ISSN : 2249 - 7412

Asian Journal of Plant Science & Research

Analysis of Coffee Value Chain: The Case of Yirgachefe District, Gedeo Zone, Southern Nation Nationalities and Peoples Regional State, Ethiopia

Tizazu Toma Dilebo*

Department of Socio-economics, Southern Agricultural Research Institute (SARI), Hwassa, Ethiopia

- *Corresponding Author:

- Tizazu Toma Dilebo

Department of Socio-economics,

Southern Agricultural Research Institute (SARI),

Hwassa,

Ethiopia,

Tel: +251916860111;

Email: tomatizazu@yahoo.com

Received date: August 02, 2019, Manuscript No. AJPSKY-19-836; Editor assigned date: August 07, 2019, PreQC No. AJPSKY-19-836 (PQ); Reviewed date: August 21, 2019, QC No. AJPSKY-19-836; Revised date: February 16, 2023, Manuscript No. AJPSKY-19-836 (R); Published date: March 16, 2023, DOI: 10.36648/2249-7412.13.3.048

Citation: Dilebo TT (2023) Analysis of Coffee Value Chain: The Case of Yirgachefe District, Gedeo Zone, Southern Nation Nationalities and Peoples Regional State, Ethiopia. Asian J Plant Sci Res Vol.13 No.3:048.

Abstract

Coffee produced in Yirgachefe had been internationally known as the rarest and most prized coffee, especially in America. But farmers in Yirgacheffe complain that they are not benefited from the existing coffee supply and half of the coffee supplied to ECX to be exported does not fulfill the quality criteria of ECX. These might be due to some technical and socio-economic factors. Thus this study was conducted to identify those factors that reduced the quality of Yirgachefe coffee. The general objective of this study was analyzing coffee value chain and Its specific objectives were to trace the value chain of Yirgachefee coffee AS-IS from input supply to consumption, to identify all the constraints that impede the competitiveness of coffee produced in the study area in the national and global market and to determine the role of actors in the coffee value chain for the intervention. To achieve these objectives, both primary and secondary data were collected from 130 farm households, 16 traders, 3 processors and 17 consumers using pre tested semi-structured questionnaire and from different published and unpublished sources. The data collected were analyzed using descriptive statistics, mapping and narrative approach. The study result showed that there is a gap between the bench mark value chain and the existing AS-IS value chain in input supply, land preparation, production and harvesting, processing and marketing functions. Regarding input supply, shortage of improved seeds, reduced productivity due to manual operation and transmission of coffee disease due to untreated hand tools are identified as constraints on the AS-IS value chain. Absence of ploughing practice before holing and lack of holing machine were identified as constraints related to land preparation. Production problems identified were farm operations such as slashing, hoeing, pruning, stumping and de-suckering using manual tools; use of un-decomposed or substandard compost; no mulching practice; intercropping competitive non-leguminous plants and untimely uprooting the infected coffee tree. Lack of machine support and picking unripe and over ripped cherries together with the red cherry are out of harvesting problems. Quality problems due to processing mixed varieties of coffee; using pulping machines inappropriately and operating with maladjusted disk type, which creates quality problems, manual separation and shortage of drying materials such as mesh wire sacks made from fibbers, are also out of processing problems. Regarding marketing, insufficient storage units; wastage during sample taking and extra warehousing costs are identified as constraints in the AS-IS value chain. The study result indicated the need to encourage the entry of TVET, IOT and coffee, tea and spices authority to fill the gap.

Keywords

Coffee producers; Coffee value chain; ECX; Coffee processing industries

Introduction

Coffee is produced in more than fifty developing countries in Latin America, Africa and Asia and it is an important source of income for 20-25 million families worldwide. Ethiopia, the birthplace of coffee, stands first in coffee production in Africa and is the fifth largest coffee producer in the world next to Brazil, Vietnam, Colombia and Indonesia, contributing about 4.2 percent of total world coffee production. By 2011/2012, the country had produced approximately 500,000 metric tons of coffee [1].

Out of nine regional states of Ethiopia, coffee is dominantly produced in Oromia national regional state and southern nation, nationalities and people regional state. As per the regional coffee, tea and spices authority, south nations, nationalities and peoples regional state contributes around 60% of the total washed coffee and around 40% of the total unwashed coffee being supplied to domestic and international markets. Sidama and Gedeo zones are the first and the second highest producers of coffee in SNNPR.

Yirgachefe district is one of the six districts of Gedeo zone and is the highest producer of coffee in the zone. It contributed around 32.1% of the total washed coffee and around 26.4% of the total unwashed coffee produced in the zone in 2017. The total annual production of coffee in 2016/2017 was 70546 qt which was around 30.1% of the total coffee produced in the zone in 2016/2017 which is 234061 qt.

The district is internationally known for its good flavor coffee. The washed coffee of Yirgacheffe is the most famous washed Ethiopian coffee, especially in the United States (as a trademark). It has a test of blueberry overtones and aroma, with a hint of floralness and wineyness in the finish. But farmers in Yirgachefe complain that they are not benefited from the existing coffee supply while their coffee had been internationally accepted as the rarest and most prized. The other problem is that although Ethiopia has been taking part in exporting coffee to the world market, half of the total production including the one supplied from Yirgachefe is supposed to be consumed locally which implies that half of the coffee supplied to ECX to be exported do not fulfill the criteria of ECX and rated as under qualifying [2].

Therefore, these study addresses factors that contributed to under-qualification of coffee from Yirgachefe in terms of value chain analysis. In doing this, the study will address various technical, institutional and technological gaps that contributed to low quality in the value chain from input supply up to consumption.

Statement of the problem

Yirgachefe is known for its high production of coffee in Gedeo zone. It is the first in coffee production from 6 districts of Gedeo zone. Coffee produced in Yirgachefe had also been internationally known as the rarest and most prized coffee, especially in America. But farmers in Yirgacheffe complain that they are not benefited from the existing coffee supply and half of the coffee supplied to ECX to be exported do not fulfill the criteria of ECX. This implies that half of the coffee produced in Yirgachefe is being consumed domestically. This might be due to some technical, technological, institutional, managerial, socio-economic and environmental factors. Thus, this study was conducted to identify those factors that reduced the quality of Yirgachefe coffee. The study employed value chain analysis method to investigate the problem [3].

Objectives of the study

General objective: The objective of this study is to analysis the coffee value chain in SNNPR in case of Yirgachefe to identify the constraints within the chain in the pursuit of technological interventions.

Specific objectives

• To identify the value chain of Yirgachefee coffee AS-IS from input supply to consumption.

• To study international best practice to be used as a benchmark to take competitive advantage.

• To identify all the constraints that impedes the competitiveness of coffee in the study area in the national and global market.

• To determine the role of actors in the coffee value chain for the intervention.

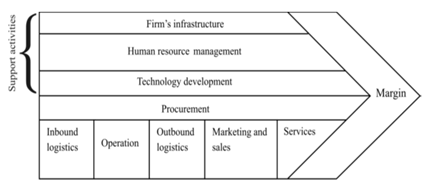

As a starting point, it is important to outline the value chain concept. A value chain disaggregates a firm into its strategically relevant activities in order to understand the behavior of costs and the existing and potential sources of differentiation. This value chain allows us to diagnose the competitive advantage of a firm or industry and to enhance this advantage by tailoring the value chain. Nevertheless, the value chain concept has evolved over the years since Porter’s definition. In the narrow meaning, a value chain includes the range of activities performed by a firm to produce a certain output. It refers to the work on competitive advantages [4]. Porter utilized the framework of value chains to assess how a firm should position itself in the market and in relation to suppliers, buyers and competitors (Figure 1).

The broad approach to value chains looks at the complex range of activities implemented by various actors (primary producers, processors, traders, service providers, etc.) to deliver a raw material to retail of the final product. The broad value chain starts from the production system of the raw materials and moves along the linkages between enterprises engaged in trading, assembling, processing, etc. This broad approach does not only look at the activities implemented by a single enterprise. Rather, it includes all its backward and forward linkages, up until the level at which the raw material produced is linked to the final consumer. In a more contemporary sense, a simple value chain could be defined as the description of a full range of activities necessary to carry a product or service from conception, through the various production stages (including physical transformation and other producer services), distribution to the final consumer and removal after its use [5]. Nonetheless, in real life applications, value chains tend to be more complex, involving several producers, creating manifold links within the value chain. Therefore it can appear that one value chain may be composed of several smaller value chains. In the context of globalization, the word fragmentation.

Methods and Materials

Description of the study area

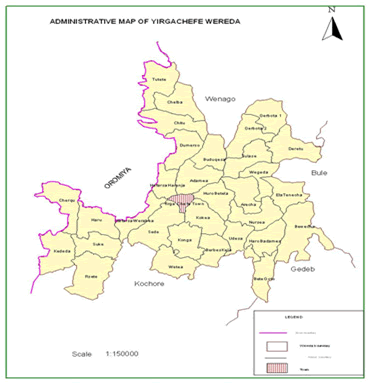

Yirgachefe district is one of the 6 districts of Gedeo zone which is located at the east-central part of Gedeo zone at a distance of 37 km from the capital city of the zone, Dila and at 127 km from the capital of SNNPR, Hawassa. Astronomically it is situated in the coordinates of 60 06′ to latitude and 380 09′ to 380 31′ east longitudes. The total area of the district was 266 sq.km and it was 60 29′ north bordered on the south by Kocher, on the west by the Oromia region, on the north by Wenago, on the east by blue and on the southeast by Gedeb.

There were around 246,573 people in the district who live being clustered in 36 Kebeles, out of which 50.3% (123997) were females and the rest 49.7% (122576) were males as per the 2013 projection of Central Statistics Agency (CSA) for the coming 4 years from 2014-2017. The total household size was estimated to be 41096. Around 87% (214,439) of the total population are living in rural areas depending on crop production and livestock rising and the rest 13% (32134) are dwellers in the urban part of the district.

The average population density is estimated to be 933 persons per square kilometer and the average land holding size of the district is around 0.65 hectare, which is much below the national average of total households’ land holding in rural areas. Agro-ecologically, the district exhibits 93% Weina Dega (midland) and 7% Dega (highland). It has to mean annual temperature ranging from 15.1°C to 20°C, elevation ranging from 1501 to 3000 masl and average annual rainfall ranging from 1201 mm to 1800 mm.

Regarding coffee production, the district was ranked as highest producer of coffee in Gedeo zone as out of the total 36 kebeles of the district, 33 were coffee producer kebeles. Of this amount, 26 are registered as high producer kebeles [6]. The total annual production for the year 2015/16 was 49464 quintals of washed coffee and 21082 quintals of unwashed coffee according to the reports of Yirgachefe coffee, tea and spices production coordination department.

The figure below shows a map of Yirgachefe district (Figure 2).

Selection criteria of coffee value chain

The coffee value chain is selected for analysis based on the selecting criteria set by federal TVET agency. First GTP-2 priority sectors were listed among them the main economic activity in the case area was identified which is agriculture. In Yirgachefe district the livelihood of the society is mainly dependent on crop production in which coffee plays a dominant role in terms of land coverage, employment, GDP share, market share, the share of export, growth potential, market potential, product diversification, conservation importance and women empowerment. Table below shows the growth and transformation plan (GTP) priority sectors from which the coffee value chain is selected (Table 1).

| Growth and Transformation Plan (GTP) | |||

|---|---|---|---|

| Priority sectors | |||

| 1 | Agriculture Crop production Coffee value chain |

4.2 | Road transport |

| 2 | Industry development | 4.3 | Shipping transport |

| 2.1 | Textile and garment | 4.4 | Air transport |

| 2.2 | Leather industry | 4.5 | Energy |

| 2.3 | Sugar | 4.6 | Water and irrigation |

| 2.4 | Cement | 4.7 | Telecommunication |

| 2.5 | Metal engineering | 4.8 | Urban development |

| 2.6 | Chemical | 5 | Trade |

| 2.7 | Agro processing | 6 | Health |

| 3 | Mining | 7 | Culture, tourism and sport |

| 4 | Economy and infrastructure | 8 | Social |

| 4.1 | Rail transport | ||

Table 1: GTP priority sectors.

Data types, sources and method of data collection

Both primary and secondary data were used to conduct this study. Primary data was collected from various value chain actors including cooperative unions, traders, exporters, producers, consumers, financial organizations, and ECX. Secondary data was collected from internet sources, published and unpublished reports. Data have been collected from primary data sources using data collection instruments such as observation, pre-tested semi structured questionnaire and check lists. During observation, availability of coffee farm, the farming system, farm tools used, traders retail shops and processors processing machines have been observed. Check lists were used to collect data from agricultural experts of the district and from experts of the district trade and industry development coordination unit, cooperative unions, financial organization, ECX experts and zonal agricultural experts to have the overall outlook on the flow of coffee throughout the value chain and the different support services delivered by value chain actors. Interview method has been employed to collect data from farmers, traders, processors and consumers using separate questionnaires [7].

Sample size determination and sampling method

Regarding sample size, 30 producers, 16 traders including ECX exporters, 3 processors (industries) and 17 consumers were arbitrarily determined as samples for this particular study due to time and budgetary constraints. Random sampling method was used to select producer farmers from 3 kebeles of Yirgachefe district. All 16 traders including ECX exporters, processors and 17 consumers were randomly selected as samples for this study.

Data analysis

Both qualitative and quantitative data collected through various methods were analyzed by using descriptive method of data analysis. The collected data from both sources were analyzed by using value chain analysis approach. Value chain map was used to depict the coffee value chain in Ethiopia explicitly. After collection of data from interview and desk study, the analysis is done by value chain analysis. Stakeholder matrix was used to show the role of chain supporters take part in the coffee value chain. Chain mapping is used to show the value chain of coffee in the country. In addition, a comparative analysis of the AS-IS value chain and the benchmark value chain of coffee had been undertaken.

Results and Discussion

Coffee value chain actors and their roles

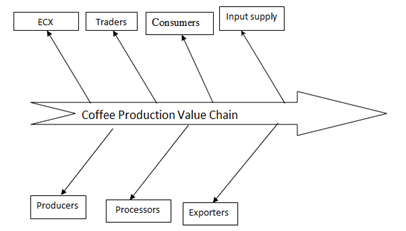

The actors participating in the coffee value chain include farmers (growers of coffee for living- to use money obtained from sale of coffee for basic needs), middlemen/intermediaries (for collection of coffee from farmers and suppliers to domestic/local market, exporter or Ethiopian commodity exchange), unions or cooperatives associations, processors (hullers and wet mills), exporting firms and local roasting firms [8].

Input suppliers: Agro-input dealers; agricultural chemicals, seedlings from research centers. Large-scale producers directly buy from international suppliers whereas the rest get from local agro-dealers. Coffee producers: The sector segmented as small-scale coffee farmers and coffee farmers’ service cooperatives, medium-sized producers and large-scale commercial private enterprises, produce for local and global market depending on the graded standard of coffee quality inspection body.

Collectors: Buy coffee from smallholder farmers at their locality and supply to processors and have a crucial role in the coffee assembly and transfer the collected coffee to the processers. Primary cooperative: Members’ collect coffee together as well as purchase others coffee in village town as a group and supply to a cooperative union.

Processors: Both dry and wet processing are carried out at processing station by processors. It includes hulling and pulping of coffee and sorting, grading packing and weighing is carried out here in large scale producers and cooperatives all processing work is accomplished by the producers by their own processing plants.

Cooperative union: Collect coffee from primary cooperative members in bulk, makes value addition practice such as hulling/processing, clearing, sorting and packaging and export directly to international buyers. In addition, Cooperative union plays a significant role in the area of market linkages with international traders, collateral for cooperatives and technical support to other cooperative and representing other cooperative members in the marketing process as well.

Wholesalers: There are private enterprises and individual that has got legal license to participate in a coffee transaction according to the regulation set by the country coffee transaction undertaken at ECX and they buy processed coffee from collectors and sell the best quality to exporters and the rejected one for domestic retailer buyers that obtained from large any sources.

Exporters: Involved in the international a transaction marketing operations buying the coffee from wholesalers at ECX and export the finished clean and standardized coffee bean.

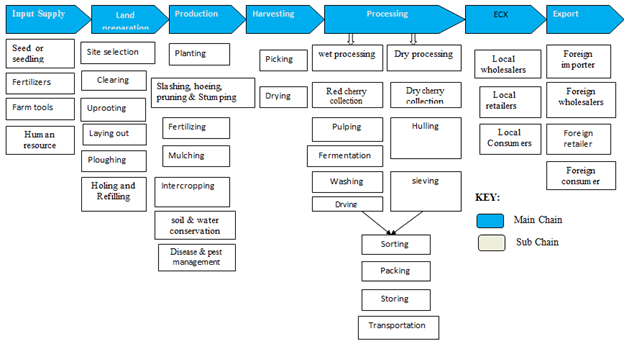

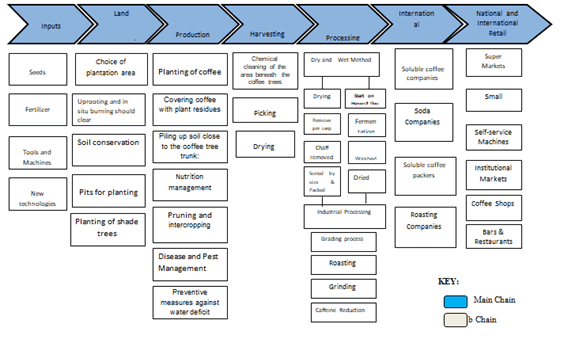

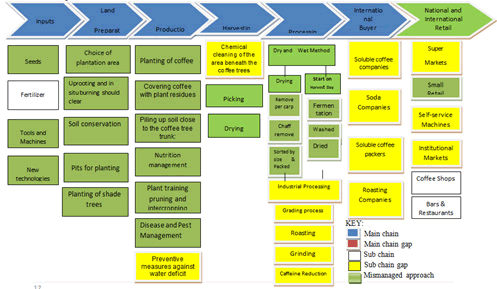

Retailers: The retailers purchase coffee from the large-scale producers, exporters and cooperative for the international market and the rejected and lower graded coffee supplied to the domestic market. Consumers: Ultimate users of coffee that can be international or domestic users (Figure 3).

Benchmarking

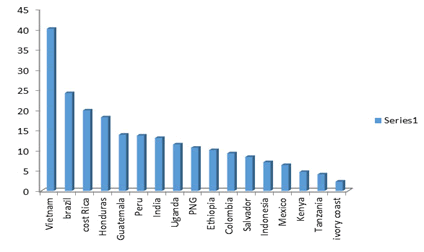

The bench mark was selected based on the total production and productivity history of countries. The following table shows the total production and productivity of the world top 10 coffee producers including our country Ethiopia (Table 2).

| Name of country | Yield per hectare per year |

|---|---|

| Brazil | 61 |

| Vietnam | 30 |

| Colombia | 13 |

| Indonesia | 11 |

| Honduras | 7.5 |

| Ethiopia | 6.5 |

| India | 6 |

| Mexico | 5 |

| Peru | 4.9 |

| Guatemala | 4.1 |

Table 2: 10 coffee producing countries by year 2017/18 in mil bags of 60 kg.

The above countries also differ in their productivity rate. The following figure also shows productivity rate of these coffee producing countries in quintal per hectare in order of their importance [9]. Therefore, brazil is selected as a bench mark for this comparative study to compare with the existing value chain of coffee (AS-IS) in Ethiopia, especially of Yirgachefe (Figure 4).

Value chain mapping

Mapping the as-is coffee value chain starting from Yirgachefe: Figure 3 below shows the AS-IS map of coffee value chain which starts from Yirgachefe where most of the coffee produced in Gedeo zone comes. The map starts from input supply and ends at export. The coffee that flows through each stage either changes its form or changes its palace from where it was produced up to export. In each stage, the different functions undertaken by respective actors have been listed. Each activity being undertaken in the AS-IS value chain is being compared to the benchmark (Brazilian experience) and mapped under the AS-IS map. The gap between Brazilian experience and the AS-IS condition are also identified and mapped [10]. This map shows what is available there in Brazil but not here in Ethiopia and functions which are available but are not being properly undertaken (Figures 5-7 and Tables 3-13).

|

Inputs used |

Constraints associated with inputs used |

|---|---|---|

| Seed | - | Shortage of improved seeds |

| Framers of Yirgachaffee mainly use 74110, 74112, 74,148, 74,158 and 1377 seed varieties | Use of substandard/unspecified seed varieties | |

| Besides, the use local varieties | Skill gap in seed preparation | |

| Coffee seed's moisture content tested with knife or tooth | Lack of convenient cold store rooms for seeds to maintain moisture at an appropriate level | |

| - | Shortage of coffee research institutes regionally and nationally | |

| Seedling | - | Manual watering |

| Seedbed preparation | The mortality rate is high in bare root planting | |

| Sowing seeds, watering (manual irrigation), sheltering, weeding | Shortage and expensiveness of plastic (poly bag) supply | |

| Bare root seedling | The mix of d/t varieties due to insufficient training and follow-up | |

| Seedlings raised in poly bags | - | |

| Fertilizer | - | An inappropriate ratio of components |

| Use of organic fertilizer or compost | An inappropriate layering of ingredients | |

| Use of locally available materials such as animal dung, biomass (coffee husk or parchment), wood ash, forest soil and bamboo and any biodegradable materials can be used for compost preparation | Lack of transportation facilities to bring parchments from coffee processing industries to farmlands | |

| Poor integration between farmers and processors | ||

| Inadequate storage for compost | ||

| Farm tools | Use of manual tools (watering cane, slashes, spade type of hoe, three prolonged hoes, pruning shear, hand saw etc) | Reduced productivity due to manual operation |

| Transmission of coffee disease due to untreated hand tools | ||

| Poor weed control | ||

| Tiresome (time-consuming) | ||

| Poor quality of farm tools | ||

| A poor linkage between farmers and farm tool suppliers | ||

| An absence of user manual for farm tools and pieces of equipment | ||

| No irrigation scheme | ||

| Human resource | - | Shortage of trained manpower |

| Farmers | The high wage rate for daily laborers | |

| Labourers | Lack of periodic skill gap training for farmers and labor force | |

| Experts | Lack of adequate extension service | |

| Trainers | Provision of inconsistent supervision by subject matter specialists and other others | |

| Supervisors | - |

Table 3: Constraints in input supply.

| Land preparation functions | Problems associated with land preparation | |

|---|---|---|

| Site selection | A place rich in decomposed plant pieces | Inappropriate slopes on the selecting areas |

| Having shed trees and windbreaks | Poor fertility | |

| Sufficient rain distribution | Deficiency in the required nutrients and minerals | |

| - | Poor treatment of soil | |

| - | Frost action and impacts | |

| Clearing | - | Tiresome and time taking manual work |

| Site clearing by slashing | Unsafe operation with hand tools | |

| Uprooting | Uprooting is undertaken by using the hoe, saw and ax | Tiresome and time taking manual work |

| - | Unsafe operation with hand tools | |

| Laying out | Laying out is carried out by using hand tools such as tape rule, line level and pegs | Shortage of appropriate hand tools |

| Lack of surveying materials | ||

| Skill gap on laying out and leveling | ||

| Plowing | It involves tilling and turns over outer and inner soil layers for coffee planting | No ploughing practice or trend before holing among farmers in the study area |

| Holing | Manual holding 3 months before planting | Lack of holing machine or equipment |

| 60 cm × 60 cm area of the hole | Inconsistency using a standard of holding dimension | |

| Putting top soil and subsoil separately after holing | Negligence in putting topsoil and subsoil separately | |

| Refilling the topsoil mixed with 2 kg of compost after two months | Untimely refilling |

Table 4: Constraints associated with land preparation.

| Main production functions | Problem associated with production | |

|---|---|---|

| Planting | Opening the refilled hole manually | Some farmers are unable to plant the seedling by keeping the collar zone |

| Planting seedlings by keeping the collar zone | Most of the farmers don’t use mulching during planting | |

| Mulching operation around a radius of 10 cm from the planted seedling | Manual operation | |

| Construction of temporary shed in the direction of sunrise and sunset (in the east-west direction) | Insufficient and inconsistent supervision | |

| - | Poor provision of extension services for farmers/producers | |

| Slashing, hoeing, pruning, stumping and de-suckering | Perform slashing operation three times in a year | Use of manual tools for all mentioned operations |

| Perform hoeing operation twice in a year | Inefficient control of perennial weeds | |

| Main pruning is performed immediately after harvesting (manually operated) | Some farmers are unable to perform the hoeing operation periodically | |

| Maintenance pruning performed at list twice per year | Some farmers are not using a temporary shedding | |

| Stamping operation is carried out after harvesting | They are not practicing proper de-suckering; it reduces productivity | |

| They are leaving many suckers beyond the optimum | Some farmers show resistance against stamping (rejuvenation) operation | |

| - | Lack of adequate stamping materials such as sow and saw blades | |

| - | Farmers often don’t use disinfectant chemicals or | |

| - | They do not disinfect their stamping tools using chemicals or fire before and after application | |

| Fertilizing application | Use of organic fertilizer or compost twice per year | Some farmers don’t use fertilizers periodically (twice a year) |

| Use of locally available materials such as green leaf, crop residue, animal manure, biomass (coffee husk or parchment), wood ash, forest soil and bamboo and any biodegradable materials can be used for compost preparation | Some farmers use un-decomposed or sub-standard compost | |

| Applying 5 kg or 5 spade per coffee tree | Some farmers don’t use the recommended amount (3 kg-5 kg per plant per round) | |

| - | Unable to use the fertilizer around the canopy and mixed with soil | |

| - | Application of compost without considering the age of the coffee tree as well as a round of practicing | |

| - | Farmers in the study area are not considering C and N ratio properly | |

| Mulching | Mulching used as a control of weeds | Farmers in the study area have not been using enough mulching materials other than enset by-products |

| It conserves soil and moisture content | They are not giving attention regarding the practicing of mulching and its real importance for the growth of a coffee tree | |

| It increases soil fertility | - | |

| Farmers in the study area are using some parts of enset such as leaves, sudo stems | - | |

| Soil and water conservation | It involves a construction of structures such as a trench, micro-basin, pet and tie ridges, etc | Practicing soil and water conservation after planting the coffee seedling rather than before |

| - | Low-quality structures that may facilitate erosion rather than be conserving soil and water | |

| - | Some farmers do not use such structures at all | |

| - | Having skill gap in designing structures | |

| Intercropping | Intercropping with haricot bean (for improving soil fertility and income generation, false banana (for shedding and consumption) and taro (for food) | Taro has a negative effect on soil fertility /competition for nutrient and water/and other non-leguminous plants |

| Helps for weed control | - | |

| Disease and pest management | Uprooting and burning the infected coffee tree on the spot | Untimely uprooting the infected coffee tree |

| Farmers have been using Coffee Berry Disease(CBD) resistant varieties such as 74110 and 74112 | Some farmers are using the infected tree for firewood (not burning at the spot) | |

| - | Not treating hand tools with chemicals and fire |

Table 5: Constraints associated with production.

| Harvesting and postharvest functions | Problems associated with harvesting and postharvest functions |

|---|---|

| Preparation of picking materials and drying bed using bamboo basket and other wooden materials | Tedious and time taking a manual operation |

| Manual picking of red cherry | Labour intensive (lack of machine support) |

| Drying or selling red cherries for processors | Picking unripe and over ripped cherries together with the red cherry |

| Supplying red cherries to processors within eight hours after picking | Some farmers are unable to meet the delivery time |

| - | Not practicing proper sorting before processing undergone |

| - | Adulteration with foreign materials and soaking in water to uplift weight |

| - | Using inappropriate picking materials |

Table 6: Constraints associated with harvesting and postharvest.

| Processing functions | Problem associated with processing | |

|---|---|---|

| Red and dry cherry collection | Red and dry cherry buying and sorting | Lack of transportation facilities and infrastructure |

| Transporting | Quality problems due to untimely arrival of red cherry for washed coffee processing | |

| - | Processing mixed varieties of coffee | |

| - | Quantity based price setting rather than quality | |

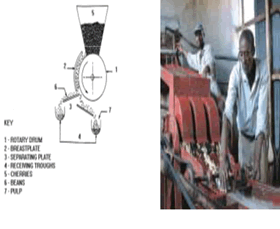

| Wet and dry coffee processing: Wet processing | It involves pulping or separating clean coffee from parchment using the pulping machine with the help of water | Using pulping machines inappropriately and operating with maladjusted disk type, which creates quality problems |

| - | Lack of trained machine operators | |

| - | Not undertaking pulping or processing washed coffee in the day at which the red cherry-picked or collected | |

| - | Not applying recirculation effectively so as to save the volume of water needed for wet processing and reducing the number of lagoons required for storing liquid by-products or sewage | |

| - | Over and under fermentation | |

| - | Some parchments are fermented with the coffee bean in the fermentation tank | |

| Dry processing | It involves milling through which the removal of husk from the sun-dried coffee so as to get clean unwashed coffee (fisher) | Manual separation |

| Sieving has been taken place for sundried coffee to separate byproducts from pure one using manually | Poor standard of hulling machines | |

| - | Time taking operation | |

| - | Not using color sorter machines to save the effort of manual sorting costs | |

| Fermentation | Removal of mucilage by soaking with water in the fermentation tank | Inappropriate application of fermentation time interval in terms of different agro-ecologies |

| - | Inconsiderate of volume, coffee bean maturity, temperature, altitude and variety during fermentation | |

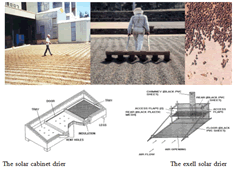

| Drying | Drying bed preparation and cemented drying floor | Insufficient drying bed and cemented floor preparation |

| Reduces moisture content in the coffee bean till it reaches 11.5% to 12% | Shortage of drying materials such as mesh wire sacks made from fibers, yellow plastic cover sheets, etc | |

| Mostly the stage of drying testing has been practiced using teeth | Lack of uniformity in drying | |

| - | Overdrying and under drying | |

| - | Lack of artificial and solar drying technologies, which are important during a heavy rainy season of coffee processing | |

| - | Lack of moisture testing instrument | |

| Sorting | Manual separation of foreign materials, broken bean, beans infected by disease and insect pests, and other defects from coffee bean | Labor intensive and time taking |

| - | Tedious manual separating of defects from the clean washed and unwashed coffee | |

| Packing | Manual packing sorted coffee in sacks (60 kg for washed and 85 kg for unwashed) | Manual operation |

| - | Less accurate | |

| - | Shortage of packing materials | |

| Storage | Storage of sacks of coffee in a separate warehouse | Using undesirable bags (plastic bags) |

| Should free from bad odor | Some farmers store in rooms where animals are living | |

| - | Not well-ventilated storerooms or warehouses | |

| - | Inappropriate and bottleneck ordering |

Table 7: Processing.

| Marketing functions | Problem associated with marketing | ||

|---|---|---|---|

| ECX | Storage services | Insufficient storage units | |

| Taking samples | Wastage during sample taking | ||

| Testing and grading | Extra warehousing costs | ||

| Auction (plays an intermediary role between coffee suppliers and exporters) | - | ||

| Exporters | Purchasing coffee from suppliers | A blending of differing traits | |

| Selling coffee to foreign importers | Unfair payment for different quality standards | ||

| - | Poor linkage with a foreign market (farmers) | ||

| Local wholesalers | Purchasing coffee from ECX | Lack of sustainable provision of coffee the retailers | |

| Selling to retailers | Always selling UG coffee to retailers | ||

| Local retailers | Purchasing coffee from ECX | Lack of sustainable provision of coffee to consumers | |

| Selling to retailers | Always selling UG coffee to consumers | ||

Table 8: Constraints associated with marketing.

| Value addition practice | Function | Existing technology |

|---|---|---|

| Input supply | Access to agricultural inputs: In Brazil, cooperatives are the main distribution channel for lime, fertilizers, agrochemicals and seeds |  |

| Seed | Variety and smart use of inputs from research and technology centre. i.e. | |

| Resilience to climate change | ||

| Resistance to pests and diseases | ||

| Improve more coffee quality | ||

| Fertilizer | Worm compost, bovine | - |

| Manure or organic compost | ||

| Tool and machines | - | - |

| New technologies | New hybrid coffee varieties: New technologies in less time-clones with desirable agronomic features like |  |

| High productivity | ||

| High quality | ||

| High vigor | ||

| Resistance to leaf rust | ||

| Shorter orthotropic inter node length |

Table 9: Input supply.

| Value addition practices | Function | Existing technology |

|---|---|---|

| Choice of plantation area | In the organic management of coffee plantations techniques for covering the soil with litter are frequently used (husks and various residues from plantations or from the agro green fertilizers (plants that are cultivated in the local or brought from elsewhere, which are incorporated to the soil with the purpose to preserve the soil fertility, which can be used as a crop rotation, live-fences, wind breakers, surrounding strips and road edges). The use of plant biomass as source of organic matter represents one opportunity for the producer to decrease their dependence in relation to the use of manure. Additionally, the soil cover protects it against erosion and decreases the incidence of spontaneous plant growth |  |

| Uprooting and insist burning should clear | ||

| Soil conservation | ||

| Pits for planting | Planting |  |

| Slightly acid (pH 5.2 to 6.3) well drained soil | ||

| Beginning of wet season | ||

| Vertical position or 30° angle | ||

| Spacing | ||

| Need light for fruit ripening | ||

| Arabica, 1350 trees/ha | ||

| Time to fruiting | ||

| Take 3-4 years to obtain mature plant | ||

| Fruit on year old wood | ||

| Planting of shade trees | Grevilea’ trees should be planted be 10 m-14 m apart |  |

| Inside the coffee plantation, the tree distribution should be approx. 70 plants/ha | ||

| Protection against frost should start three years after the trees have been planted |

Table 10: Land preparation.

| Value addition practices | Function | Existing technology |

|---|---|---|

| Planting of coffee | Slightly acid (pH 5.2 to 6.3) well drained soil |  |

| Beginning of wet season | ||

| Vertical position or 30° angle | ||

| Spacing- need light for fruit ripening | ||

| Arabica, 1350 trees/ha | ||

| Time to fruiting | ||

| Take 3-4 years to obtain mature plant | ||

| Fruit on year old wood | ||

| Covering coffee with plant residues | Another way to prevent frost damage is to cover coffee plants with a thick layer of plant residues the day before suspected frost. After the frost risk is over, this protective layer should be removed. This procedure promotes complete protection against severe frost-it is crucial that there is adequate covering of the coffee plantation for it to be effective | - |

| Piling up soil close to the coffee tree trunk | - | - |

| Nutrition management | Prominent role of in caper: Developing, transferring and assisting farms (especially small ones) to adopt new technologies |  |

| Mulching, irrigation, fertilizer and pests management; pruning; etc. | ||

| Plant training pruning and intercropping | Cyclic pruning program |  |

| Increased average productivity and reduced labor costs | ||

| Coffee sustainable curriculum implemented | ||

| Disease and pest management | - | - |

| Preventive measures against water deficit | - | - |

Table 11: Production process.

| Value | Function | Existing technology |

|---|---|---|

| Chemical cleaning of the area beneath the coffee trees | With the purpose of facilitating the harvest and reducing the conditions suitable for the rapid deterioration of the fruits that fall either before or during the harvest |  |

| Picking | Most done by hand | |

| Materials, such as sacks, spreaders and clothes must also be acquired in advance so that the harvest is completed within a maximum period of two to three months for large plantations | ||

| Ripe berries only pick every 8-10 days |

Table 12: Harvesting.

| Value addition practices | Function | Existing technology |

|---|---|---|

| Dry and wet method | Washed (wet) |  |

| Water under pressure | ||

| Dried-spread out to dry | ||

| Sun | ||

| Artificial heat | ||

| Dry | ||

| Initial drying done on trees spread on concrete, tile or matted surface | ||

| Immediately after harvesting, coffee is submitted to the ‘wagging’ operation, with the purpose of removing gross impurities that are mixed with the fruits | ||

| The harvested coffee must be placed immediately in the vehicle or in sacks and transported for drying on terraces | ||

| Grading process | Grinding is a means of adding value to a product |  |

| There are basically two types of grinders | ||

| Manual grinders and motorized grinders | ||

| Manual grinding mills | ||

| There are many manual grinders that could be used to grind coffee | ||

| An experienced operator can grind about 20 kg in an eight hour day. However, this is hard and boring work. A treadle or bicycle could easily be attached to the grinder, which will make the work easier. With this system, one person could grind about 30 kg in one day. | ||

| Industrial processing roasting and caffeine reduction | Roasting (370°F to 540°F) |  |

| Removes moisture | ||

| Light roast lose 3%-5% moisture | ||

| Dark roast lose 8%-14% moisture | ||

| Time (up to 30 min) determines flavor | ||

| Decreasing the amount of | ||

| Chlorogenic acid | ||

| Trigonelline | ||

| Marketing | 90 coffee cooperatives in Brazil | |

| Small farmers have the same market and technology access than the bigger ones | ||

| Integrated solution inputs, equipment and services | ||

| Cooperatives-facilitate access to: (i) Domestic and international markets and (ii) Risk management instruments (hedge) |

||

| Adding value: Investment in coffee industrialization and incentive for the production of specialty coffees |

Table 13: Processing.

Conclusion

This study was conducted in Yirgachefe district found in Gedeo zone, SNNPR, Ethiopia and had the general objective of analyzing the coffee value chain in the district. The specific objectives were to identify were to trace the value chain of Yirgachefee coffee AS-IS from input supply to consumption, to study international best practice to be used as a benchmark to take competitive advantage, to identify all the constraints that impede the competitiveness of coffee in the case area in the national and global market and to determine the role of actors in the coffee value chain for the intervention.

Coffee is the second most traded commodity in the world after oil. It is one of the major income generating commodities in Yirgachefe and the district has high potential in coffee production. It was the highest producer of coffee in Gedeo zone. The total annual production for the year 2015/16 was 49464 quintals of washed coffee and 21082 quintals of unwashed coffee. The data for this study were generated by individual interview using questionnaires and by observation using observation check list. This was supplemented by secondary data collected from different published and unpublished literatures. The analysis was made by comparing the AS-IS value chain with the bench mark value chain which is Brazilian experience. A total of 30 coffee producer households (26 male headed and 4 female headed) were randomly selected from three Kebeles found in Yirgachefe. About 16 traders, 3 processors and 17 consumers were also interviewed.

The study result indicated that there is a gap between the bench mark value chain and the existing AS-IS value chain in input supply, land preparation, production, harvesting, processing and marketing functions. Regarding input supply, shortage of improved seeds, bare root seedling, inappropriate composition in compost preparation, reduced productivity due to manual operation, transmission of coffee disease due to untreated hand tools and shortage of trained manpower are identified as constraints on the AS-IS value chain. In land preparation, constraints such as inappropriate slopes on the selecting areas, unsafe operation with hand tools, No ploughing practice or trend before holing among farmers in the study area, lack of holing machine or equipment, inconsistency using a standard of holding dimension and some farmers are unable to plant the seedling by keeping the collar zone. Production problems identified are that some farmers are unable to plant the seedling by keeping the collar zone, slashing, hoeing, pruning, stumping and de-suckering using manual tools; some farmers don’t use fertilizers periodically (twice a year); some farmers use un-decomposed or sub-standard compost; farmers in the study area have not been using enough mulching materials other than enset by-products; intercropping competitive non-leguminous plants rather than using complementary plants; untimely uprooting the infected coffee tree. Labour intensive (lack of machine support) and picking unripe and over ripped cherries together with the red cherry are out of harvesting problems. Quality problems due to untimely arrival of red cherry for washed coffee processing; processing mixed varieties of coffee; using pulping machines inappropriately and operating with maladjusted disk type, which creates quality problems, manual separation, poor standard of hulling machines; inappropriate application of fermentation time interval in terms of different agro-ecologies; shortage of drying materials such as mesh wire sacks made from fibbers, yellow plastic cover sheets and lack of uniformity in drying are also out of processing problems. Regarding marketing, insufficient storage units; wastage during sample taking and extra warehousing costs are identified as constraints in the AS-IS value chain.

Recommendations

The following recommendations are drown based on the results of the study.

• The observation by transect walk revealed that there is no farm equipment supply center in the district. Therefore, coffee producers’ cooperatives should establish farm tools and equipment’s supply centers.

• The review of literatures showed that there were limited resources to refer regarding coffee value chain of Ethiopia in general and Yirgachefe in particular. Therefore, institutes of technology in universities such as Dila university and Hawassa university should intervene in research and development to identify constraints in coffee value chain

• The observation by transect walk have shown that coffee processing industries in the district are not using the byproducts (coffee parchment, husks and liquid wastes) as alternative energy sources such as ethanol and briquettes. Therefore, the district, zonal and regional mineral and energy bureau should work in collaboration with coffee, tea and spices authority on the issue.

References

- Cook ML, Chaddad FR (2000) Agroindustrialization of the global agrifood economy: Bridging development economics and agribusiness research. Agri Eco 23: 207-218.

- Abasanbi AA (2010) Assessment of coffee quality and its related problems in Jimma zone of oromia regional state. CG Space 12: 12-13.

- Manan A, Ghafoor AH, Hashmi MA, Raza R, Shafqat N, et al. (2013) Marketing margins analysis of seed cotton in district Khanewal, Pakistan. J Sci 65: 224-227.

- Amamo AA (2014) Coffee production and marketing in Ethiopia. Eur J Bus Manag 6: 109-122.

- Omidvar V, Giannakas K (2015) The effects of fair trade on coffee growers: A framework and analysis. Agri Eco 46: 29-39.

- Jose S, Bardhan S (2012) Agroforestry for biomass production and carbon sequestration: An overview. Agro Sys 86: 105-111.

- Mbow C, Smith P, Skole D, Duguma L, Bustamante M (2014) Achieving mitigation and adaptation to climate change through sustainable agroforestry practices in Africa. Curr Opin Env Sust 6: 8-14.

- Ramachandran Nair P, Mohan Kumar B, Nair VD (2009) Agroforestry as a strategy for carbon sequestration. J Plant Nutri Soil Sci 172: 10-23.

- Torres CMME, Jacovine LAG, de Olivera Neto SN, Fraisse CW, Soares CPB, et al. (2017) Greenhouse gas emissions and carbon sequestration by agroforestry systems in southeastern Brazil. Sci Rep 7: 16738.

- Adane A, Bewket W (2021) Effects of quality coffee production by smallholders on local land use and land cover in Yirgacheffe, Southern Ethiopia. J Land Use Sci 16: 205-221.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences