ISSN : ISSN: 2576-1412

Journal of Applied Microbiology and Biochemistry

A Study to Investigate the Ability of the Fungus (Penicillium italicum) to Produce Lovastatin Compound and Test the Effectiveness of Fermented Product in Inhibiting the Growth of Isolation of the Fungus (Aspergillus fumigatus)

Amjad Deeb1*, Nawal Ali2, Hajar Nasser3 and Reem Salame4

1Department of Environmental Chemistry, Higher Institute for Environmental Researches, Tishreen University, Lattakia, Syria

2Department of Botany, Tishreen University, Lattakia, Syria

3Department of Chemistry, Tishreen University, Lattakia, Syria

4Department of Pharmacognosy, Tishreen University, Lattakia, Syria

- *Corresponding Author:

- Amjad Deeb

Department of Environmental Chemistry,

Higher Institute for Environmental Researches,

Tishreen University, Lattakia,

Syria,

Tel: 963 954477545

E-mail:amjaddeeb7@gmail.com

Received: June 15, 2020, Manuscript No. ipjamb-20-4681; Editor assigned: June 18, 2020, PreQC No. ipjamb-20-4681 (PQ); Reviewed: July 2, 2020, QC No. ipjamb-20-4681; Revised: June 28, 2022, QI No. ipjamb-20-4681; Manuscript No. ipjamb-20-4681 (R); Published: July 26, 2022, DOI: 10.36648/2576-1412.2022.6.7.33.

Citation: Deeb A, Ali N, Nasser H, Salame R (2022) A Study to Investigate the Ability of the Fungus (Penicillium italicum) to Produce Lovastatin Compound and Test the Effectiveness of Fermented Product in Inhibiting the Growth of Isolation of the Fungus (Aspergillus fumigatus). J Appl Microbiol Biochem Vol: 6 No: 7:33

Abstract

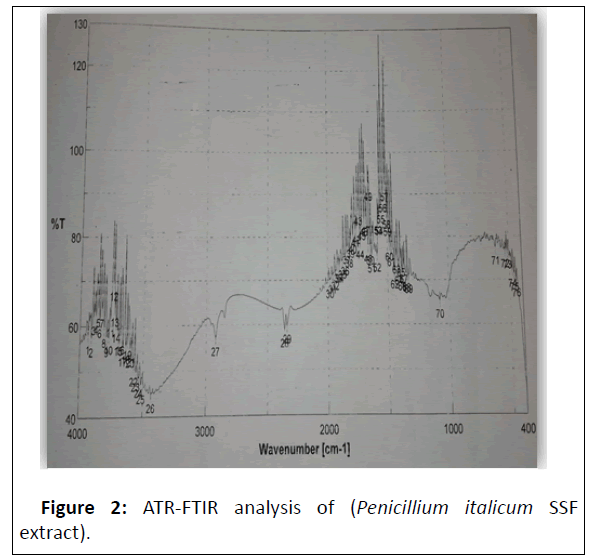

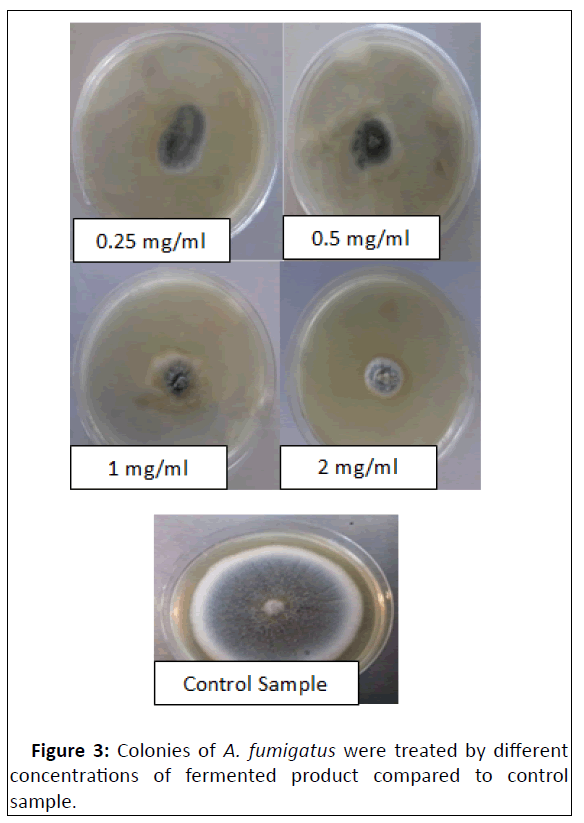

This study was carried out to investigate a possibility of the fungus (Penicillium italicum) to produce lovastatin compound by using a Solid Substrate Fermentation method (SSF) and rice powder as a substrate in it, and also to test the effectiveness of the SSF product with concentrations of (0.25, 0.5, 1, 2) mg/ml in inhibiting the growth of isolation of the fungus (Aspergillus fumigatus). The analysis of the SSF product by using ATR-FTIR showed presence several peaks belong to functional groups contain in lovastatin compound such as (alcohol O-H, C-H, C-O-H, and C-O-C). The study showed that the efficacy of SSF product in inhibiting the growth of studied fungus varied according to concentration compared to control, where the highest rate of inhibition reached 79% at concentration 2 mg/ml.

Keywords

Lovastatin; Penicillium italicum; Aspergillus fumigatus; Fermentation

Introduction

Statins are a group of drugs which used to reduce blood cholesterol with ratio 20%-60% by inhibiting the synthesis of 3-Hydroxy-3-Methyl Glutaryl COA reductase, which is the main enzyme in cholesterol biomimulation. The chemical synthesis of statins is made of units of acetate that are bound together to form chains known as polyketide [1]. On the other hand, fungi produce a wide range of biologically active compounds, some of them possess important biological activities such as antibiotics, and among the important fungal metabolites (statins), lovastatin which prepares vital source, while others produce from Chemical modifications to it, such as pravastatin, rosuvastatin, atorvastatin, simvastatin, and fluvastatin. Lovastatin can be obtained from different genera and species of fungi such as, Aspergillus, Monascus, Paecilomyces, Trichoderma, Agaricus

Lovastatin can be produced from fungi by using one of fermentation methods (Sub-Merged Fermentation (SMF), Solid Substrate Fermentation (SSF), the solid method fermentation has better advantages than submerged fermentation) (maximum utilization of the substrate, provide a good environment for fungi growth, and increase the production of statins) [2]. Example of the substrates which use in SSF to produce lovastatin include: wheat bran, rice bran, orange peels, cereal peels. In this study, the possibility of the fungus (Penicillium italicum) to produce lovastatin compound will be done by using a Solid Substrate Fermentation method (SSF) and rice powder as a substrate in it, and also the effectiveness of the SSF product will be tested in inhibiting the growth of isolation of the fungus (Aspergillus fumigatus) [3-8].

Materials and Methods

Microorganism

Penicillium italicum was isolated from soil, took a sample of the soil and planted on the Potato Dextrose Agar (PDA) and incubated at 25°C for a week, after that the studied fungi purified, then stored in the refrigerator at 4°C in tubes contain (PDA) culture [9].

Solid state fermentation

In this study, rice powder was used as a substrate to produce lovastatin, was dried at 70°C for 24 h, cooled and grounded. A quantity of 10 g of solid substrate was taken in a 250 ml of conical flask and moistened with water to maintain the moisture at 70% (v/w). Then, 40.05 g/l of potato peels powder (as a carbon source), 15 g/l of milk powder and 5.5 g/l of yeast powder (as nitrogen sources) were added to flask [10]. Then, the culture of fermentation autoclaved at 121°C for 20 min, cooled to room temperature. After that flasks were inoculated with 2 mL of fungal spore suspension (106 spore/ml). The pH was adjusted to 6.0 with 1 M HCL. Then, Flasks were incubated at 25°C for 7 days [11].

Extraction of lovastatin

At the end of SSF, the fermented material was dried at 60°C for 24 h, powdered, and 4 g of the powdered material was extracted with ethyl acetate (pH 3.0) in 250 ml Erlenmeyer’s flasks. It was then, incubated at 28°C in rotary shaker for 2 h. Then the mixture was centrifuged at 1500 rpm for 20 min. Filtration was done using Whatman filter paper No.1 for separation of fungal cell biomass from the filtrate. The supernatant was dried at 60°C to obtain fine powder [12,13].

ATR-FTIR analysis of lovastatin

Final confirmation of lovastatin in the prepared sample was done by using FTIR/Diamond ATR, ATR was fitted with a single bounce diamond at 45° internally reflected incident light providing a sampling area of 1 mm in diameter with a sampling depth of several microns [14]. A small amount of the sample was directly placed on the diamond disk. Sample was scanned for absorbance over the range from 4000 to 400 wave numbers (cm-1) at a resolution of 1 cm-1.

Antifungal activity of fermented product

The effect of fermented product was examined in inhibiting the growth of fungi (A. fumigatus) by the poison food method with some appropriate modifications. The sample was prepared at concentratios (2.5, 5, 10, 20) mg/ml. Then added 1 ml of each of the concentrations to 10 ml of the PDA culture to become the final concentrations (0.25, 0.5, 1, 2) mg/ml stirred well, then poured in plastic petri plates, left to harden at the laboratory temperature, then took a disc with a diameter of 5 mm from the sides of colony of the studied fungus by using a sterilized needle and placed in the middle of each plate. The control plates were made by Cultivate the studied fungus on the PDA culture without adding any extract, the plates incubated at 28 ± 2°C for 7 days [15-19]. The experiment was performed with three replicates for each sample and each concentration alonly and the control plates, then the colony diameter was measured in the middle of each dish, took the average growth rate of the fungal colonies of the three replicates and then calculated the inhibiting percentages according to the following equation:

Percentage of inhibition=(The average diameter of the control colony-The average diameter of the treated colony) × 100/The average diameter of the control colony.

Results and Discussion

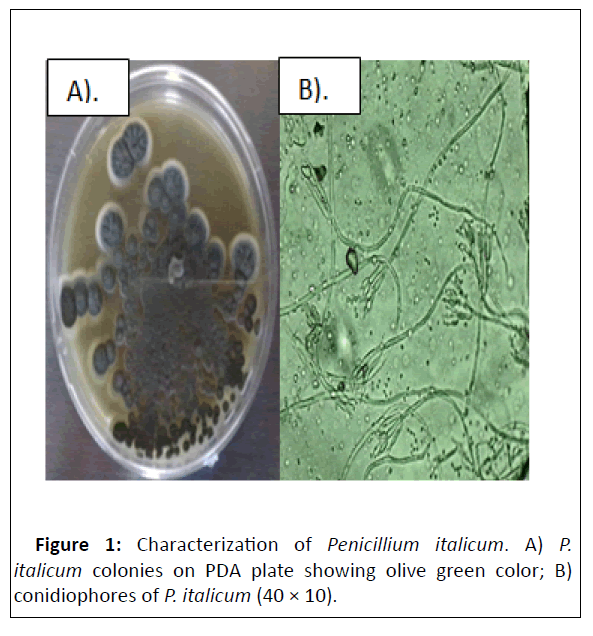

Isolation and characterization of fungal isolate from soil sample

The fungal isolate was characterized by using standard micro biological methods such as morphological and microscopic properties (Colony colour, Conidia, Phialide Conidiophores, and Metulae) [20]. Characterized and identified fungal isolate was shown in (Figure1, Table 1).

Figure 1:Characterization of Penicillium italicum. A) P. italicum colonies on PDA plate showing olive green color; B) conidiophores of P. italicum (40 × 10).

| Characteristics of fungal isolate | |

|---|---|

| Fungal isolate | P. italicum |

| Colour of top side of colony | Olive green |

| Conidia | Smooth, ellipsoidal, (3.5-4) µ |

| Phialide | Cylindrical, (8-10) µ |

| Conidiophore Branching Pattern | Terverticillate |

| Metulae | Cylindrical, (12-14) µ |

Table 1: Morphological and microscopic properties of fungal isolate.

ATR-FTIR analysis of fermented product (lovastatin)

The ATR-FTIR spectra of Penicillium italicum ssf extract (lovastatin) was shown in Figure 2. The spectrum presented characteristic peaks at 3514.63 cm-1 (alcohol O-H stretching vibration), 2950 cm-1 (olefinic C-H stretching vibration), 2360.44 cm-1 (methyl and methylene C-H asymmetric stretching), 1585.2 cm-1 (lactone and ester carbonyl stretch), 1440.87 cm-1, 1375 cm-1 (methyl and methylene bending vibration), 1342.55 cm-1 (C-O-H bending vibration), 1050.88 cm-1 (ester C-O-C symmetric bend), and 750.33 cm-1 (meta disturbed benzene-strong) confirms the presence of lovastatin in the SSF sample [21,22].

The activity of fermented product (Lovastatin) against A. fumigatus

Table 2 shows that, effectiveness varied according to the concentration, where the concentration 2 mg/ml showed the highest efficacy in inhibiting the growth of A. fumigatus by a ratio reached 78.78%, the results of the study was agreed with several studies that showed the efficacy of statins; (lovastatin, atorvastatin, simvastatin, pravasta-tin, rosuvastatin) against some microorganisms, the exact mechanism of antifungal activity exhibited by the statins is unknown, The direct cytotoxic effect of statins may possibly relate to the antifungal activity by presence phenolic compounds and aromatic alcohols are reported to have antimicrobl activity mediated by growth inhibition, lethal effect, and cytologic damage. The presence of phenolic hydroxyl groups in lovastatin may correlate with their antifungal activity. Figure 3 shows colonies of A. fumigatus treated by different concentrations of lovastatin produced by P. italicum compared to control sample [23].

| Control | 0.25 mg/ml | 0.5 mg/ml | 1 mg/ml | 2 mg/ml | |||||

|---|---|---|---|---|---|---|---|---|---|

| DIZ | % | DIZ | % | DIZ | % | DIZ | % | DIZ | % |

| 8.25 | 0 | 3.22 | 61 | 2.3 | 72 | 2.15 | 74 | 1.75 | 79 |

Table 2: The activity of fermented product (lovastatin) against A. fumigatus.

Conclusion

This study showed presence lovastatin compound as fermented product by Penicillium italicum which has antifungal properties. So that, we suggest to do further studies to Screen the production of lovastatin by other fungi and test its effectiveness in inhibiting microorganism in vitro and in vivo.

References

- Bedford DJ, Schweizer E, Hopwood DA, Khosla C (1995) Expression of a functional fungal polyketide synthase in the bacterium Streptomyces coelicolor A3(2). J Bacteriol 177: 4544-4548.

- Cabral ME, Figueroa LI, Farina JI (2013) Synergistic antifungal activity of statin-azole associations as witnessed by Saccharomyces cerevisiae-and Candida utilis-bioassays and ergosterol quantification. Rev Iberoam Micol 30: 31-38.

- Casas Lopez JL, Sanchez Perez JA, Fernandez Sevilla JM, Acie Fernandez FG, Molina Grima E, et al. (2004) Fermentation optimization for the production of lovastatin by Aspergillus terreus: Use of response surface methodology. J Chem Technol Biotechnol 79: 1119-1126.

- Chakravarti R, Sahai V (2004) Compactin: A review. Appl Microbiol Biotechnol 64: 618-624.

- Chanakya P (2011) Solid state fermentation for the production of lovastatin by Aspergillus fischeri. Res J Pharm Sci Biotechnol 1.

- Nigam VK (2015) Screening of different fungi for production of lovastatin. Asian J Biomed Pharm Sci 5: 24.

- Gupta K, Mishra PK, Srivastava P (2007) A correlative evaluation of morphology and rheology of Aspergillus terreus during lovastatin fermentation. Biotech Bioproc Eng 12: 140-146.

- Immanuel SR, Anusha P (2019) Production of lovastatin by soil microfungi Rhizopus oryzae. Acta Scient Med Sci 3: 70-74.

- Jaivel N, Marimuthu P (2010) Optimization of lovastatin production in solid state fermentation by Aspergillus terreus. Int J Eng Sci Technol 2: 2730-2733.

- Javed S, Meraj M, Mahmood S, Hameed A, Naz F, et al. (2017) Biosynthesis of lovastatin using agro-industrial wastes as carrier substrates. Trop J Pharm Res 16: 263-269.

- Lucchini JJ, Corre J, Cremieux A (1990) Antibacterial activity of phenolic compounds and aromatic alcohols. Res Microbiol 141: 499-510.

- Bizukojc M, Ledakowicz S (2009) Physiological, morphological and kinetic aspects of lovastatin biosynthesis by Aspergillus terreus. Biotechnol J 4: 647-664.

- Reddy DSR, Latha DP, Latha KPJ (2011) Production of lovastatin by solid state fermentation by Penicillium funiculosum NCIM 1174. Drug Invent Today 3: 75-77.

- Seraman S, Rajendran A, Thangavelu V (2010) Statistical optimization of anticholesterolemic drug lovastatin production by the red mold Monascus purpureus. Food Biopro Proces 88: 266-276.

- Seenivasan A, Subhagar S, Aravindan R, Viruthagiri T (2008) Microbial production and biomedical applications of lovastatin. Ind J Pharm Sci 70: 701.

- Srinu M, Bhushan GP, Moges F, Srilakshmi J, Sankar G, et al. (2010) Screening of HMG Co A reductase inhibitor producing marine Actinomycetes. Asian J Pharm Res Health Care 2: 66-74.

- Upendra RS, Pratima K, Amiri ZR, Shwetha L, Ausim M (2013) Screening and molecular characterization of natural fungal isolates producing lovastatin. J Microb Biochem Technol 5: 25-30.

- Yigit A, Korukluoglu M (2007) The effect of potassium sorbate, NaCl and pH on the growth of food spoilage fungi. Ann Microbiol 57: 209-215.

- Mouafi FE, Ibrahim GS, Elsoud MMA (2016) Optimization of lovastatin production from Aspergillus fumigatus. J Genet Eng Biotechnol 14: 253-259.

- Nazzal S, Smalyukh II, Lavrentovich OD, Khan MA (2002) Preparation and in vitro characterization of a eutectic based semisolid self-nanoemulsified drug delivery system (SNEDDS) of ubiquinone: Mechanism and progress of emulsion formation. Int J Pharm 235: 247-265.

- Ouda SM, Gabr SA, Younis NA, Said ME, Sabry AA, et al. (2015) Optimization of different parameters on lovastatin production by Aspergillus niger I-4 and Aspergillus terreus I-8 and its hypocholesterolemic effect. Res J Pharm Biol Chem Sci 6: 1439-1448.

- Panasuriya CR, Singhal RS (2010) Response surface methodology for optimisation of lovastatin production by solid state fermentation. Braz J Microbiol 41: 164-172.

- Pushpa H, Priyata H, Nomita DK, Onya N, Vijayalakshmi A, et al. (2016) Screening of lovastatin (HMG-CoA reductase inhibitor) from edible wild mushrooms. Curr Res Environ Appl Mycol 6: 190-196.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences