ISSN : 0976-8505

Der Chemica Sinica

Abstract

Influence of Relative Humidity on The Morphology of Electrospun Polymer Composites

Polymeric composites have a potential application in tissue engineering. Several parameters of the electrospinning technique and their impacts have been studied. But, the humidity effects during the process are far less explored. Two ranges of controlled humidity 30-35 and 70-75% were established to relate the impact on the fiber morphology. Binary and complex composites were fabricated by blending biopolymers and a ceramic constituent. We chose poly(ethylene oxide)/mesquite gum, poly(vinylpyrrolidone)/mesquite gum/hydroxyapatite, and poly(ethylene oxide)/chitosan/ hydroxyapatite systems, as a comparative study. In particular, mesquite gum is a biocompatible material that has not been investigated as a biocomposite and offers potential physicochemical properties. On the other hand, chitosan offers good properties for tissue engineering and has been extensively studied, however its processing remains a challenge and covers a great interest. The diameter sizes and morphology were assessed by using scanning electron microscopy (SEM) and the chemical structure was analyzed by Fourier transform infrared spectroscopy (FT-IR). Nano-scaffolds obtained, yielded nanofibers, nets and spindle-like fibers, their resultant dimensions were from 89 nm to 388 nm. These results obtained describe how much different morphological features can be induced under low and high humidity during fiber fabrication which is crucial for its later application in biological studies.

Author(s): Yanet E. Aguirre-Chagala, Víctor M Altuzar-Aguilar, Jorge G. Domínguez-Chávez, Ernesto F. Rubio-Cruz, Claudia O. Mendoza-Barrera

Abstract | Full-Text | PDF

Share This Article

Google Scholar citation report

Citations : 6019

Der Chemica Sinica received 6019 citations as per Google Scholar report

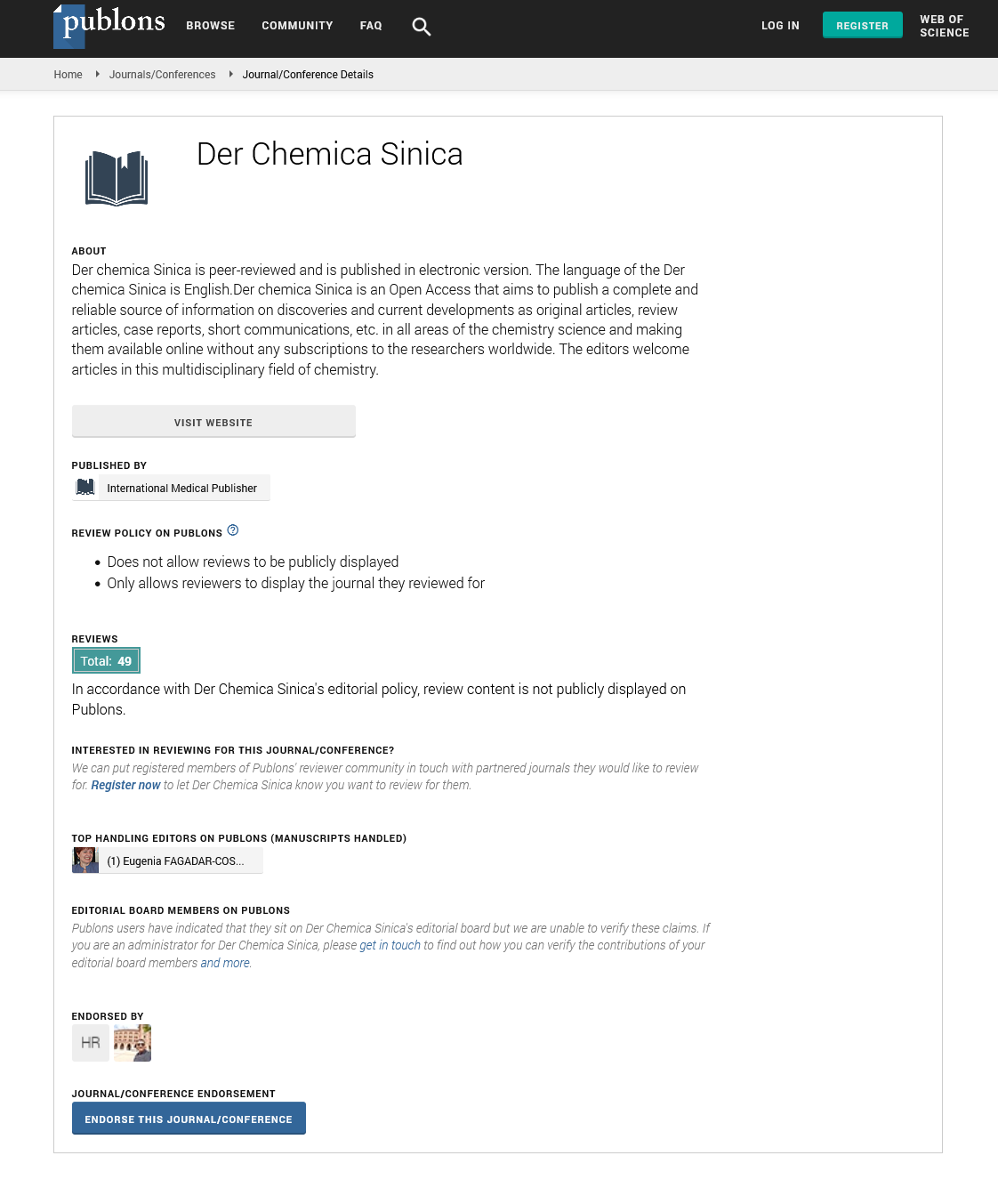

Der Chemica Sinica peer review process verified at publons

Abstracted/Indexed in

- Google Scholar

- Open J Gate

- Genamics JournalSeek

- China National Knowledge Infrastructure (CNKI)

- Directory of Research Journal Indexing (DRJI)

- Publons

- MIAR

- International Committee of Medical Journal Editors (ICMJE)

- Serials Union Catalogue (SUNCAT)

- Geneva Foundation for Medical Education and Research

- Secret Search Engine Labs

- Euro Pub

- CAS (Chemical Abstracting Services)

- University of Barcelona

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences