Level of Exposure of Occupational Respirable Dust to Underground Gold Mine Workers in Ghana

Edward Ebow Kwaansa- Ansah*, Edward Kwaku Armah and Francis Opoku

Department of Chemistry, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana

- *Corresponding Author:

- Edward Ebow Kwaansa-Ansah

Department of Chemistry, Kwame

Nkrumah University of Science and Technology

Kumasi, Ghana

Tel: +233244298182

E-mail: eekwaansaansah@yahoo.com

Received Date: August 23, 2017 Accepted Date: September 10, 2017 Published Date: September 20, 2017

Citation: Kwaansa-Ansah EE, Armah EK, Opoku F (2017) Level of Exposure of Occupational Respirable Dust to Underground Gold Mine Workers in Ghana. Glob Environ Health Saf. Vol. 1 No. 1:10

Abstract

Underground gold miners are potentially exposed to various levels of crystalline silica dust from the mining activities. In order to assess the silica content exposed to underground miners in Ghana, a study was carried out using a gravimetric dust sampler for which the samples obtained were analysed for its dust and the crystalline silica contents using an X-ray diffractometer. A total of 226 underground workers were sampled from four underground operating shafts within which six different job titles were chosen to estimate the occupational dust exposure levels. The degree of exposure to both respirable dust and crystalline silica follows in the increasing order of Class A˃Class B˃Class C. The highest mean concentration of respirable dust and crystalline silica was recorded by the Grouters (4.2614 ± SD mg/m3) and the Teledyne Operators (0.5659 ± 0.26624 mg/m3), respectively. The resulting order of respirable dust within the job titles increased in the order as Machine Drivers<Long Hole Drillers<Equipment Operators<Teledyne Operators<Blastmen<Grouters whiles that of the crystalline silica increased as Machine Drivers<Equipment Operators<Blastmen<Long Hole Drillers<Grouters<Teledyne operators. Higher silica values suggest the exposure of larger amounts of respirable dust from silica bearing rocks to these workers during underground operations.

Keywords

Underground miners; Respirable dust; Crystalline silica; Mining; Dust exposure levels

Introduction

In the past, western mining industries had little attitudinal and stringent measures towards safety. Safety was seen as costly and counterproductive, concerned more with complying industrial law rather than ensuring the health and well-being of those who worked in the industry [1]. Work in the mining sector or in general is still among the most hazardous of all occupations [2].

Mining operations such as drilling, blasting, and crushing of silicabearing rocks release various forms of dust particles. The toxicity of the dust generated is dependent on a number of factors, such as the quantity of crystalline silica inhaled, particle size distribution and exposure duration. It has also been reported that freshly fractured or broken silica, either by grinding or abrasion is more reactive and of greater toxicity than the old or stale dust [3-5] found that about 30% of free silica is in respirable gold mine dust and that the inhalation of the silica particles could be part of the pathogenic processes leading to chronic obstructive pulmonary diseases. Greaves [6] also reported that chronic silicosis is associated with moderate exposure (0.05-0.1 mg/m3) to crystalline silica over twenty to forty-five years.

Dust generated by mining activity include crystalline silica, which is mostly alpha quartz, but other forms, such as cristobalite and tridymite may also exist. According to the International Agency for Research on Cancer (IARC), crystalline silica was identified as a probable carcinogen to humans which was voted to change the classification to "human carcinogen" [7].

Silica is commonly found in rocks such as marble, sandstone, flint and slate, and in some metallic ores where larger amounts of precious metals such as gold are mined from. Silica is present in igneous rock such as marble, sedimentary rocks in the form of sandstone and metamorphic rock in the form of quartzite [8].

Pneumoconiosis is a Greek word formed by the combination of pneumonia which means lung, konis which means dust and osis which means condition. Silicosis is a special type of pneumoconiosis, though other types exist, such as black lung disease and asbestosis [9].

Silicosis is a deadly disease causing death in a very short period of time either by acute or accelerated cases. Silicosis is the major health concern in surface mining, whether hard-rock or coal. In the United States, a silicosis alert was initiated by the National Institute for Occupational Safety and Health Administration, NIOSH for drill operators. In 1996, the Mine Safety and Health Administration (MSHA) joined the NIOSH for a general alert on silicosis because of an unusually high incidence of silicosis in Pennsylvania among drill operators at surface mines.

Although silicosis has been known for centuries, the industrialisation of mining has led to an increase in silicosis cases. Pneumatic drilling in mines and less commonly, mining using explosives, would raise rock dust. In the United States, a 1930 epidemic of silicosis due to the construction of the Hawk’s Nest Tunnel near Gauley Bridge, West Virginia caused several deaths where 764 workers died of acute silicosis during the excavation of a tunnel [10]. Other accounts place the mortality figure at well over 1000 workers, primarily African American transient workers from the southern United States. The prevalence of silicosis led some men to grow what is called a miner’s moustache, in an attempt to intercept as much dust as possible.

Chronic simple silicosis has been reported to occur from environmental exposures to silica in regions with high silica soil content and frequent dust storms most especially in underground mining operations. Protective measures such as respirators have brought a steady decline in death rates due to silicosis in western countries. However, this is not true of less developed countries where work conditions are poor and respiratory equipment is seldom in use. Most other dust is considered nuisance dust; that is, long and substantial exposure could lead to some health impact, but generally the impact does not result in disability at significant rates under normal working conditions [11].

The International Agency for Research on Cancer (IARC), has also stated that there is sufficient evidence in humans for the carcinogenicity of inhaled crystalline silica in the form of quartz or cristobalite from occupational sources (IARC 1997). It is, however, important to note that occupational hazards such as dust exposures, noise, vibrations and radioactive forms of pollution can best be controlled at the source. On surface mining, dust from opencast mining and tailings becomes the biggest culprit and for underground mining, all facets of mining are much easier because it is limited to confined spaces which facilitate the control of workers exposure.

Gold deposits in some mining companies geographically occur in the Birimian graphitic phyllites and sricite-schists transverse by myriads of chutes and lenses of quartz. Some of the gold in the quartz vein are contained in sulphides, such as arsenopyrite and pyrite, that require complex techniques for separation, but the majority exists in a free state, which is easily milled.

Prolonged exposure to silica dust can result in permanent damage to the lung tissues leading to severe breathing defects. Specifically, silica dust level data are needed to provide a time exposure history for workers in addition to further information on dust sources. This information will provide the basis for targeting and selecting the various means of isolation from the sources of dust, engineering controls, administrative controls, and the use of personal protective equipment to reduce dust exposures among the mining workforce. The main objective of this study was to study the level of exposure of occupational respirable dust to underground mine workers in Ghana. The study was designed to identify the sources of the dust, to collect and analyse the dust particulates for its dust concentrations and its silica content in four shafts and selected job titles and to compare the concentration of particulate dust and silica among the various shafts and the selected job titles.

Materials and Methods

Study consent and the occupational groups

Data was collected from the underground miners working from four different operating shafts in the mines named as shaft A, shaft B, shaft C and shaft D. The job titles of interest in this study were the blastmen, Teledyne Operators, Grouters, Equipment Operators, Machine Drivers and the Long Hole Drillers. The purpose of selection of the job titles was based on the fact that much of the dust concentrations are generated at these sites during underground operations. The miners in the defined occupational groups, however, were not distinguished from other co-workers on shift duty to avoid inactivity of mining operations.

Management of the mining company was contacted and visited providing information on the sources for the study aims, selection, and involvement of study participants, study duration and benefits to both miners and the organisation. Written consent for the study was obtained from the mining company as well as the workers to be studied, with prior approval from the department of Chemistry, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana.

Personal dust sampling

Personal respirable dust sampling was undertaken on 226 underground miners selected for respirable dust sampling and every tenth cassette/filter weighed was selected for silica analysis. Personal sampling was conducted with a portable sampling pump and a sampling head placed on the worker with the inlet positioned in the ‘breathing zone’ of the worker, about 20-30 cm from the nose/mouth, on the lapel. The selected workers wore the pump and the cyclone to their places of work over the daily eight-hour shifts, at a mean temperature of 30°C and 90% relative humidity.

At least five personal samples were taken each day of the study between 6 and 8-hour duration depending on how long the miner stayed underground. Sampling pumps were switched on and the flow rates were checked just before the miner went underground. The pump flow rates were rechecked before switching off the pumps on their return at the end of the shift.

Sampling

Gravimetric pumps were mounted on the breast zones of the underground workers to collect particulates of dust within the working vicinity. Each individual was then allowed to work for eight hours, after which the gravimetric pumps were collected and analysed for their respirable dust and their crystalline silica contents using gravimetric dust sampling and X-ray diffraction techniques. This was achieved as the filter holder in the workers breathing zone was attached and the pump to the worker’s belt. The pumps were placed in a protective leather pouch with the whole harness strapped to the chest/back of the person being sampled, with the filter assembly in the workers breathing zone. The inlet of the cassette was made to face downward. The plug was removed from the cassette inlet and the pump was turned on. The start time, job title and the pump number were recorded from the underground mining workers.

Analysis of dust samples

Gravimetric analysis of respirable dust was carried out using a 5-digit ‘TARE’ BDH Electronic Analytical Balance (precision: ± 0.01 mg). All field filters with controls were weighed at the end of each sampling day. The twelve field silver membrane filters and blank filters (four) were analysed for crystalline silica (quartz) by X-ray diffraction. The filter samples were analysed following NIOSH [9] and after sampling, all field and blank filters were dried overnight in a Nalgene desiccator (containing silica gel) prior to weighing.

Statistical analysis

The data collected was analysed using Statistical Package for Social Sciences (SPSS Statistics 17.0 Incorporation 2007) software. Descriptive statistics were computed for 8 hours work shift as a time-weighted average (TWA) and correlation values obtained to determine if mean dust levels between shafts and job titles had statistically significant differences. Linear regression and residual values were however obtained from the ANOVA. The correlation was however observed to be statistically significant at p˂0.01 and p˂0.05 for most of the job titles (Teledyne Operators, Blastmen, Long Hole Drillers, Equipment Operators) except the values for Grouters and the Machine Drivers which showed no significance correlation (p˃0.05 or p˃0.01).

Results and Discussion

A total of two hundred and twenty-six (226) underground workers were involved in this study and they were represented as Shaft A, Shaft B, Shaft C and Shaft D. Job titles selected were the Blastmen, Grouters, Equipment Operators, Machine Drivers, Long Hole Drillers and the Teledyne Operators. This was based on the fact that larger amount of silica-bearing rocks are produced during the underground operations. Out of the 226 underground workers, the number of workers and the corresponding percentages for each class of silica dust was presented in Table 1.

| Job titles | Number of workers | Class A% | Class B% | Class C% |

|---|---|---|---|---|

| Blastmen | 50 | 40 | 28 | 32 |

| Machine Drivers | 45 | 44 | 33 | 22 |

| Equipment Operators | 49 | 40 | 31 | 29 |

| Teledyne Operators | 20 | 60 | 15 | 25 |

| Grouters | 18 | 6 | 17 | 78 |

| Long Hole Drillers | 44 | 46 | 25 | 30 |

Table 1: Descriptive statistical values for the Job Titles for both respirable dust and crystalline silica.

The shafts with their corresponding number of workers as well as in percentage-wise to the number of workers was presented in Table 2.

| Shafts | Number of workers (n) | Percentages (%) |

|---|---|---|

| Shaft B | 31 | 13.72 |

| Shaft A | 88 | 38.93 |

| Shaft C | 67 | 29.65 |

| Shaft D | 40 | 17.70 |

Table 2: Workers Distribution per each Shaft.

The mean concentrations of respirable dust for the four shafts ranged from 0.02-4.26 mg/m3 with Shaft A (1.07 ± 0.74 mg/m3) recording the highest mean concentration and the minimum mean concentration by Shaft D (0.88 ± 0.62 mg/m3) as presented in Table 3.

| Shafts | Range | Mean ± SD | Standard Error |

|---|---|---|---|

| Shaft B | 0.02-4.26 | 1.06 ± 0.97 | 0.174 |

| Shaft A | 0.08-4.08 | 1.07 ± 0.74 | 0.079 |

| Shaft D | 0.04-3.09 | 0.88 ± 0.62 | 0.076 |

| Shaft C | 0.02-3.52 | 0.94 ± 0.75 | 0.119 |

Table 3: Descriptive statistical values for the shafts in mg/ml (Respirable Dust Levels).

The mean concentrations of crystalline silica for the four shafts ranged from 0.02-1.03 mg/m3. Moreover, the highest mean concentration of crystalline silica was recorded by Shaft C (0.19 ± 0.25 mg/m3) and the minimum by Shaft D (0.13 ± 0.13 mg/m3) as presented in Table 4.

| Shafts | Range | Mean ± SD | Standard Error |

|---|---|---|---|

| Shaft B | 0.03-0.58 | 0.13 ± 0.14 | 0.026 |

| Shaft A | 0.02-0.92 | 0.16 ± 0.19 | 0.020 |

| Shaft D | 0.04-0.65 | 0.13 ± 0.13 | 0.016 |

| Shaft C | 0.03-1.03 | 0.19 ± 0.25 | 0.039 |

Table 4: Descriptive Statistical Values for the Shafts in mg/ml (Silica Levels).

The National Institute for Occupational Safety and Health [9] recommended exposure limits of 1.0 and 0.1 mg/m3 for respirable dust and crystalline silica, respectively. The mean concentration of dust recorded by Shaft B (1.0606 mg/m3) and Shaft A (1.0730 mg/m3) exceeded the recommended value by NIOSH for respirable dust concentration, which indicates higher amounts of dust generated in both Shaft A and Shaft B during the breaking down of larger deposits of silica-bearing rocks. Thus, this study showed a high personal respirable dust exposure levels, as well as silica content in the chosen mining company. Muir and Wang [4,12] found a lower percentage of respirable silica of 6 and 13%, respectively. Ref. [12] suggested that lower percentage of these respirable silica dust is less toxic even with comparable cumulative silica exposure levels. Greaves [6] also reported that chronic silicosis is associated with moderate exposure (0.05-0.1 mg/m3) to crystalline silica over 20 to 45 years.

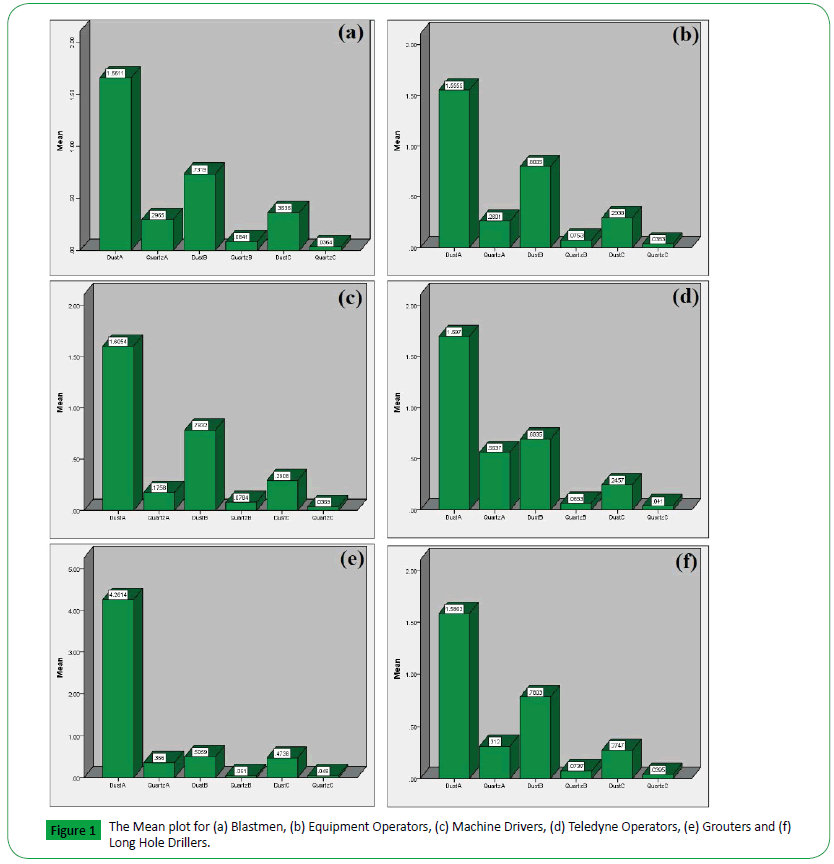

Higher concentration values give an indication of the greater extent of the exposure of respirable dust. The level of respirable dust is greatest for the grouters, followed by the blastmen, and the Teledyne operators with the exposure to machine operators being the least which suggests that lesser amounts of respirable dust are generated during their activities. The various respirable dust and crystalline silica values are shown in Figure 1.

The minimum concentration of dust for all the job titles was less than the recommended value. The minimum concentration was recorded by the Blastmen (0.3346 ± 0.118 mg/m3) and the least by the Teledyne Operators (0.223 ± 0.125 mg/m3) for respirable dust. For the silica concentration, the minimum concentration was recorded by the Long Hole Drillers (0.0393 ± 0.00366 mg/m3) and the least by the Blastmen (0.0366 ± 0.00810 mg/m3). However, all the six job titles recorded mean respirable and crystalline silica concentrations above the recommended limit. The highest mean concentration values for respirable dust and crystalline silica were the Grouters (4.2614 mg/m3) and the Teledyne Operators (0.5659 ± 0.2662 mg/m3). In a study [13] to measure the respirable crystalline silica dust exposure among United States of America workers, the overall geometric mean of silica exposure levels for 8-hours TWA samples collected during programmed inspections was 0.077 mg/m3. Surgical appliances supply industry in the same study had the lowest geometric mean silica exposure level of 0.017 mg/m3 and 0.166 mg/m3 for the metal valves and pipe fitting industry for an 8-hours TWA measurement. By comparing these reported values to that obtained in my study, it is shown that the highest value for the crystalline silica was 0.19 mg/m3 by the Shaft C compared to 0.166 mg/m3 for the metal valves and pipe fitting industry whiles the least value recorded was 0.13 mg/m3 by both Shaft B and Shaft D with values far above the recommended American Conference of Governmental Industrial Hygienists (ACGIH) threshold Limit of 0.05 mg/m3 compared to 0.017 mg/m3 for the surgical appliances supply industry.

Conclusions

The study shows that shaft C reported the highest mean concentration of crystalline silica followed by shaft A, as well as Shaft B and Shaft D. For the respirable dust concentrations, the highest mean concentration was reported by Shaft A, followed by Shaft B, Shaft C and lastly Shaft D. The Grouters and the Teledyne Operators reported the highest values for the mean concentrations for both respirable dust and crystalline silica respectively involving the job titles. The reported mean concentration values for all the four Shafts showed values higher than those recommended by NIOSH for the both respirable dust and crystalline silica. In conclusion, larger amounts of silicabearing rocks are broken down and become exposed to workers during underground mining operations hence the need for more stringent dust control measures to control this problem.

Acknowledgements

The authors are very grateful to underground miners as well as managements of the mining company for the use of their facilities for this work. We are also grateful to the Department of Chemistry, Kwame Nkrumah University of Science and Technology (KNUST), Kumasi, Ghana.

References

- Staley BG (1992) Culture shock-changing attitudes to safety in mines. Proceedings of the safety-Hygiene and Health in Mining Conference. British Journal for Industrial Medicine 1: 263-273.

- Grayson RL (1999) Mine Health and Safety: Industry’s march towards continuous improvement. The United States Experience 7: 83-100.

- Sluis-Cremer GK, Walters LG, Sichel HS (1967) Chronic bronchitis in miners and non-miners: an epidemiological survey of a community in the gold mining area in the Transvaal. British Journal for Industrial Medicine 24: 1-12.

- Wang M, Muir DF, Banks DE (1998) Airways obstruction and occupational inorganic dust exposure. Occupational Lung Disease - An International Perspective 3: 69-82.

- Hnizdo E (1992) Health risks among white South African Gold Miners-dust smoking and chronic obstructive pulmonary disease. South African Medical Journal 81: 512-517.

- Greaves IA (2000) Not-so simple silicosis: a case for public health action. American Journal for Industrial Medicine 37: 245-251.

- Carrol DW (1997) Crystalline silica update. Stone Review 13: 14-15.

- Ridley WI (2012) Petrology of Igneous Rocks volcanogenic Massive Sulfide Occurrence Model. USGS Scientific Report 15: 5-10.

- NIOSH (1999) Work Related Lung Diseases Surveillance Report.

- Burtan RC (1984) Silicosis-an ancient malady in a modern setting. Society of Mining Engineers 10: 81-84.

- Lowndes IS, Moloney K (1996) A review of diesel exhausts emission monitoring and control technology. Mining Technology 78: 275-283.

- Muir DC (1994) Toxicity of silica dust. American Journal of Industrial Medicine 25: 769-772.

- Wagner GR (1997) Asbestosis and silicosis. Elsevier 349: 1311-1315.

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences