ISSN : 2249 - 7412

Asian Journal of Plant Science & Research

Deployment of Truculent Species (Prosopis juliflora) as A Source of Bio Energy

1Department of Life Science, Bhakta Kavi Narsinh Mehta University, Junagadh, Gujarat, India

2Department of Chemical Engineering, Annamalai University, Tamilnadu, India

Abstract

Green fuel also known as biofuel which one is ecofriendly and sustainable resources of energy. This one is the vision for green future. Prosopis juliflora pods are easily obtain from arid and semi-arid region this plant species grows worldwide. Nearly India covered37% of the area by semi-arid zone. The aim of this study was to explore the prospects of Prosopis juliflora pods for bio-ethanol production and its solid waste for soil fertility. Parameters mainly sulphuric acid concentration taken (0.5-4 molar), hydrolysis times taken (5-35 min), fermentation times taken in broad (6-72 hr), fermentation temperature generally (25°C - 40°C) and pH acidic to basic 4-8. Saccharomyces cerevisiae yeast also used in production of bio-ethanol for fermentation. Result evaluated that we obtained the high bioethanol at sulphuric acid concentration was 1.5 M (4.2% v/v), fermentation time was 48 hour (5.1% v/v), hydrolysis time was 20 min (5.60% v/v), fermentation temperature was 30°C (5.60% v/v) and pH was 5 (5.9% v/v). Sugar contains found at high (93% v/v) when sulphuric acid concentration is 1.5 M. Further that solid waste has more assess value because that solid waste of pods biomass uses as a fertilizer which one increases fertility of soil.

Keywords

Prosopis juliflora, Bio-ethanol, Hydrolysis, Fermentation, Bio-char, pH, Temperature

Introduction

Sustainable development of the renewable resources is an important of environmental sustainability and, therefore, this thought is gaining a lot of advantages. In since last year’s industrial revolution take their broad platform in environment in the green solution for us are plants. Plants which have capacity to provide all raw material for human as well as environment. With help of plants base human can create whole world plants growth need fertile soil but some plants grow in anywhere with their influence [1]. Prosopis juliflora is one of the fastest and easiest growing trees which have the more potential to product substitute like food crops for bio-ethanol production juliflora- spices found across a planetary geographical locality [2]. Gujarat is the most favourable for this species and nearly 20% arid area out of which Prosopis juliflora covered.

Prosopis juliflora is one of the most word wide spread plant species. Which growing in soil or water with very high concentrations of metals, it is a deep-rooted plant. Perennial tree/shrub species, with a member of the family Fabaceae and an indicative species of the Desert Ecosystem. It is a deciduous, thorny, invest and deep-rooted shrub or tree that grows up to a height nearly of 10 m, according on the changeability of climatic conditions, and has been indicate to be the only tropical species capable of growing in a more variety of soils and environmental conditions [3]. It has a thick, rough, garish -green bark that show scaly with age. Stem is irregular with sharp thorns. P. juliflora is seen widely found in arid and semiarid area of Rajasthan, India, it is a fuel wood source in many regions, as well as, used as timber and grain. In more to the above uses, P. juliflora is also useful for control of soil erosion .in many developing countries, and especially in rural colonies, 2.5 billion people in biomass, to use their energy needs for cooking [4,5].

The fruiting pods of Prosopis juliflora produced are legume, Prosopis juliflora is an exotic lignocellulosic contain species [6]. Sugar contain is high in, starches, as well as protein. The pods are used as a source of food for human being in history, however, it has turned out to be less very important for human food, Pods of all Prosopis juliflora are contain of an exocarp, and sometimes fleshy layer mesocarp, fibrous endocarps and seeds are hard in nature species to species ratio of mesocarp is different, some have high ratio [7]. In World high demand for high energy resources of petroleum energy resources and interactive about worldwide climatic changes has necessary to to the recreate in the development of alternative source of liquid fuels. Ethanol has always been concluding as a better source for environment. Developing ethanol as a liquid fuel its current role for energy fuel oxygenate, as well this one is renewable and low-cost resources for world [8].The major alkaloid juliflorine contain found in this P. juliflora is used in the management of Alzheimer’s diseases. The fruits pods extract from the plant species is effective in synthesis of lepidopteran larval mortality, and has the capacity to increase the antioxidant properties and immune enzymatic activity. The pods of this plant have also used traditionally for of diabetes mellitus [9].

Materials and Methods

Sample Collection

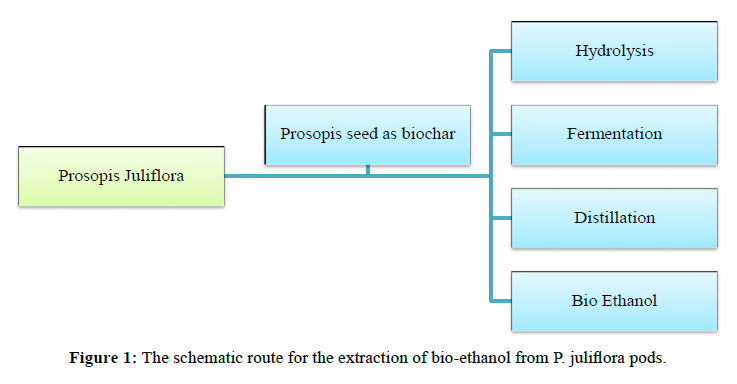

The pods of P. juliflora were collected from village Bamnasa (Ghed) (21.3796 N, 70.1557 E), Dist. Junagadh, Gujarat, India. The dry pods were selectively collected from Vigorous P. juliflora trees. For further work the collected sample pods were taken in zip bag and dispatched to laboratory. The study was conducted in a laboratory at Department & Junagadh, subsequent the methods revealed in Figure 1 [10].

Dry and Milling

Naturally dried pods of P. juliflora were broken down to a fine powder using a hammer mill process and also seeds were separated. As per the previous study seeds were used as a feed stock of bio char and only the pods were carried out for experimental study. The crushing increased surface area of the pods and enhance the contact between starch and acid or water.

Determination of Moisture Content

The P. juliflora pod was dried using an oven at 110°C followed by cooling in a desiccator over silica gel (0% relative humidity) and weighing until a constant weight. The moisture content was determined as in equation:

Moisture content (%)=(w1-w2)/w1×100

Where w1 and w2 are the weights of the sample before (g) and after drying (g), respectively

Hydrolysis

For Hydrolysis, different 08 concentrations of H2SO4 (sulphuric acid) each of 0.5, 1, 1.5, 2, 2.5, 3, 3.5 and 4 M with 250 ml of distilled water in 500 ml flask and 25 g of P. juliflora pod powder were taken and distinctly heated at 95°C for 15 minutes. After hydrolysis, the liquid fraction was cooled, filtered with filter suction and determined for glucose concentration. The distilled water and acid hydrolysates were adjusted to pH 4-5 by adding concentrated sulphuric acid and 2N sodium hydroxide, and the solutions were filtered and prepared for fermentation [11].

Fermentation

Yeast for Fermentation

The Brewer’s Yeast (Saccharomyces), purchased from the local market were used in the experiments. Firstly, Brewer’s Yeast was dissolved in warm water and after 10-15 min it being used. After that it were taken into the flask containing hydrolysate sample. As per the review batch fermentation of hydrolysis was carried out in 500ml flask with 5g/1 Brewer’s Yeast at 30°C [12].

Ethanol Fermentation

To select the best treatment for bio-ethanol production, the substrate was ferment under anaerobic condition in Brewer’s Yeast for 24hr with different concentration of H2SO4 (0.5, 1, 1.5, 2, 2.5, 3, 3.5 and 4 M). The substrate with the best bio-ethanol yield was subjected for optimization with hydrolysis times (5, 10, 15, 20, 25, 30 min), pH (4, 5, 6, 7 and 8), fermentation temperatures (25°C, 30°C, 35°C and 40°C) and different periods of fermentation times (6, 12, 24, 36, 48 and 72 h) keeping the adjusted factors constant [13].

Retrieval of Bioethanol

With the help of fractional distillation method bio-ethanol was separated from fermented sample. The solution of fermentation was heated to force the bottommost boiling substantial into the vapour phase. The vapours were passed over the fractional column and the vapour was condensed to a liquid in the horizontal condenser that was cooled by a flow of cold water. The distillate was collected in a receiver. The weight of the distillate was measured.

Yield Calculations

First, the gram of bio-ethanol was calculated based on the collected amount and concentration of bio-ethanol and expressed on a weight basis. The bio-ethanol yield was then calculated based on the gram of bio-ethanol and the sample taken.

Ge=(Ce×Ac)100

Where Ge, Ce and Ac are the gram of bio-ethanol (g), concentration of bio-ethanol and the amount collected (g)

Yield of bioethanol % =(Gram of bioethanol g )/(Sample g )

Determination of Sugar Contents

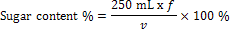

To determine the reducing sugar concentration Fehling method was used. Mixture of 2ml of conc. HCl, 10 ml distilled water and 50 ml of hydrolysed sample was heated for 10 min. The acquired sample was neutralized by adding NaOH and prepared in 250 ml conical flask and taken into the burette. 90 ml of distilled water and 10 ml of Fehling solution was taken in 250 ml flask and Methyl blue indicator was added. The conical flask solution was titrated with burette solution in boiling conditions until disappearance of blue colour and the volume at which brick red colour observed were recorded. For each sample the sugar content was calculated by using the formula given below:

Where the f-Fehling factor (0.051); v–volume used in the titration (titrate value) (ml)

Result and Discussion

Effect of Acid Concentration on Sugar Content

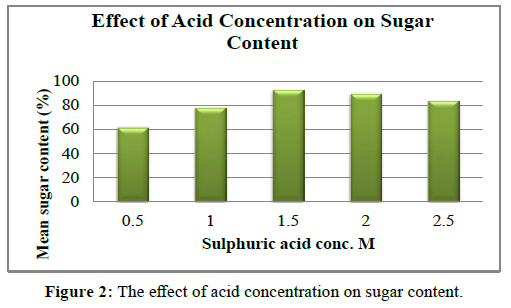

In this study, the sugar content found from P. juliflora. The sugar content increase with an increase in sulphuric acid (H2SO4) concentration up to 1.5 M, and at that particular concentration sugar content was obtained 93%. Then after an increase in sulphuric acid (H2SO4) concentration led to a decrease in sugar content. Due to a complete and fast conversion of cellulose to glucose and hemicelluloses to C5-sugars may result an increase of sugar contents in acid treated samples with increasing acid concentration Figure 2 [14].

Parameters Affecting Bio-ethanol Production

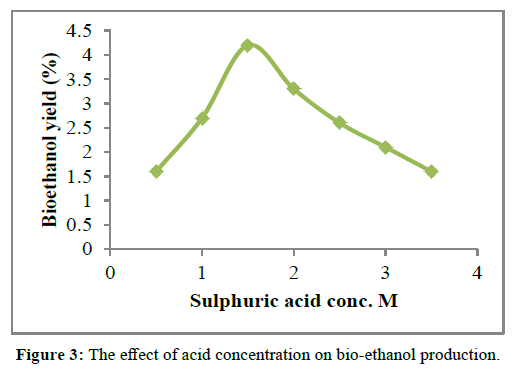

Acid Concentration: While keeping all parameters constant, 95 °C hydrolysis temperatures, 20 min hydrolysis time, pH 5, 24 hr fermentation time and 30 °C fermentation temperatures were applied for all concentration samples; the maximum bioethanol yield of 4.2% v/v was obtained in 1.5 M of H2SO4 concentrations. As shown in Figure 2, on increasing the concentration of acid decreasing bioethanol yield may be due to degradation of monomeric sugars to undesirable by-products Figure 3 [14].

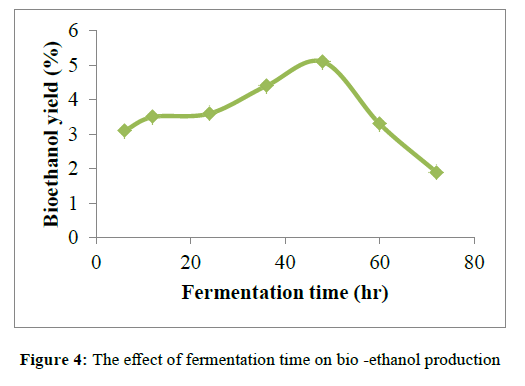

Fermentation Time: For the optimization of fermentation time for bioethanol production adjusted 6-72 hr consider with keeping all parameter constant i.e., 95°C hydrolysis temperatures, 20 min hydrolysis time, pH 5, 1.5 M acid concentration and 30°C fermentation temperatures indicated the extreme amount of bioethanol was obtained at 48 hr fermentation time. On increasing in time, the yield of bioethanol decreased may be due to microorganisms consume sugar Figure 4 [15].

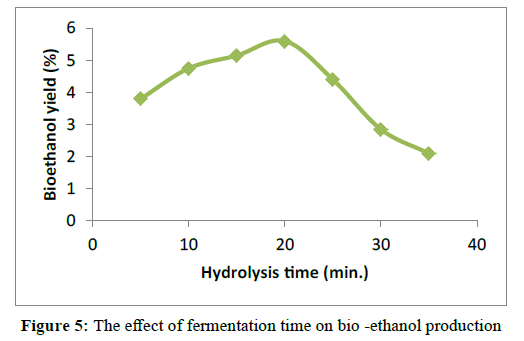

Hydrolysis Time: As another parameter hydrolysis time was taken and as results showed in Figure 4 that the bio-ethanol yield increases with increasing hydrolysis time and reaches optimum at 20 min hydrolysis time. The bioethanol yield was decreased farther than 20 min as hydrolysis time increases, may be due to the fact that longer residence time makes the sugars further oxidize Figure 5 [13].

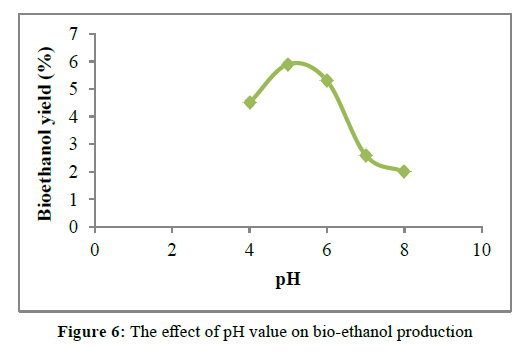

Fermentation Temperature: At 25, 30, 35, & 40°C the optimization of fermentation temperature was carried out while taking all other parameter constant i.e., 20 min hydrolysis time, 95°C hydrolysis temperatures, pH 5, and 1.5 M acid concentration. However, increasing the temperature beyond 30°C decreased the bio-ethanol yield of P. juliflora pods mash. As shown in Figure 5, the bio-ethanol yield was found maximum at 30°C (5.60% v/v). High temperature destroys yeast, and low temperature reduces speed down yeast activity Figure 6 [16].

pH Value: As a final and important parameter pH, the maximum bioethanol yield was observed at pH 5. It is worthwhile to mention that the concentration of bio-ethanol obtained (5.9 %v/v) by the hydrolysis of the Prosopis julflora pods mash is satisfactory as shown in Figure 6 [17-18].

Conclusion

In the proposed this study we would like to developed a suitable methodology that would provide biofuel by fermentation method with higher calorific value. This will result in the value addition of less explored Prosopis juliflora which is abundant in Gujarat state . And purpose of this paper will give an idea about which plant species found in bare area which is more valuable for society. In now condition fuels rent increased day by day with help of this we try to give some methods for production of eco-friendly fuel with low cost. In this method one is side product is Biochar which is more efficient for fertility of soil and growth of plant. The ratio of bioethanol production high with sulphuric acid concentration is 1.5M and maximum fermentation time is 48 hours with pH is 5. Bioethanol production ratio is not increased with decreased different parameter like concentration of acid, pH, fermentation time etc. it’s a vary to different condition. We can use bioethanol in primitive level for as a fuel with low cost. This study provides a green solution for alternative source for fuel.

References

- Sheikh AE, Ali El-Keblawy, Purushothaman CA. Sustainability Analysis of Prosopis juliflora (Sw.) DC Based Restoration of Degraded Land in North India. 2020.

- Julius MH. Mohamed Hussein Omar Prosopis Juliflora in Asals of Kenya: A Friend or A Foe Plant. International Journal of Scientific and Research Publications. 2020, 10(3).

- Transgenic Plant Technology for Remediation of Toxic Metals and Metalloids Book. 2019.

- Zuzarte F. Ethanol for Cooking - Feasibility of Small-scale Ethanol Supply and its Demand as a Cooking Fuel: Tanzania Case Study. KTH School of Energy and Environmental Technology, Heat and Power Technology. 2007.

- Rajeshwari M, Ganeshan P, Raja K. Optimization and Biodiesel Production from Prosopis Julifera Oil with High Free Fatty Acids. Journal of Applied Fluid Mechanics. 2018, 11(1):257-270.

- Swathi M, Sriganesh G, Pramod K. Upgrading Prosopis juliflora to biofuels via a two-step pyrolysis – Catalytic hydrodeoxygenation approach fueal. 2020, 267:117320.

- Hailea M, Hishea H, Gebremedhinb D. Prosopis juliflora Pods Mash for Biofuel Energy Production: Implication for Managing Invasive Species Through Utilization. Int Journal of Renewable Energy Development. 2018. 7(3):205-212.

- Gupta R, KantSharma K, ChanderKuhad R. Separate hydrolysis and fermentation (SHF) of Prosopis juliflora, a woody substrate, for the production of cellulosic ethanol by Saccharomyces cerevisiae and Pichia stipitis-NCIM 3498. Bioresource technology. 2009, 100(3):1214-1220.

- Ravi B, Vasudeva N, Sunil S, Sneha D. Investigation on Biomolecules in Ethanol Extract of Fruits of Prosopis Juliflora (Sw.) DC. Using GC-MS. Journal of Herbs, Spices & Medicinal Plants. 2018.

- Haile M, Hishe Teferi H, Gebrehiwot DG. Prosopis juliflora pods mash for biofuel energy production: Implication for managing invasive species through utilization. Int Journal of Renewable Energy Development . 2018. 7(3):205-212.

- Dawson L, Boopaty R. Cellulosic Ethanol production from sugarcane bagasse without enzymatic saccharification. Bioresources. 2008, 3:452-460.

- 12.Thuesombat P, Thanonkeo P, Laopaiboon L, Laopaiboon P,Yunchalard S et al. The batch ethanol fermentation of Jerusalem artichoke using saccharomyces cerevisiae. Journal of sciences and Technology. 2007, 7:93-96.

- Ayele K, Mesfin R, Araya, A. Potential of Bioethanol Production and Optimization Test from Agricultural Waste; the Case of Wet Coffee Processing Waste (Pulp). International Journal of Renewable Energy Research. 2012. 2(3).

- NutawanY , Phattayawadee P, Pattranit T, Mohammad N. Bioethanol Production from Rice Straw. Energy Research J. 2010,1:26-31.

- Weil J, Dien B, Bothast R, Hendrickson R, Mosier N, et al. Removal of fermentation inhibitors formed during pretreatment of biomass by polymeric adsorbents. Ind Eng Chem Res. 2002, 41:6132–6138.

- Hoi W. Potential of biomass utilization for energy in Asia Pacific experience of the Philippine situation, Forest Research Institute. 2003.

- Joshi B, Raj Bhatt M, Sharma D, Joshi J, Malla R, et al. Lignocellulosic ethanol production: Current practices and recent developments. Biotechnology and Molecular Biology Review. 2011. 6(8):172-182.

- Mohammad J, Taherzadeh ,Gustafsson L, Niklasson C, GunnarLidén et al. Inhibition effects of furfural on aerobic batch cultivation of Saccharomyces cerevisiae growing on ethanol and/or acetic acid. Bioengineering. 2000, 1(1): 374-380.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences