or it is also possible that the crash was not serious to warrant an investigation. If crashes are not reported they cannot be included in the dataset. This may explain why few injuries were reported and the lack of statistical significance. Direction or response bias could be an issue as if the crash was not reported by the pesticide operator the FAA would not investigate.

Recommendations to reduce crashes are scouting the land before flying to identify obstacles (power lines, trees and manmade objects, etc.) and removing obstacles from the path/area of the pesticide applicator. Companies that are involved in aerial pesticide application should ensure up to date training on the latest technology and safety systems and provide periodical training for on safety procedures. Continued safety courses are necessary, as is proper marking of towers and other safety measures to save lives, money and time in the aerial pesticide application industry.

Training could include runs that show the applicator how to maneuver to avoid obstacles and apply pesticides to avoid drift. The NAAA [2] developed the Professional Aerial Applicators’ Support System (PAASS) in which they provide training to pilots and safety education on topics such as safety, security and drift migration. The NAAA also operates a Self- Regulating Application and Flight Efficiency program (SAFE), which is basically a “fly-in” clinic where aerial applicators can go to have their aircraft professionally analyzed. Self-employed aerial pesticide applicator pilots should pursue outside training periodically. There are several risk assessment and training tools available for pilots, for example the FAA provides a checklist for risk assessment and risk reduction for flights into terrain [9]. The FAA also produces a tool “Aerial Decision Making” in which pilots give their recommendations/action suggestions or what has worked for them in different situations [5]. The National Agricultural Aviation Association Research Education Foundation produces a Professional Aerial Applicator Support System, which provides support to aerial applicators in the hopes of reducing illness and injury in the field of agricultural pesticide application [5]. The NAAA also strongly urges the FAA to provide guidance on marking obstacles with a major recommendation/urging to expand FAA tower marking regulations to include guide wires and freestanding towers that are higher than 50 feet [15]. Also, continued training is required by some if not all states for license renewal. Additional recommendations for reducing aerial pesticide accidents include that federal research monies be continued for aerial pesticide research in the aviation sector. The National Agricultural Aviation Association [3] (NAAA) is pushing the FAA to continue funding for providing educational classes on aerial pesticide application.

Conclusions

This study provides an update to aerial pesticide applicator groups and the factors associated with related crashes as the last literature published on this topic was in the early 1990s. Aerial pesticide application is an important and readily utilized method in the United States to treat crops and for public health importance (i.e., mosquito spraying after hurricanes) While our study did not find many fatalities and injuries, aerial pesticide application is recognized as a very dangerous profession. While it appears that aerial pesticide applicator crashes have declined over the last 18 years, more research into underlying factors is needed. For example, research needs to be undertaken to examine the relationship of these factors: total flight experience of the pilot, flight phase of the aircraft when it crashed; age of pilot; toxicological studies such as drug/alcohol use and pesticide contamination of the pilot. It is also important to retain federal funding for agriculture and agricultural related activities as USDA economists have determined every one dollar spent on this research gives a return of $20 to the United States Economy [16].

Acknowledgments

The authors would like to thank Dr. Wui Bian for her advice and encouragement on the statistical analysis used in this paper. The author would also like to thank Annie Hirsch, Dr. Jessica Rinsky, Captain (Dr.) Aaron Fleischauer, USPHS and Sara Smith for their proof reading and input.

References

- Bensyl DM, Moran K, Conway GA (2001) Factors associated with pilot fatality in work-related aircraft crashes Alaska, 1990-1999. American journal of epidemiology 154: 1037-1042.

- Bureau of Labor Statistics (2012) Commercial Pilots. Available at: https://www.bls.gov/oes/current/oes532012.htm

- California Department of Food and Agriculture (2015) California Agricultural Production Statistics. Available at: https://www.cdfa.ca.gov/statistics/

- Cantor KP, Silberman W (1999) Mortality among aerial pesticide applicators and flight instructors. American Journal of Industrial Medicine 36: 239-247.

- Centers for Disease Control and Prevention (2004) Work-related pilot fatalities in agriculture-United States. MMWR Morb Mortal Wkly Rep 53: 318-20.

- Ebel R, Borchers A, Carriazo F (2007) Major uses of land in the United States. US Department of Agriculture, Economic Research Service.

- Facts about the Aerial Application Industry (2015) Available at: www.agaviation.org/content/facts-about-aerial- application-industry.

- Federal Aviation Administration (2011) Federal Aviation Regulations/Airman’s Information Manual.

- Federal Aviation Administration (1994) Flight Safety Foundation CFIT Checklist. Available at: https://www.faa.gov/regulations_policies/handbooks_manuals/aviation/risk_management_handbook/media/rmh_appc.pdf

- Illinois Department of Agriculture (2015) Aerial Pesticide Application Q and A. Available at: https://www.agr.state.il.us/Environment/Pesticide/aerialap.html

- National Agricultural Aviation Association. Available at: https://www.agaviation.org

- Texas Department of Agriculture (2015) Texas Ag Stats. Available at: https://www.texasagriculture.gov/About/TexasAgStats.aspx

- Tyrell, Scott (2013) Aerial application and the 101 critical days of summer. AgAir Update, AG Aviation’s Newspaper. Available at: https://agairupdate.com/article_detail.php?_kp_serial=00001816

- United States Department of Agriculture (2015) Economic Research Service. Available at: https://www.ers.usda.gov/data-products/agricultural-productivity-in-the-us.aspx

- Wang HH, MacMahon B (1979) Mortality of pesticide applicators. Journal of Occupational and Environmental Medicine 21: 741-744.

- Wiant CJ, Baker SP, Marine WM, Vancil R, Keefer SM (1991)Work-related aviation fatalities in Colorado 1982-1987. Aviation, space, and environmental medicine 62: 827-830.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences